Concrete Milling with GENERATION C² Round-Shank Picks

Concrete milling has undergone a dramatic transformation, thanks to innovations from the Wirtgen Group.

Among these, the GENERATION C² round-shank picks, paired with the ECO Cutter milling drums, have emerged as a game-changer. Offering unmatched efficiency, durability, and sustainability, this combination is redefining how construction professionals tackle the challenges of concrete pavement rehabilitation.

Concrete Milling

When it comes to road construction, concrete has earned its reputation as a resilient and durable material. However, even the toughest concrete pavements can degrade over time, requiring rehabilitation. Traditional repair methods, such as breaking, rubblisation, or excavation, often come with a hefty price tag—not to mention their time-intensive processes.

Concrete milling has stepped in as a cost-effective and environmentally friendly alternative. By removing damaged concrete in a precise and efficient manner, this technique conserves resources and reduces the environmental footprint. Enter the GENERATION C² round-shank picks—an innovation purpose-built for concrete milling, delivering exceptional results while minimising wear and tear on machinery.

ECO Cutter Milling Drums and GENERATION C² Picks

Concrete is notorious for its hardness, presenting a formidable challenge to traditional cutting tools and machines. The Wirtgen ECO Cutter milling drums, equipped with GENERATION C² round-shank picks, tackle this challenge head-on.

- Optimised Tool Spacing: Fewer round-shank picks on the drum increase the force applied by each pick, accelerating the machine’s advance rate and enhancing productivity.

- Enhanced Area Performance: The combination ensures the removal of extensive concrete surfaces quickly and efficiently, saving both time and money.

The Science Behind GENERATION C²

The secret to the GENERATION C² round-shank picks lies in their meticulous engineering. These picks don’t just cut concrete; they redefine how cutting is done, boasting a host of features that set them apart:

- Solid Steel Body Geometry: Enhances material removal efficiency.

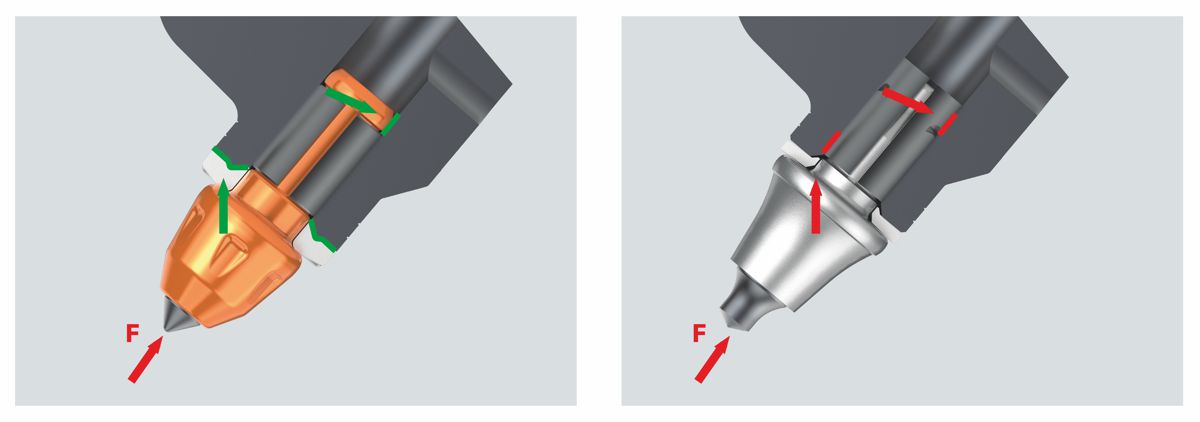

- Optimised Pick Centring: Concentrates milling forces at the top of the holder, reducing stress on the clamping sleeve.

- Short Clamping Sleeve Design: Minimises mechanical loading, ensuring consistent clamping force throughout its lifespan.

- Innovative Wear Plate: The grooved profile and centring function reduce wear on both the picks and the toolholders.

- Enhanced Shank Geometry: Increases resistance to fracturing, extending service life.

These features culminate in better cutting performance, longer service life, and reduced operational costs—a trifecta of benefits for construction professionals.

Cost Efficiency Meets Sustainability

One of the standout advantages of the GENERATION C² picks is their excellent price-performance ratio. By significantly reducing operating costs and extending the lifespan of the tools, these picks help construction firms optimise budgets without compromising on quality.

Moreover, the sustainable aspects of this technology are worth noting. By minimising material waste and reducing the need for frequent tool replacements, the GENERATION C² round-shank picks contribute to conservation efforts, aligning with the industry’s growing emphasis on green practices.

Real-World Success Stories

Construction professionals using the Wirtgen Group’s milling technology have already reported notable successes. Projects that once required extended timelines and considerable resources are now completed more efficiently and economically.

Through collaboration with Wirtgen, these users have continuously refined the milling process, unlocking new levels of profitability and performance.

Why It Matters

The construction industry is under increasing pressure to deliver projects faster, cheaper, and with less environmental impact. Innovations like the GENERATION C² picks address all three goals, offering a viable solution for today’s challenges.

By reducing downtime, enhancing cutting efficiency, and lowering costs, these tools empower companies to achieve more with less—without compromising quality or sustainability.

A Bright Future for Concrete Milling

Looking ahead, the combination of Wirtgen ECO Cutter milling drums and GENERATION C² round-shank picks promises to remain a cornerstone of modern concrete rehabilitation techniques.

With their unparalleled durability, efficiency, and environmental benefits, they represent a future where construction is not only cost-effective but also eco-friendly.