Reducing 3D Printing Waste with Eco-Friendly Materials

Let’s be real—waste is a big problem. We toss out so much every day, from plastic containers to old gadgets. But what if we could change that? What if creating things didn’t always mean piles of scraps? This is where 3D printing steps in.

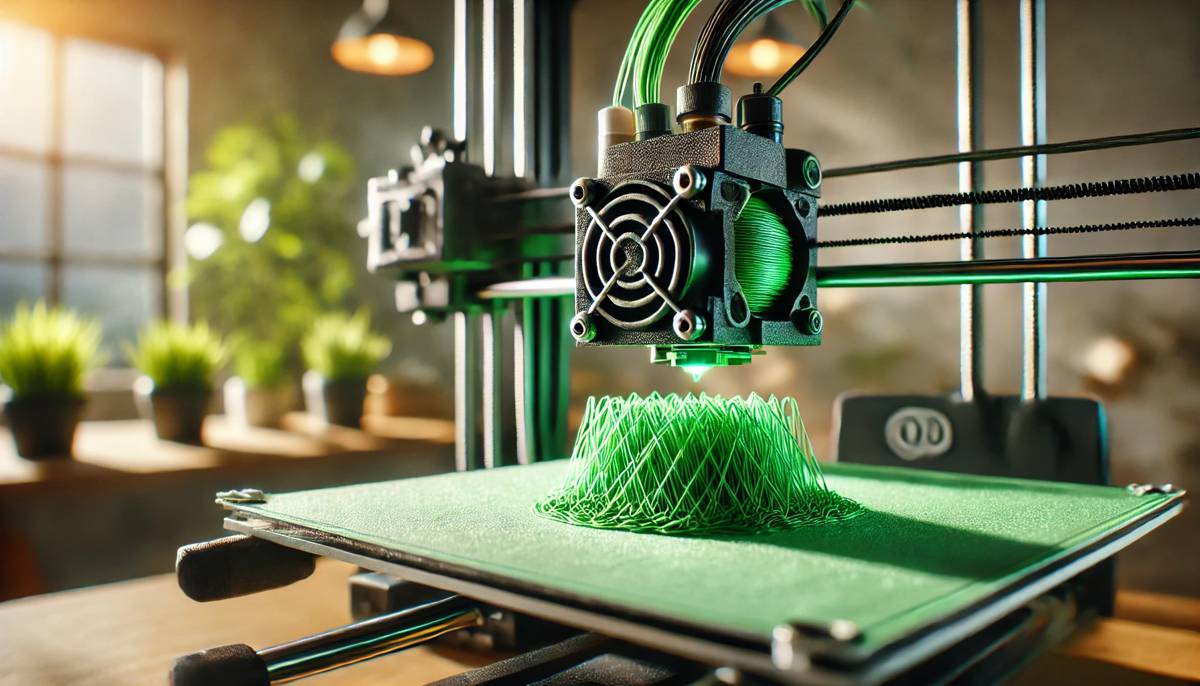

3D printing is like a magic machine that turns digital designs into real objects by layering materials bit by bit. And here’s the cool part: it can be a lot less wasteful than traditional manufacturing, where cutting and shaping materials can leave behind tons of scraps.

For students juggling schoolwork and projects, thinking about sustainable options is important. After all, who doesn’t want to make a positive impact while working on cool creations? Whether you’re printing parts for a science project or considering ways to save time so you can pay someone to do my research paper while still staying eco-friendly, understanding how 3D printing can reduce waste is worth exploring.

What Makes 3D Printing Eco-Friendly?

3D printing can be greener than traditional methods for a few reasons:

- Less material waste: Instead of cutting away extra pieces, 3D printing builds objects layer by layer. No need to carve out shapes and toss the leftovers.

- On-demand printing: You can print exactly what you need, when you need it, instead of mass-producing things that might go unused.

- Longer-lasting products: With custom-made parts, you can repair items instead of throwing them away.

Think of it like building with LEGO bricks. You use just the right pieces to make what you want—nothing extra gets thrown away.

Types of Eco-Friendly 3D Printing Materials

To make 3D printing even greener, there are special materials designed to be sustainable. Let’s look at some of the popular ones:

1. Biodegradable PLA (Polylactic Acid): PLA is made from renewable resources like cornstarch or sugarcane. That means it breaks down more easily than plastics made from fossil fuels.

- Why it’s great: It’s non-toxic and eco-friendly.

- Fun example: Imagine printing a flower pot using PLA—if you ever decide to toss it, it’s much kinder to the planet than regular plastic.

2. Recycled Filaments: Some companies create filaments (the “ink” for 3D printers) from recycled materials like plastic bottles.

- Why it’s great: You’re giving a second life to plastic waste.

- Fun example: Picture your old water bottle turned into a 3D-printed phone stand—talk about an upgrade!

3. Wood-Based Filaments: These filaments mix wood fibers with a base material to give prints a wood-like finish.

- Why it’s great: It has a natural look and feel, and it can use reclaimed wood scraps.

- Fun example: Print a cute mini tree sculpture or a rustic pen holder that looks handmade.

4. Hemp and Coffee-Based Filaments: Yes, you read that right—there are even filaments made with hemp or coffee grounds.

- Why it’s great: These materials repurpose natural waste.

- Fun example: A coffee-scented keychain made from coffee grounds? Pretty cool, right?

How 3D Printing Reduces Manufacturing Waste

Traditional manufacturing often works by carving or cutting materials, which leaves behind unused scraps. Think of sculpting—chunks of material are chipped away and usually thrown out. But 3D printing builds objects from the ground up, layer by layer. Nothing extra gets chopped off.

Here’s why that matters:

- Precision: You can create complex shapes without extra trimming.

- Customization: Instead of mass-producing thousands of identical items, you can print exactly what’s needed.

- Replacement parts: Instead of buying new gadgets, you can print specific parts to fix things.

It’s kind of like cooking from scratch versus buying pre-packaged food—you control the ingredients and make just enough, so less goes to waste.

Creative Ways Students Use Eco-Friendly 3D Printing

Students are finding all kinds of creative ways to use 3D printing sustainably. Here are a few fun ideas:

- School projects: Print reusable project displays instead of using cardboard every time.

- DIY gifts: Instead of buying plastic trinkets, print personalized gifts from sustainable filaments.

- Dorm decor: Make cool decorations or storage organizers with minimal waste.

- Fix-it solutions: Print replacement knobs, hooks, or parts to fix broken items in your dorm room instead of tossing them.

Challenges of Eco-Friendly 3D Printing

Of course, 3D printing isn’t perfect. Here are some challenges to keep in mind:

- Energy use: 3D printers need electricity to run, and some models can be energy-heavy.

- Material choices: Not all 3D printing filaments are eco-friendly, so it’s important to choose wisely.

- Disposal: Even though some filaments are biodegradable, not all of them break down easily in regular home compost bins.

The good news? There are always ways to improve. You can choose low-energy printers or offset energy use by printing during off-peak hours.

Tips for Sustainable 3D Printing

If you’re excited to try 3D printing and want to keep it green, here are some tips:

- Use eco-friendly filaments: Opt for PLA or recycled filaments whenever possible.

- Recycle your scraps: Some companies offer programs where you can send back leftover filament.

- Print only what you need: Avoid printing random items that might end up as clutter.

- Maintain your printer: Keeping your 3D printer in good shape helps avoid printing fails that waste materials.

The Future of Sustainable 3D Printing

3D printing is always evolving. Researchers are working on ways to make printers more energy-efficient and to create even greener materials. Some companies are even experimenting with printing large-scale structures like homes using recycled materials.

Imagine a future where cities are built using recycled 3D-printed parts or where food waste becomes the base for sustainable printing filaments. The possibilities are endless.

Final Thoughts

3D printing has the power to change how we create and consume. By choosing eco-friendly materials and thoughtful printing practices, you can reduce waste and make a positive impact. Whether you’re printing for fun, for school, or to fix something, every small choice adds up.

So, the next time you dive into a 3D printing project, remember: the materials you choose can make a difference. With a little creativity and care, you can help the planet while making something awesome.