Redefining Construction Safety With Real-Time Telematics

The construction industry has long grappled with balancing efficiency and safety, often relying on time-consuming manual processes. But with the advent of cutting-edge technologies, those days are becoming a distant memory.

PVS Data (Plant and Vehicle Services Ltd) and Xwatch Safety Solutions, a Hexagon Group company, have joined forces to revolutionise fleet management and site safety. Their innovative telematics platform, powered by the D2 unit, is setting a new standard for construction operations.

Let’s dive into how this game-changing collaboration is reshaping construction safety, optimising site efficiency, and laying the groundwork for a smarter, safer industry.

Transforming Safety Standards with Real-Time Insights

Gone are the days of manual checks for machine hours, fuel usage, and load capacities. PVS Data’s state-of-the-art D2 unit now enables access to over 300 real-time data parameters. From live engine performance to precise geolocation using the What3Words (w3w) app, site managers can monitor operations with unprecedented clarity.

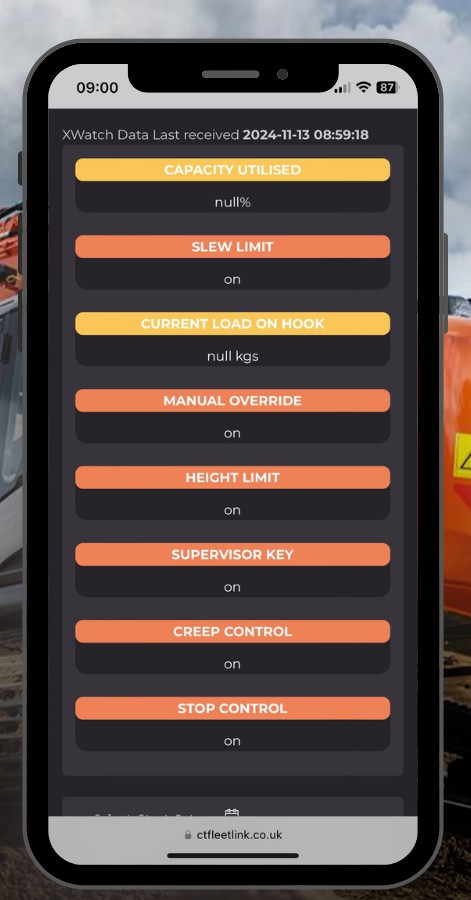

But it doesn’t stop there. By integrating with Xwatch Safety Solutions, the system offers unparalleled safety metrics, including height, slew, and Rated Capacity Indicator (RCI) data. Operators can set and monitor these parameters directly from their cab, providing a level of control that enhances both safety and productivity.

Dan Leaney, Sales Director at Xwatch Safety Solutions, explained: “The telematics system for the D2 units from PVS, branded as XW-Insite by Xwatch, represents our most advanced safety and telematics solution to date. This innovation is designed to prevent accidents, reduce downtime, and enable smarter, data-driven decisions.”

This seamless integration allows managers to remotely oversee critical safety data, ensuring machines and operators work harmoniously and efficiently.

Advanced Telematics and Elevating Fleet Management

The collaboration between PVS Data and Xwatch brings a unique, cloud-based platform that works seamlessly across mixed-brand fleets, including JCB, Sany, Hitachi, and Takeuchi. With real-time data at their fingertips, managers can:

- Monitor height and slew settings.

- Check the exact weight on hooks.

- Confirm the status of stop and creep controls.

- Evaluate overall capacity utilisation.

This is complemented by comprehensive machine data, including fuel usage, engine diagnostics, and idle vs productive hours. Such transparency not only enhances safety but also optimises operational efficiency, reduces downtime, and extends machinery lifespans.

Scott McCabe, Owner and Director of PVS Data, highlighted the partnership’s potential: “Heightened safety on-site has been at the heart of the industry for decades. Our platform delivers a single source of truth for fleet health and safety, paving the way for smarter, safer construction sites.”

Hitachi’s Role in Driving Connectivity

Leading the charge in connected construction technology is Hitachi Construction Machinery UK (HCMUK). By integrating PVS Data’s platform into their operations, they’ve introduced CTFleet Link®, a custom-branded telematics solution that provides clients with a unified view of their fleet.

Stephen Creaser, Director of Product Support at HCMUK, shared his enthusiasm: “At Hitachi UK, we’ve always been proud to champion innovation in the industry. PVS and Xwatch Safety Solutions are a natural fit for our mission to connect fleets and improve safety standards. The ability to monitor machine status and operator controls in real-time is transforming how we manage construction sites.”

The benefits are tangible: safer operations, reduced costs, and a connected ecosystem that fosters informed decision-making.

Efficiency Meets Sustainability

Combining advanced safety data with real-time operational insights creates a powerful tool for construction companies. Beyond improving safety, the platform helps businesses:

- Cut carbon emissions through efficient fuel management.

- Reduce machinery wear and tear.

- Minimise unplanned downtime with predictive maintenance.

- Encourage data-driven decision-making for long-term growth.

These innovations also support broader sustainability goals. By optimising machine usage and reducing unnecessary idling, companies can contribute to a greener future while saving on operational costs.

Scaling Innovation Across the Industry

The PVS-Xwatch partnership is just the beginning. Current trials with a leading plant hire firm, a tier-one contractor, and PVS’s own fleet hint at the transformative impact this technology could have on the industry. As more companies adopt these systems, we’re likely to see a ripple effect of safer, more efficient construction sites worldwide.

Dan Leaney remains optimistic: “We’re proud to collaborate with PVS to lead the industry in making construction sites safer and more efficient. As these trials progress, we look forward to delivering even more meaningful insights.”

Smarter, Safer Construction

This partnership is more than just a technical achievement; it’s a blueprint for the future. By leveraging real-time data, cloud-based platforms, and advanced safety metrics, PVS Data and Xwatch Safety Solutions are redefining what’s possible on construction sites.

A safer site is a more connected site—where managers, operators, and machines work together seamlessly. With eyes on every machine and data driving every decision, the construction industry is poised for a safer, smarter, and more sustainable future.