Toyoda Gosei Unveils Smartphone-Based Truck Load Calculation System

Efficient logistics are the backbone of modern industries, and Toyoda Gosei Co., Ltd. has taken a giant leap forward in transport optimisation. Leveraging cutting-edge 3D sensing technology, the company has unveiled a smartphone-based load calculation system that could revolutionise truck allocation and routing.

With its innovative approach, Toyoda Gosei not only enhances transport efficiency but also paves the way for more sustainable logistics operations.

Rethinking Logistics with 3D Smartphone Sensors

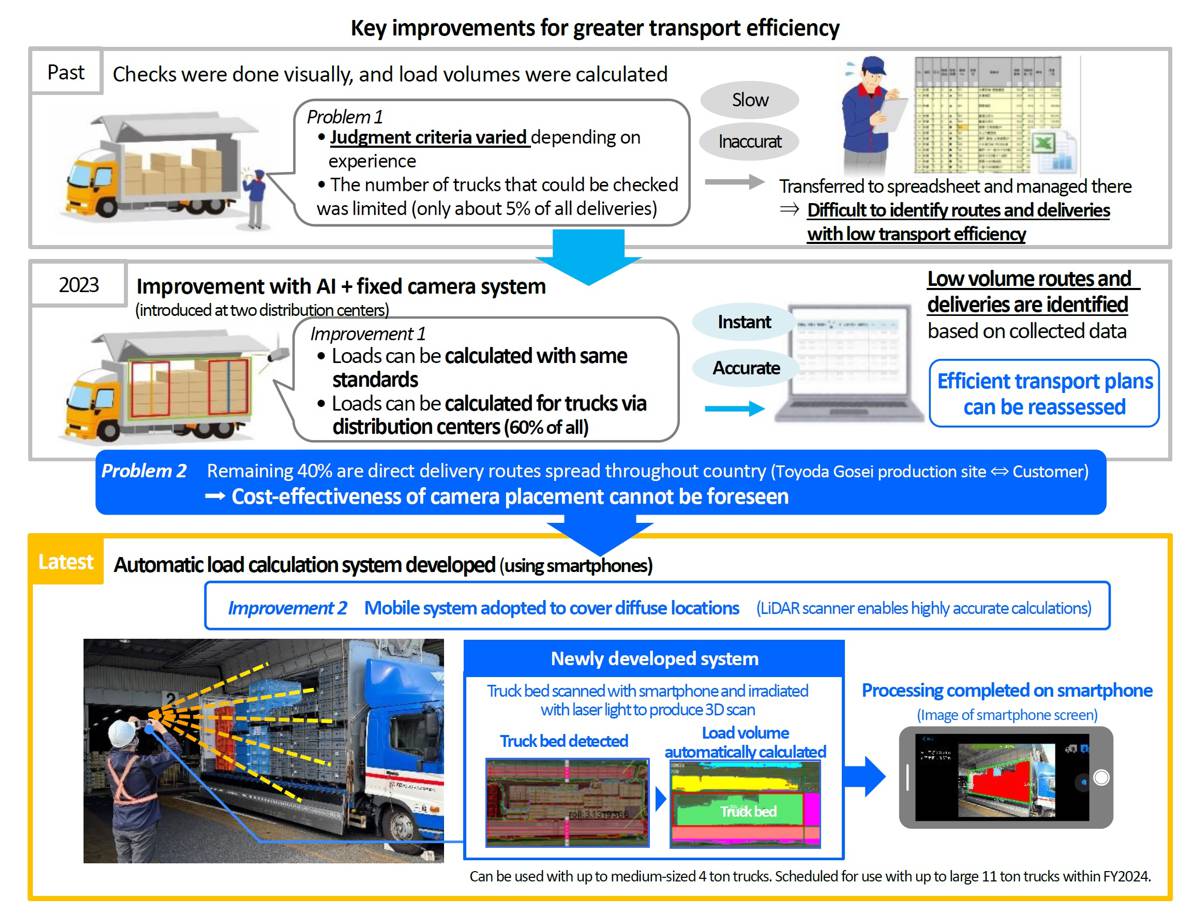

In a world where time is money, the ability to calculate truck load capacity quickly and accurately can save businesses millions. Traditionally, load volumes were assessed visually by on-ground personnel, leading to variability in judgement and limitations on the number of trucks that could be evaluated. This labour-intensive process was ripe for disruption.

Enter Toyoda Gosei’s new system, which uses 3D sensing technology embedded in smartphones to measure truck loads with pinpoint accuracy. The innovation lies in the integration of Light Detection and Ranging (LiDAR) technology—a method that determines object distance and shape based on laser light reflection.

This mobile solution enables quick and precise load calculations without the constraints of fixed locations. It marks a shift from manual operations to a streamlined, technology-driven process that saves time, reduces errors, and ensures better use of transport resources.

Fixed Camera Systems Lead the Way

Before the advent of the smartphone-based system, Toyoda Gosei had already implemented AI-powered load calculation using fixed cameras. Deployed at two of the company’s largest distribution hubs—the Miyoshi Distribution Center and the Ichinomiya Distribution Center of TG Logistics—this system operates 24/7, eliminating human inconsistencies in assessing truck capacities.

By automating load evaluations, these centres, which handle 60% of the company’s transport operations, significantly increased their efficiency. With consistent optimisation of truck usage and route planning, the AI-based system laid the groundwork for the broader application of these technologies.

However, while fixed cameras revolutionised large-scale operations, they were confined to specific locations. The next logical step was mobility—an area where smartphones shine.

Smartphone 3D Sensing

Recognising the need for a more flexible solution, Toyoda Gosei expanded its innovations to include a smartphone-based 3D sensing system. Unlike fixed installations, this mobile technology empowers users to conduct load evaluations anywhere. It’s particularly useful for routes outside the centralised distribution hubs, where transport volume accounts for the remaining 40% of the company’s operations.

The LiDAR scanner embedded in modern smartphones ensures calculations remain highly accurate, bridging the gap between portability and precision. With this system, Toyoda Gosei aims to roll out efficiency improvements across direct delivery routes and smaller production locations, creating a more cohesive logistics network.

The Science Behind LiDAR

The core of this technological leap lies in LiDAR—an advanced sensing technology that measures distances and object dimensions by analysing laser light reflections. While commonly associated with autonomous vehicles and robotics, LiDAR’s application in logistics is transformative.

By integrating this technology into smartphones, Toyoda Gosei effectively miniaturised the power of advanced sensing. This move not only makes the system accessible but also positions the company at the forefront of digital transformation in logistics.

Benefits Beyond Numbers

The implications of Toyoda Gosei’s innovation stretch beyond operational efficiency. By optimising truck loads and routes, the company reduces fuel consumption and greenhouse gas emissions, contributing to more sustainable transport practices.

Moreover, this technology-driven approach minimises human error and ensures consistency in logistics operations. The result? Improved reliability for automaker clients, cost savings for the company, and a smaller environmental footprint.

What’s Next

As the global logistics industry races toward digitisation, Toyoda Gosei’s advancements position it as a leader in smart transport solutions. The company’s focus now is on scaling this smartphone-based system across all its operations and exploring further innovations.

By marrying LiDAR technology with artificial intelligence, the potential for real-time route optimisation and predictive analytics is immense. Additionally, as smartphones become even more powerful, the applications of this system could extend to other industries, from retail to e-commerce.

A Vision for the Future

This innovative approach underscores a broader trend in logistics—embracing technology to solve age-old challenges. By combining the precision of AI, the versatility of smartphones, and the power of LiDAR, the company demonstrates that the future of transport lies in smart, connected systems.

This is just the beginning. As technology evolves, the possibilities for improving logistics efficiency are limitless. Toyoda Gosei’s journey serves as a blueprint for how industries can innovate to achieve sustainability, precision, and operational excellence.