Sleipner Dollies Revolutionise Worker Safety in Mining Operations

A ground-breaking study by the Finnish Institute of Occupational Health has brought to light the significant health benefits of using Sleipner dollies to reduce whole-body vibration exposure for excavator operators.

Conducted in May 2023 at a Finnish mine, the study highlights how these innovative transport solutions can mitigate health risks while enhancing worker comfort and efficiency.

Whole-body vibration is a well-documented occupational hazard, particularly in industries like mining and construction. Frequent exposure can lead to long-term health issues, including musculoskeletal disorders and chronic pain. This study provides concrete evidence that Sleipner dollies represent a game-changing solution to this pervasive problem.

Vibration Testing – A Comparative Analysis

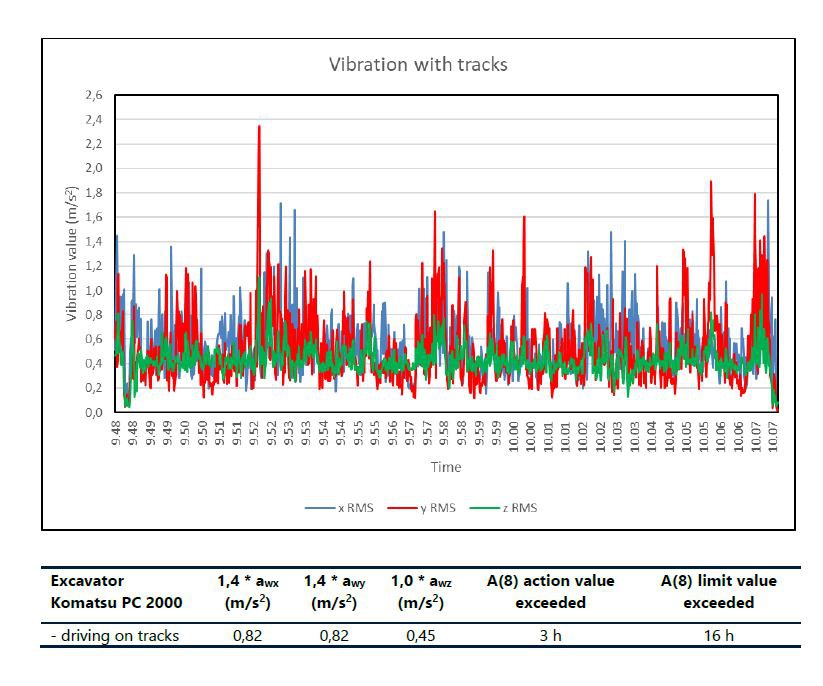

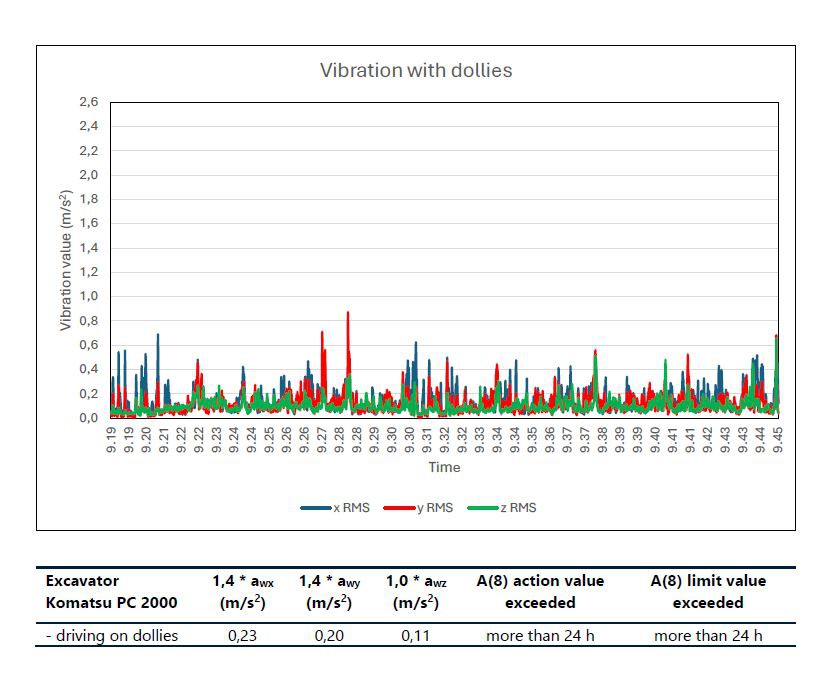

The research focused on measuring vibration levels experienced by excavator operators when moving equipment within a mining site. Two scenarios were tested: driving a Komatsu PC 2000 excavator on its tracks and transporting it on Sleipner E190 Series dollies. A Komatsu 830E haul truck was used to pull the excavator during the dolly test.

Measurements spanned 26 minutes for the dolly transport and 20 minutes for track driving, with both the operator and the testing specialist remaining inside the excavator cab. The tests were carried out on a gravel road in optimal conditions, ensuring accurate and reliable results.

Key findings include:

- Driving on Tracks: Operators experienced an average vibration acceleration of 0.82 m/s² in the forward and lateral directions. Exposure at this level surpasses the action value threshold (0.5 m/s²) within just three hours of operation, necessitating immediate intervention.

- Using Sleipner Dollies: Vibration levels dropped significantly to an average of 0.23 m/s², well below both the action and limit values for an entire 12-hour workday.

Ville Hyvärinen, a specialised occupational hygienist at the Finnish Institute of Occupational Health, remarked: “Using dollies significantly reduces workers’ exposure to whole-body vibration and the resulting health risks, emerging as an excellent way to mitigate vibration. Reducing vibration also improves work comfort, as does a lower sensory noise level in the excavator cab.”

Health and Safety Implications

Whole-body vibration is classified as an occupational disease in several countries, underlining its severity. Prolonged exposure can lead to serious health issues such as lower back pain, joint discomfort, and even foetal risks for pregnant workers. The study’s findings underscore the urgency for industries to adopt measures like Sleipner dollies to safeguard their workforce.

Hyvärinen elaborated: “When driving on tracks for more than three hours during the working day, the employer is obliged to take measures to prevent excessive vibration exposure. Failure to do so risks significant discomfort and pain in the lower back, hip, musculoskeletal joints, and neck area.”

Equipment Longevity and Efficiency

Beyond health benefits, Sleipner dollies also contribute to operational efficiency and cost savings. By minimising vibration, these tools extend the service life of heavy machinery, reducing maintenance costs and downtime. This dual advantage makes them a valuable investment for mining operations worldwide.

Vili Tuominen, a product engineer at Sleipner Finland, commented, “The results of the vibration study exceeded even our own expectations. It’s gratifying to confirm that our products can reduce occupational diseases caused by whole-body vibration while also improving the efficiency of mining operations.”

Regulatory Compliance and Best Practices

Under government regulations, such as Finland’s Decree 48/2005, employers are required to implement vibration prevention programmes when exposure exceeds action values. Failure to comply can lead to significant legal and financial repercussions. Sleipner dollies offer a proactive solution, ensuring compliance while prioritising worker safety.

The study adhered to ISO 2631-1:1997 standards for vibration measurement, using an 8-hour comparison period to evaluate exposure levels. This rigorous approach ensures that the findings are both scientifically valid and actionable.

A Forward-Thinking Approach to Workplace Safety

The benefits of Sleipner dollies extend beyond mining. The principles demonstrated in this study are equally applicable to other heavy industries, such as construction and forestry. By reducing vibration exposure, these innovations pave the way for safer, healthier work environments across sectors.

In addition to reducing health risks, Sleipner’s DB Series lowboy trailers offer similar benefits for other equipment types, such as bulldozers and drills. This versatility makes them an essential tool for any operation prioritising worker safety and efficiency.

Paving the Way for Industry-Wide Adoption

As industries increasingly recognise the importance of mitigating whole-body vibration, solutions like Sleipner dollies are poised to gain traction. Their proven ability to enhance safety, extend equipment longevity, and comply with regulatory standards positions them as an indispensable asset for modern mining operations.

Embracing Innovation for a Safer Future

The findings from the Finnish Institute of Occupational Health serve as a compelling call to action for industry leaders. By embracing innovative solutions like Sleipner dollies, organisations can not only protect their workforce but also achieve greater operational efficiency.

It’s a win-win scenario that sets a new standard for workplace safety and productivity.