Eaton’s Battery Configuration Switch brings flexibility to EV Charging

Electric vehicles (EVs) are transforming the transportation landscape, offering a cleaner, greener alternative to traditional petrol-powered cars. However, one of the main challenges facing the EV industry is the lack of consistency in charging infrastructure. Enter Eaton and its latest innovation—the Battery Configuration Switch (BCS)—which promises to solve a key issue for electric vehicle owners: the disparity between 400-volt and 800-volt charging systems.

Partnering with Munich Electrification, Eaton has developed an advanced power management solution designed to enhance the charging experience for EV users, making charging more flexible and accessible. Let’s delve into the significance of this partnership and how their cutting-edge technology can reshape the EV market.

Bridging the Charging Divide: Eaton’s Innovative Solution

The core of Eaton’s BCS innovation lies in its ability to enable seamless charging for 800-volt EVs at 400-volt chargers, a significant development given the current charging infrastructure. Mark Schneider, president of Eaton’s eMobility division, highlights the importance of this innovation:

“There are a lot of 800-volt vehicles in the market, but many charging stations can only supply 400-volt power. BCS provides charging flexibility to consumers who want access to an expanded network of DC chargers,” Schneider explained.

This advanced switch allows EVs equipped with 800-volt battery systems to effectively charge on more common 400-volt charging stations without sacrificing efficiency or performance. It’s a major leap in making EV ownership more practical, as the current charging infrastructure lags behind the rapid advancements in EV technology.

Streamlining Battery Technology

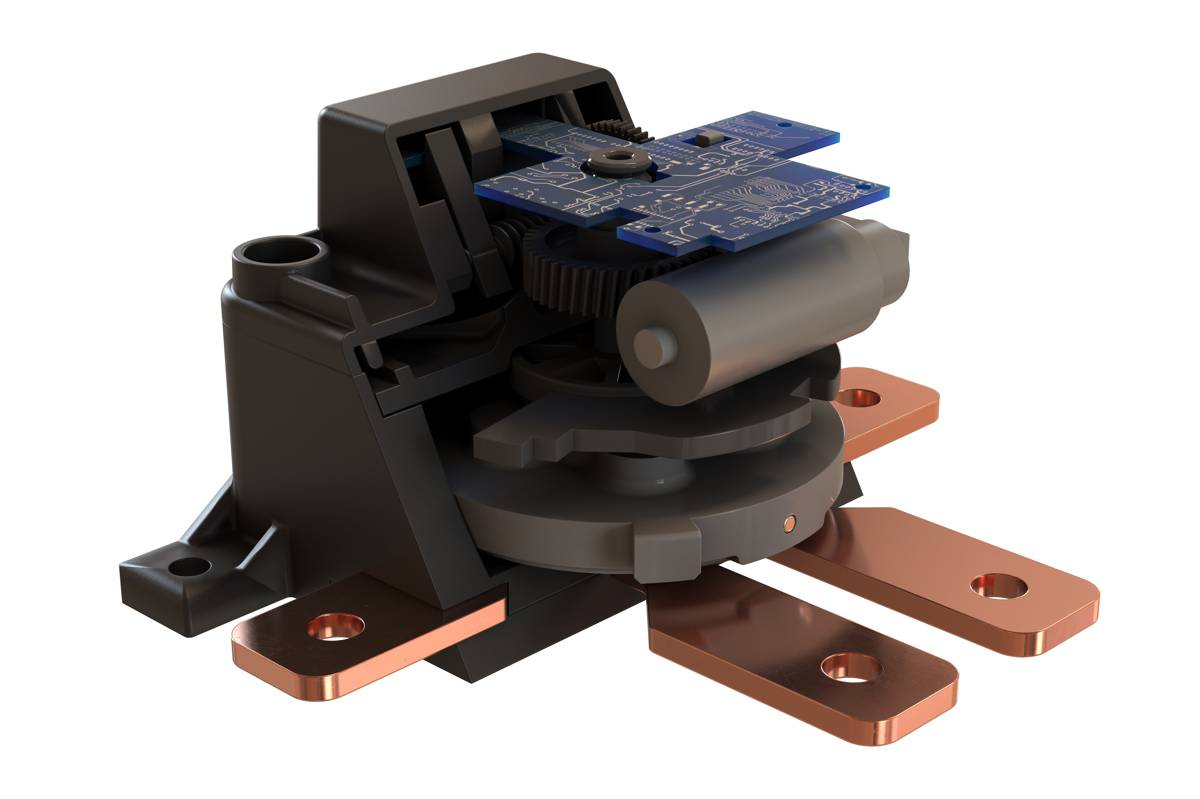

One of the standout features of Eaton’s Battery Configuration Switch is its ability to simplify the design of EV battery systems. Traditionally, battery disconnect units (BDUs) require numerous components to manage the switching and safety functions in electric vehicles. Eaton’s BCS can reduce the number of components in the BDU by up to 12, making it a streamlined and space-saving solution.

This reduction in complexity not only simplifies the packaging and assembly of the battery system but also enhances performance. By cutting down the number of contact points that traditional contactors rely on, the BCS minimises contact resistance, which in turn boosts the overall efficiency of the vehicle. In the highly competitive EV market, every bit of efficiency gained can have a considerable impact on the vehicle’s range and charging speed.

Enhanced Safety in Electric Vehicles

When it comes to EVs, safety is a critical concern. EV batteries are powerful and complex, and any fault in the system can have catastrophic consequences. Eaton’s BCS incorporates a mechanical interlock that prevents short circuits in the event of a crash, software malfunction, or contactor failure. This built-in safety mechanism ensures that the battery remains protected and the vehicle operates safely, even in unpredictable scenarios.

The BCS is also bi-stable, meaning that it doesn’t require a constant electrical current to maintain its position, unlike traditional contactors. This feature reduces energy consumption during normal operations, further boosting the overall efficiency of the vehicle. Moreover, in case of low-voltage faults, the BCS can maintain a safe condition, offering a robust solution for a variety of potential failure modes.

As Uwe Wiedemann, managing director of Munich Electrification, points out: “Munich Electrification’s legacy of innovation in the EV battery industry combined with Eaton’s expertise in electrical switching and automotive manufacturing is helping us to solve our customers’ biggest challenges together.”

Addressing the Industry’s Growing Pains

The partnership between Eaton and Munich Electrification couldn’t have come at a better time. The EV industry is expanding rapidly, but with growth comes the inevitable challenges. Charging infrastructure varies widely across regions, with many stations unable to support the higher 800-volt systems becoming standard in new EV models.

By offering a solution that bridges this gap, Eaton’s BCS is positioned to become a key component in the global EV ecosystem. Drivers of 800-volt vehicles will no longer be limited to finding high-voltage charging stations, making long-distance travel and day-to-day driving more convenient. The result? A more seamless and accessible experience for EV owners.

The Power of Partnerships

What makes this innovation even more significant is the collaboration behind it. Eaton, a leader in power management, teamed up with Munich Electrification, a company renowned for its state-of-the-art battery management systems. Together, they’ve combined their expertise to bring a much-needed solution to the EV market.

Munich Electrification has deep roots in the automotive industry, with a team of passionate professionals from 24 nations who’ve worked with well-known car manufacturers. Their experience, combined with Eaton’s global reach and technological capabilities, has resulted in a product that not only addresses current challenges but also sets the stage for future advancements in EV technology.

Looking Towards a Sustainable Future

Eaton’s commitment to sustainability and improving the quality of life for people around the world underpins their work. By developing products that help accelerate the transition to renewable energy sources, Eaton is tackling some of the world’s most urgent power management challenges. The BCS is a perfect example of this commitment in action.

From data centres to aerospace, Eaton’s innovations span multiple industries, but their focus on the mobility market stands out as they seek to build a more sustainable future for transportation. As electrification and digitalisation continue to grow, solutions like the BCS will play a crucial role in reshaping how we power and drive our vehicles.

What This Means for the Future of EV Charging

Eaton’s Battery Configuration Switch is more than just another EV component. It represents a significant step forward in making electric vehicles more practical and user-friendly, especially in an industry where technology often outpaces infrastructure. With the ability to charge 800-volt vehicles at 400-volt stations, the BCS offers the kind of flexibility that could encourage more drivers to make the switch to electric.

By simplifying battery design, improving safety, and enhancing efficiency, Eaton and Munich Electrification have created a solution that addresses some of the most pressing challenges in the EV market. As more manufacturers adopt this technology, the charging experience for EV owners is set to become more seamless, making electric driving more accessible to a wider audience.

Driving the Future

Eaton and Munich Electrification’s collaborative approach to solving real-world challenges in the EV industry is a testament to the power of partnerships. Their BCS technology is poised to revolutionise how electric vehicles are charged, making EV ownership easier and more convenient for everyone.

As the world continues its shift toward sustainable energy, innovations like Eaton’s Battery Configuration Switch will undoubtedly play a pivotal role in shaping the future of mobility. With a focus on reducing complexity, improving safety, and offering flexibility, Eaton is paving the way for a future where electric vehicles are the norm, not the exception.