Metso Secures €70m Contract for Ground-breaking Gold Plant in Türkiye

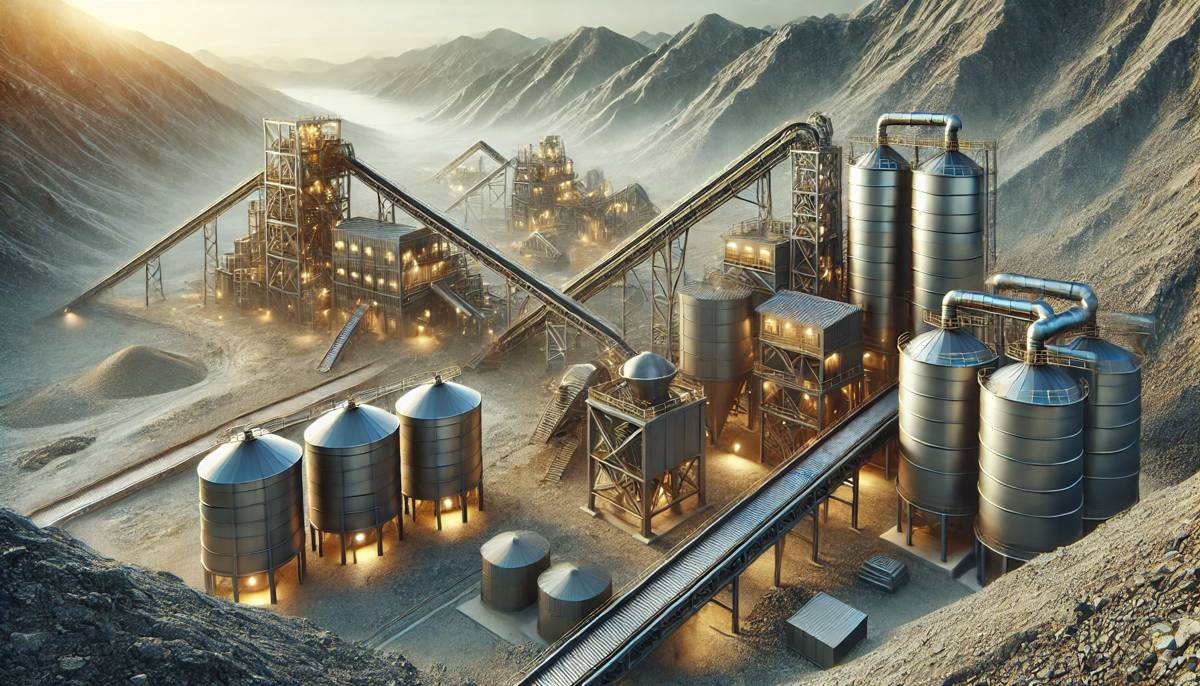

Metso, a global leader in sustainable technologies, has been awarded a significant contract worth approximately €70 million to deliver a complete gold ore processing plant for Gübretaş Maden Yatırımları A.Ş.

This collaboration marks Phase II of the Soğüt project, located in the Bilecik province of Türkiye, and is poised to reshape the Turkish mining landscape.

The agreement, announced on 12 December 2024, underscores the critical role of cutting-edge technology in the mining industry. Equipment orders under this deal will be booked under Metso’s Minerals segment, with contract finalisation anticipated by early 2025. The move not only highlights Metso’s position as a trusted partner in the sector but also promises significant economic and operational benefits for Türkiye.

Cutting-Edge Technology at the Core of the Soğüt Project

The Soğüt gold plant will be a showcase of advanced mining technology. Metso will supply an extensive range of equipment, including:

- Nordwheeler™ jaw crushing unit for robust and efficient ore crushing.

- Select™ SAG and ball mills to ensure optimal grinding processes.

- TankCell® flotation cells of varying sizes for enhanced mineral recovery.

- HRT High Rate Thickening units and Larox® PF pressure filters to support dewatering and filtration processes.

- Slurry pumps and specialised gold room equipment for efficient handling and processing.

- Analytical tools such as the Courier® 8X SL analyser and PSI® particle size analysers, alongside samplers and the Proscon automation system, to ensure precise monitoring and control.

Moreover, Metso’s contribution includes full engineering services, installation advisory, commissioning, and training, ensuring a seamless integration of these advanced systems.

Why Metso Was the Preferred Choice

Gübretaş Maden Yatırımları A.Ş. General Manager Halit Semih Demircan emphasised the strategic importance of selecting Metso. “This greenfield project will have a major contribution to the Turkish mining business and economy. It was important for our team to select the best technology to ensure top-class performance. We believe that Metso’s proven gold processing technologies will provide this. An additional criterion for us was Metso’s service capabilities and their experienced local team,” Demircan stated.

Echoing this sentiment, Mert Katkay, Metso’s Regional Minerals Sales Director, highlighted the collaborative approach taken to develop an optimised flowsheet for the project. “Basic engineering for the plant and gold pressure oxidation has already been completed, and we are looking forward to continuing in phase II with equipment deliveries, together with the Gübretaş Maden Yatırımları A.Ş. team,” Katkay explained.

Metso’s Comprehensive Gold Processing Solutions

Metso’s portfolio spans the full gold value chain, addressing both free-milling and refractory gold ores. Their services include:

- Ore sorting and comminution: High-performance crushing and grinding equipment.

- Flotation and refractory ore pre-treatment: Bio-oxidation, pressure oxidation, and roasting technologies.

- Gold recovery processes: Advanced cyanide leaching and extraction solutions.

- Tailings and effluent management: Sustainable approaches to waste treatment and water recycling.

- Automation and analytics: State-of-the-art monitoring tools for real-time operational efficiency.

This holistic approach ensures Metso’s clients achieve optimal productivity while reducing environmental impacts—a hallmark of their sustainability-driven ethos.

Supporting Economic Growth in Türkiye

The Soğüt project promises to bolster Türkiye’s mining sector, contributing to both local job creation and national economic growth. By leveraging Metso’s expertise, the facility aims to set new standards in efficiency and sustainability for the region.

Metso’s collaboration with Gübretaş also highlights the increasing importance of advanced technologies in transforming the mining sector. As global demand for gold continues to rise, investments in high-performance processing solutions are crucial to meeting industry needs while adhering to environmental standards.

A Partner for Positive Change

Headquartered in Espoo, Finland, Metso has long been at the forefront of sustainable innovation. With a global workforce of over 17,000 across nearly 50 countries, the company achieved impressive sales of €5.4 billion in 2023.

Metso’s commitment to improving energy and water efficiency, boosting productivity, and minimising environmental risks positions them as a trusted partner for transformative projects like Soğüt.

A Bright Future for Turkish Mining

This landmark partnership between Metso and Gübretaş underscores the potential of innovative technologies to revolutionise mining practices. With Phase II of the Soğüt project on the horizon, the stage is set for Türkiye to solidify its position as a leader in sustainable mining.

By embracing advanced solutions and fostering collaborations with industry leaders, Türkiye’s mining sector is well-poised to meet future challenges head-on. This project not only represents a milestone for Gübretaş and Metso but also serves as a beacon of progress for the global mining community.