Caterpillar and Trimble Powering the Future of Grade Control Solutions

The construction industry is in the midst of a technological revolution, and two powerhouses, Caterpillar and Trimble, are at the forefront of this change.

With a partnership spanning over two decades, these giants have recently extended their joint venture to drive further innovation in grade control technology. This renewed agreement promises to accelerate the adoption of grade control solutions across the construction sector, providing enhanced access to innovative technologies for contractors, operators, and project managers.

A Partnership Built on Innovation

When Caterpillar and Trimble first joined forces in 2002 to create Caterpillar Trimble Control Technologies (CTCT), the mission was clear: revolutionise the way construction projects are executed. Since then, they’ve introduced ground-breaking grade control technologies designed to enhance both jobsite safety and productivity. Grade control systems allow machines to perform at peak efficiency by automating tasks like digging, grading, and levelling, leading to faster completion times and reduced costs.

This latest extension of their joint venture aims to build on the success of CTCT, expanding distribution channels and introducing new, flexible platforms that make these advanced systems accessible to a wider array of customers. Whether you’re operating a Caterpillar machine or managing a mixed fleet, this partnership ensures greater integration and usability across the board.

Why Grade Control Matters

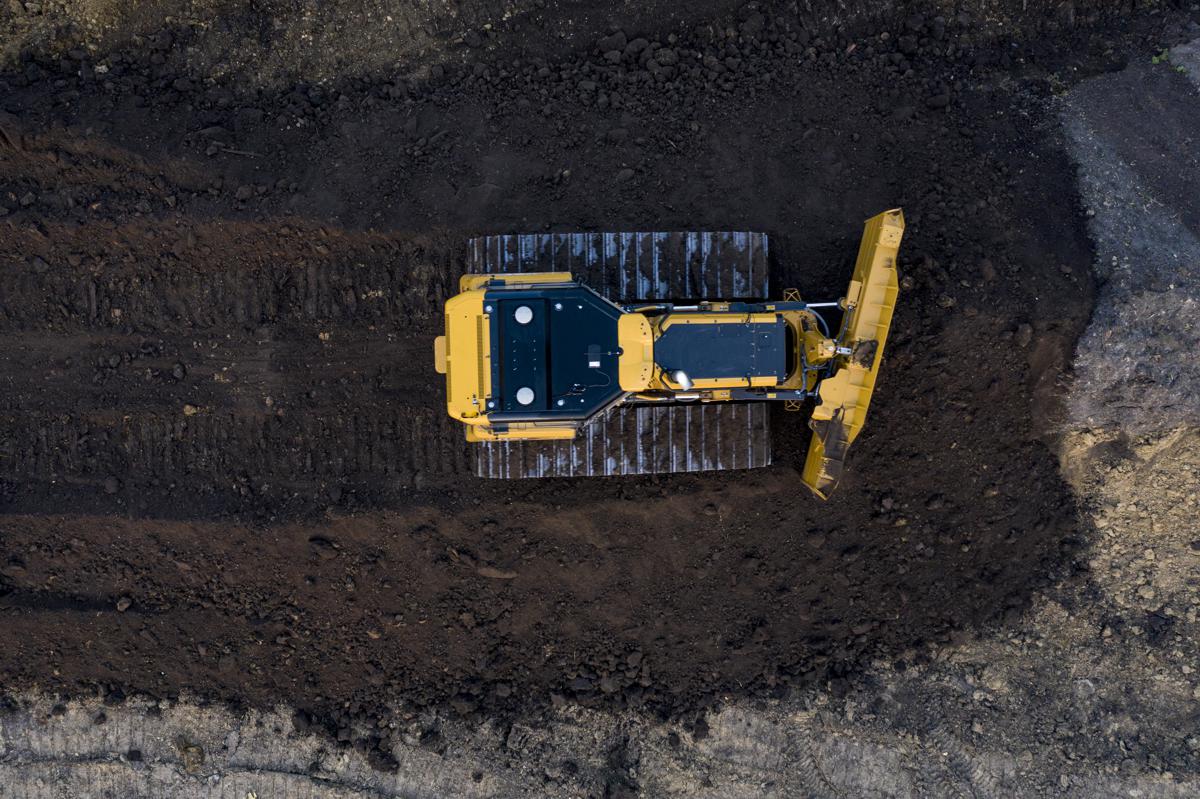

For those unfamiliar with grade control, think of it as a digital map guiding heavy machinery in real-time, ensuring that excavators, bulldozers, and graders cut, fill, and level the ground to exact specifications. This not only boosts accuracy but significantly reduces the margin of human error. Contractors and operators can ensure projects meet design specs more efficiently, while avoiding costly rework.

By automating much of the grading process, operators can achieve faster, more accurate results, making grade control a cornerstone of modern construction. However, the cost of these systems can be prohibitive for some, which is why Caterpillar and Trimble are focusing on increased accessibility and interoperability in their latest venture.

Enhanced Access for Caterpillar Customers

For Caterpillar customers, the extended partnership means more ways to access cutting-edge technology. From factory-installed systems to aftermarket solutions, there’s flexibility at every stage of the machine lifecycle.

Key offerings include:

- Factory-Fit Options: Customers can now get machines with grade control systems directly from the factory, cutting down on installation time and ensuring immediate productivity gains.

- Cat® Grade 3D Ready Options: Machines that aren’t factory-fitted with grade control tech can be upgraded later in their lifecycle, providing more flexibility for fleet owners.

- Expanded Aftermarket Solutions: Caterpillar is working closely with its extensive dealer network to offer aftermarket grade control options, as well as digital solutions for customers looking to retrofit their existing fleets.

Caterpillar’s global dealer network will play a key role in rolling out these offerings, making sure customers have the support and resources they need to adopt and integrate these advanced technologies seamlessly.

Trimble’s Commitment to a Digital Future

On Trimble’s side, the focus is on bringing more connectivity to the construction process. Through their Construction One™ suite of digital solutions, Trimble aims to streamline the user experience, offering integrated solutions for customers managing mixed fleets.

Their focus on interoperability means that users can benefit from Trimble’s solutions regardless of whether they’re using Caterpillar equipment or machinery from other manufacturers. This flexibility is a huge win for operators managing mixed fleets, ensuring that everyone can take advantage of the latest innovations in grade control technology.

Additionally, Trimble’s existing dealer network, particularly their SITECH® dealers, will continue to provide trusted, local support for contractors and fleet managers, ensuring they get the most out of their investments in grade control technology.

Driving the Future of Construction with Technology

The construction industry is on the brink of a new era of digital transformation, and Caterpillar and Trimble are perfectly positioned to lead the charge. Their combined expertise in heavy machinery and digital technologies ensures that the solutions they offer are both cutting-edge and practical.

Rob Painter, President and CEO of Trimble, notes that this partnership will “drive innovation in grade control technology to expand the industry opportunity with localised and differentiated solutions while improving technology interoperability.” By focusing on both the physical and digital aspects of construction, the partnership aims to close the gap between the office and the field, ensuring seamless communication and coordination throughout the project lifecycle.

Meanwhile, Tony Fassino, Caterpillar Construction Industries Group President, adds: “We are proud of what we’ve developed to help customers optimise their operations, including grade control. Today’s announcement is a continuation of this collaboration.” With both companies focusing on innovation, the future of construction looks bright, with increased efficiency, safety, and productivity on the horizon.

Looking Ahead

The extension of this joint venture is not just about maintaining the status quo. Both Caterpillar and Trimble are committed to pushing the boundaries of what’s possible, pursuing new opportunities in terms of product offerings and geographic reach. This includes developing solutions tailored to specific markets and needs, ensuring that their customers, regardless of location, can benefit from the latest technological advancements.

Additionally, there is a focus on sustainability and contributing to a reduced-carbon future. Both companies have committed to environmental goals that align with industry-wide shifts towards greener practices. For instance, Caterpillar’s innovative equipment, including their hybrid and electric machinery, will now have access to even more advanced grade control technologies, allowing for more efficient use of resources and less environmental impact on job sites.

As construction continues to evolve, the need for smarter, more efficient systems has never been greater. With the extended partnership between Caterpillar and Trimble, the industry is set to experience a new wave of innovation. These enhanced grade control solutions, now more accessible than ever, will empower contractors to deliver projects on time, on budget, and with unparalleled accuracy. As the two companies continue to push the boundaries of what’s possible, the future of construction looks more connected, efficient, and sustainable than ever before.

This renewed collaboration not only reaffirms their commitment to the industry but signals a bold step forward in the pursuit of construction excellence. Here’s to building a better, smarter world together.