How Shock Dynos Improve Road Safety and Vehicle Performance

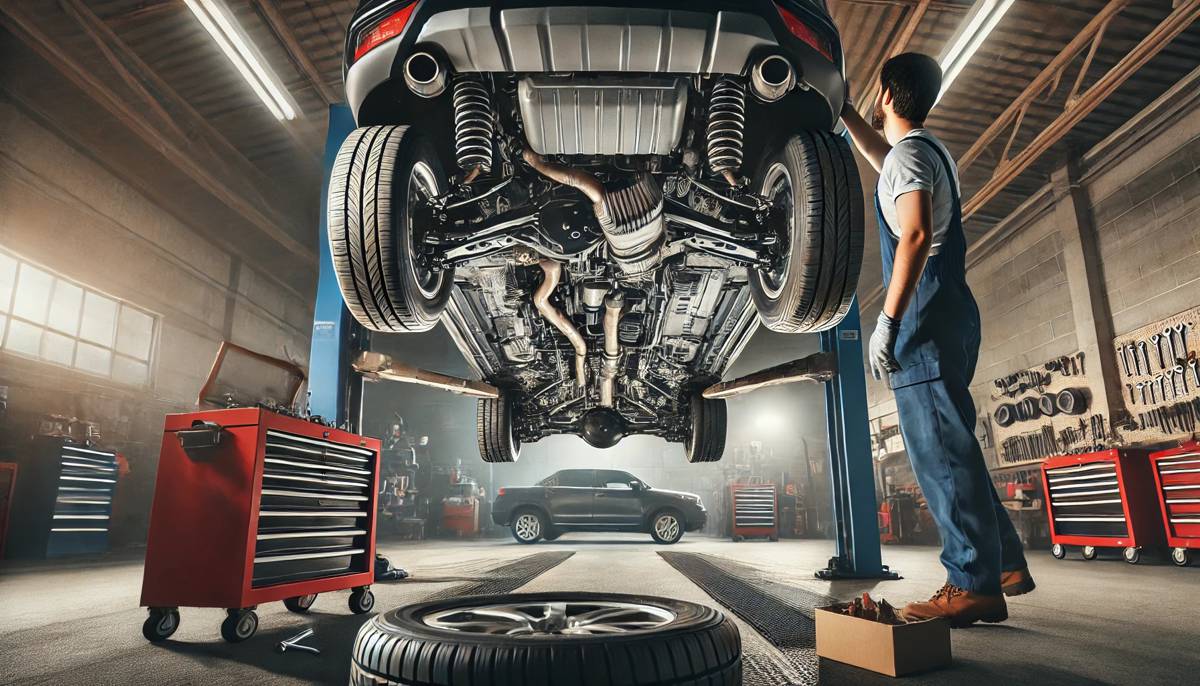

In automotive engineering and motorsports, precision is vital, and performance is paramount. Of all the means to have revolutionized the way we approach vehicle suspension testing and optimization, perhaps one of the most important tools has been the shock dyno.

This sophisticated tool makes quite a critical contribution to improving road safety and vehicle performance. Let’s look into how the Shock Dynos contribute to these critical aspects of automotive engineering.

Understanding Shock Dynos

A shock dyno, by meaning, is a dynamometer for the testing and analysis of shock absorbers with suspension systems. These devices work in the simulation mode, whereby they let the shock absorbers undertake different varieties of forces and speeds that yield valuable data to engineers and mechanics on how the suspension components work in different eventualities.

Key Features of Modern Shock Dynos

With features like the ones described, shock dynos like the LABA7 series have become indispensable in today’s automotive workshops and racing garages. These units can perform tests faster, simulate a speed of up to 1900 mm/s, which is required for very detailed performance analysis, and provide precision measurements because of advanced load cells and sensors for force measurement.

- Temperature Monitoring: Non-contacting temperature sensors for monitoring shock performance over variable thermal conditions.

- Data Logging: Advanced software package for collecting and analysing data in real-time.

Improving Road Safety

This road safety is improved with the help of a shock dyno, which helps ensure that the vehicle suspension system is performing properly.

- Faulty Shock Absorber Identification: The big advantage of the use of a shock dyno is the speed at which it can diagnose problems experienced with shock absorbers. Based on the graphical analysis of the Force vs. Displacement graph, technicians are able to ascertain information like:

- Blocked oil passages Broken shims Cavitation from the lack of gas pressure

- Early diagnosis of such factors prevents probable failures while on the road, greatly enhancing vehicle safety.

- Ensuring Consistent Performance: Comparison of left vs. right and front vs. rear dampers is enabled through the use of shock dynos. This ensures that the vehicle suspension is balanced for consistent handling and stability of the vehicle. An unbalanced performance of suspension creates unpredictable behaviour in a vehicle and may become challenging, especially when making an emergency manoeuvre or operating the vehicle in poor weather conditions.

- Quality Control and Warranty: Quality control through the application of shock dynos before releasing serviced or new shock absorbers enables every component to meet the requisite safety standards. This helps in:

- Elimination of potential errors

- Reduction in product failure likelihood

- Providing proof of proper functioning in case of warranty claims.

Vehicle Performance Optimization

Apart from safety, the use of shock dynos is one of the major ways through which vehicle performance optimization is done in the area of motorsports and high-performance applications.

- Precision Tuning: Showing shock performance through graphs lets the engineer know where informed adjustments need to be made. In racing, even minor changes in the setting up of the shock absorbers make a world of difference in vehicle handling and lap times.

- Customization for Specific Conditions: Shock dynos have the ability to simulate different kinds of road conditions or driving styles. This permits the suspension setting to be tailor-made for:

- Race-specific tracks Weather-specific

- Specific driver preferences

Comparison of Performance

Arguably, the most valuable feature of shock dynos in terms of performance optimization would be the ability to compare shocks. The technician could now do things like:

- Compare various brands or models of shock absorbers

- Investigate the effects of different suspension oils or gases

- Assess changes brought about by different valving configurations

In this data-driven approach, better choices and decisions translate into better performance with the vehicle.

Future of Suspension Technology

As automotive technologies evolve, so too does the role that shock dynos play in vehicle development and maintenance. Advanced features of electromagnetic shock dynos, better testing capability, integration of AI in predictive performance analytics, and virtual reality interfaces for ease in data interpretation further promise to make the technology even more capable. In essence, such developments will increase the application of safer and better-performing vehicles than ever.

The shock dyno has become an integral part of life in the automotive industry, bridging the gap between theoretical suspension design and real-world performance. Precise, instantaneous measurement of the real performance of the shock absorber, these machines enable the engineer or technician to optimize vehicle suspensions for safety and performance.

From the reliability of the daily commuter car, to fine-tuning high-performance racing vehicle suspensions, shock dynos play an integral part in the automotive ecosystem. As we continue to push the envelope in terms of vehicle performance and safety, tools such as shock dynos take centre stage in developing and maintaining advanced suspension systems.

Where milliseconds and millimetres often make all the difference, shock dynos stand in testimony to the precision and dedication needed to develop further better and safer performing vehicles for all.