3D Printing Ultra-Strong Stainless Steel

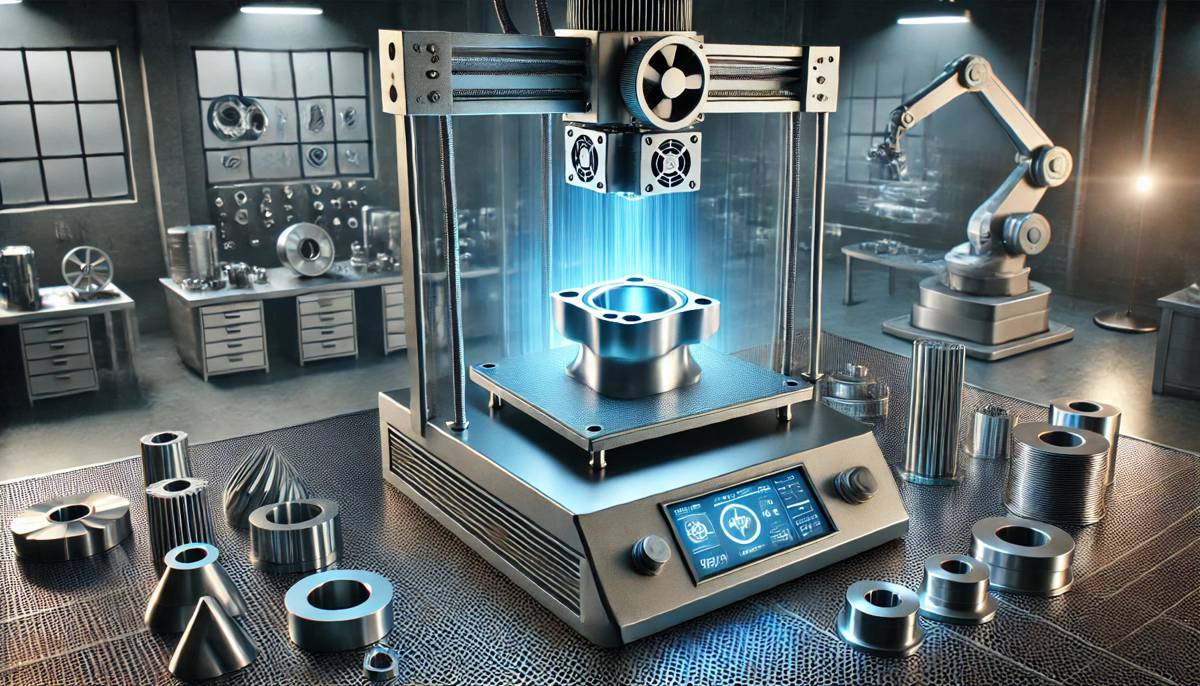

In an impressive breakthrough, researchers have successfully 3D printed one of the world’s toughest stainless steels—17-4 PH—offering significant advancements for industries ranging from aviation to medical devices.

Traditionally, additive manufacturing, or 3D printing, has faced challenges when working with metals like 17-4 PH due to rapid temperature changes that compromise its structural integrity. By overcoming these barriers, scientists have paved the way for more versatile, cost-effective production options for highly durable materials.

17-4 PH Stainless Steel

Known for its exceptional strength and corrosion resistance, 17-4 PH stainless steel is critical in applications requiring high durability, such as marine vessels, aircraft, and industrial machinery. The advent of 3D printing this material could enable manufacturers to rapidly produce complex, customised parts without the traditional constraints of casting and machining.

But how did they achieve it? Researchers relied on a powerful tool: bright X-ray beams. By monitoring the rapid structural changes occurring during the heating and cooling processes in real time, they adjusted the chemical composition, achieving a more resilient final product. This scientific leap could redefine what’s possible in the world of industrial 3D printing.

Overcoming the Hurdles in Metal 3D Printing

3D printing metal alloys has been notoriously difficult due to the rapid temperature shifts involved in the process. These temperature fluctuations, spurred by laser heating in 3D printers, alter the arrangement of atoms in metals, reducing the toughness required for high-performance alloys like 17-4 PH stainless steel. The challenge, therefore, lay in stabilising these changes and achieving consistent results.

To tackle this, scientists developed an innovative method to track and adjust for these shifts in real time. Utilising high-energy X-rays at the Department of Energy’s Advanced Photon Source (APS) at Argonne National Laboratory, researchers were able to capture millisecond-by-millisecond images, allowing them to observe and adjust the atomic structure of the material as it was printed. This approach marks a new era in understanding the science of metal 3D printing and paves the way for further breakthroughs.

X-Rays Made the Difference

Unlike traditional inspection techniques, high-energy X-ray diffraction offers the precision and speed needed to observe the quick temperature-induced changes in metal alloys during 3D printing.

This technique enables scientists to map out how process parameters like laser intensity and cooling rates impact the atomic arrangement. By correlating these parameters with structural changes, they managed to finetune the alloy’s composition to withstand the demands of 3D printing, making the end product as robust as traditionally manufactured 17-4 PH stainless steel.

Implications for Broader Manufacturing

The success in printing 17-4 PH stainless steel doesn’t just benefit those specific industries; it opens doors for other materials traditionally challenging to print. By utilising the X-ray mapping technique, manufacturers might soon be able to print a wide array of alloys and advanced materials, each with unique properties tailored to demanding environments.

This breakthrough in 3D printing technology offers potential cost savings and production flexibility for industries reliant on high-strength materials. For instance, aerospace and automotive manufacturers could leverage this method to print complex metal parts, reduce material waste, and enhance production speed without sacrificing quality.

Potential Applications Across Key Industries:

- Aerospace and Defence: Lightweight, high-strength components produced on demand, cutting production times and costs.

- Medical Device Manufacturing: Customised surgical tools and implants created in sterile environments directly from digital designs.

- Marine and Industrial Machinery: Corrosion-resistant parts that can withstand harsh environments, improving equipment longevity and safety.

Each of these sectors, faced with their own manufacturing challenges, stands to gain from this advancement in producing durable parts swiftly and efficiently.

The Science Behind Printing 17-4 PH Stainless Steel

Creating a high-quality 3D printed material requires close control over its crystal structure. For 17-4 PH stainless steel, this means aligning tiny structural anomalies known as nanoprecipitates, which greatly influence the metal’s final strength. Using small-angle X-ray scattering at APS, researchers could analyse these nanoprecipitates, enabling them to enhance the final product’s resilience. The results speak for themselves: a 3D printed stainless steel part that rivals or even surpasses conventionally produced ones in durability and consistency.

By mapping the correlation between process parameters and changes in the crystal structure, scientists created a blueprint for optimising the printing process. The data collected during this experiment allowed them to develop a robust method that other researchers and manufacturers can replicate for various applications. This novel approach not only elevates the quality of 3D printed metal components but also significantly reduces the trial-and-error phase, which is both costly and time-consuming in traditional manufacturing methods.

Transformative Potential for Additive Manufacturing

One of the most promising aspects of this development is the potential for cost savings and streamlined manufacturing. Traditional metalworking techniques often involve excessive waste and significant energy demands. With 3D printing, manufacturers can optimise material use and only produce what’s necessary, aligning with sustainability goals across many industries.

Moreover, additive manufacturing allows for greater design freedom. Complex shapes that were once impossible to create with casting or machining can now be made layer by layer, reducing the need for assembly and enhancing structural integrity. For construction, aerospace, and beyond, this opens the door to novel design possibilities, enabling engineers to push the boundaries of innovation.

With the success of 3D printing 17-4 PH stainless steel, researchers are setting their sights on other materials that could benefit from similar processes. From titanium alloys used in aviation to copper alloys needed in electronics, the technology promises to make additive manufacturing a staple in industries requiring complex, high-performance components. As research progresses, the knowledge gained here could soon be applied to other sectors, further bridging the gap between design freedom and material resilience.

A Transformative Era for Manufacturing

In conclusion, the breakthrough in 3D printing 17-4 PH stainless steel signals a pivotal shift for manufacturing as we know it. By pushing the boundaries of what’s achievable in additive manufacturing, researchers have not only expanded the possibilities of metal 3D printing but also laid the groundwork for future advancements in material science. This achievement underscores the potential of 3D printing to redefine production, offering industries the flexibility to innovate like never before.

With applications that span defence, aerospace, medical devices, and beyond, this is just the tip of the iceberg for additive manufacturing. The door to new innovations is open, and as manufacturers start to adopt these methods, the future of industrial production looks stronger, more flexible, and incredibly promising.