Rethinking Value with Generative Economy and Circular Value Chains

How can businesses pivot to a generative economy, and what role do supply chain virtual twins play in this transformation? These questions, addressed by Carlijn Goedhart, Sustainability Lead at DELMIA, unveil a world where waste turns into opportunity and innovation fuels sustainability.

At its core, the generative economy is more than a buzzword—it’s a paradigm shift that redefines the way we produce, consume, and regenerate resources.

What Is the Generative Economy?

In essence, the generative economy is a reimagined circular economy. According to the Ellen MacArthur Foundation, the circular economy is underpinned by three principles:

- Eliminate waste and pollution.

- Circulate products and materials at their highest value.

- Regenerate nature.

While many companies claim to embrace circularity, they often focus solely on reducing waste and recycling materials. DELMIA challenges this notion by promoting a broader vision: a (re)generative economy that doesn’t just sustain but actively replenishes the planet’s resources.

This approach directly counters the “take-make-use-waste” model of traditional supply chains, advocating instead for systems that create long-term ecological and economic balance.

Why the Circular Economy Matters More Than Ever

The linear economy, a model where natural resources are extracted, transformed into products, and discarded as waste, has overstayed its welcome. This unsustainable approach drains the Earth of finite resources, leaving behind mountains of waste and a hefty ecological bill. As materials dwindle and waste accumulates, the call to action is louder than ever.

The circular economy seeks to close this loop by designing products and systems that keep materials in circulation for as long as possible. It’s an evolution of the familiar “reduce, reuse, recycle” mantra, now encompassing additional strategies like refurbishing, remanufacturing, and repurposing. The ultimate goal? Retain value, avoid waste, and regenerate ecosystems.

One automotive company working with Dassault Systèmes revamped its processes to reuse car bumpers instead of recycling them into lower-grade plastic. This not only reduced energy consumption but also eliminated the need for new materials, maintaining the original bumper’s value.

Opportunities in Transitioning to a Circular Economy

The Ellen MacArthur Foundation identifies several pivotal opportunities to accelerate the transition:

- Smarter Product Design: Develop products with longevity in mind, making them easier to repair, upgrade, or disassemble.

- Reverse Logistics Networks: Establish systems to retrieve used products, preventing them from ending up in landfills.

- Collaborative Value Chains: Forge partnerships to optimise material flows and create new circular ecosystems.

Such innovations not only reduce environmental impact but also unlock economic advantages, including cost savings and customer loyalty.

A Catalyst for Circular Manufacturing

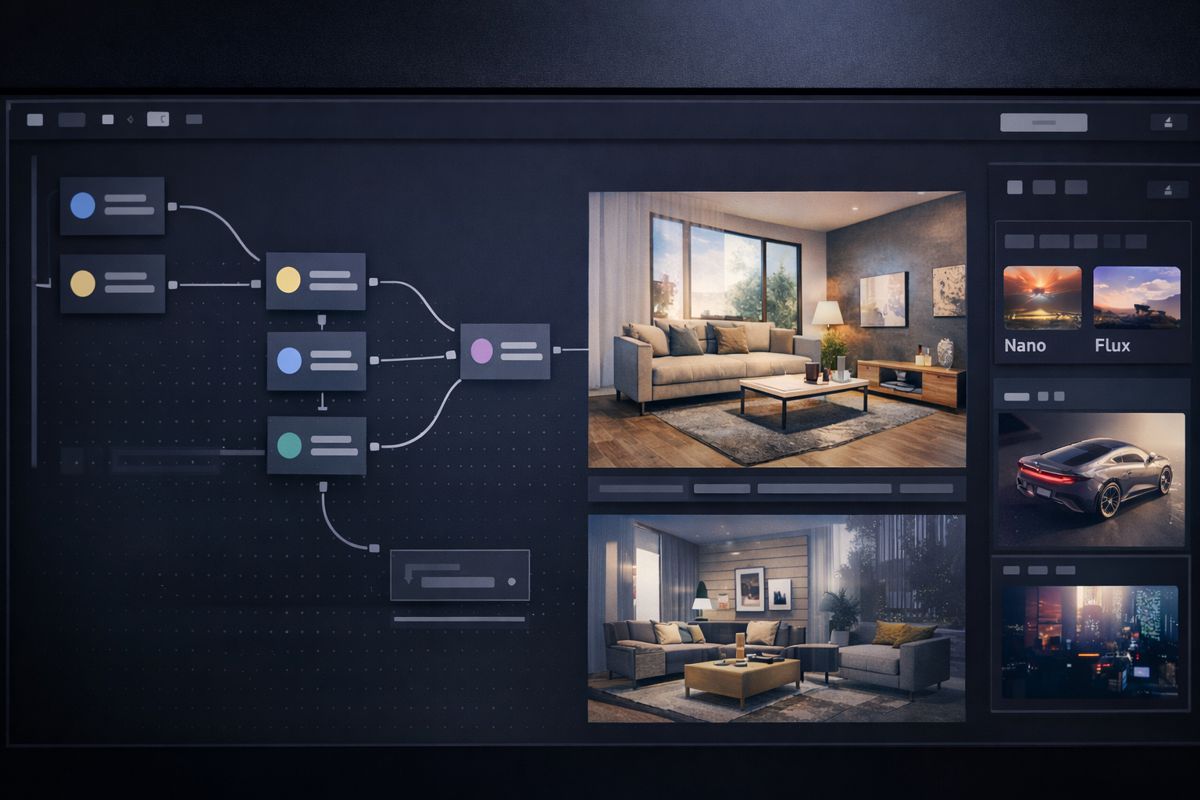

Virtual twin technology is emerging as a game-changer for businesses aiming to embrace circular practices. By creating digital replicas of physical products, manufacturing processes, and supply chains, companies can visualise, simulate, and optimise every step of the production cycle.

Consider DELMIA Quintiq Optimised Planning, which enables businesses to build digital twins of their supply chains. This tool evaluates sourcing scenarios based on key metrics like cost, carbon emissions, and supplier ratings, helping manufacturers strike the right balance between sustainability and profitability.

For example:

- Cost-Driven Scenario: Prioritises low-cost suppliers but may result in higher carbon emissions due to long transport routes.

- Sustainability-Focused Scenario: Sources materials locally from suppliers with eco-friendly practices, at a higher cost.

- Balanced Approach: Aims to reduce emissions while maintaining reasonable costs, creating a win-win solution.

By running simulations in a virtual environment, companies can identify the most efficient and sustainable sourcing strategies before implementing them in the real world.

Waste as a Resource

In a circular economy, waste isn’t a problem—it’s an opportunity. Transforming waste into raw materials requires collaboration, innovation, and the right tools.

- Aluminium Recycling Done Right: One DELMIA customer in the aluminium industry reduced reliance on virgin materials by meticulously sorting scrap aluminium. By leveraging DELMIA Quintiq, the company could plan optimal production batches using available scrap, ensuring high-quality outputs while reducing waste and costs.

- Expanding the Network: Circular value chains often extend beyond individual organisations. Industries such as steel and aluminium are seeing cross-sector collaborations where raw material producers, manufacturers, and waste management companies team up to keep resources circulating. These partnerships demonstrate that circularity isn’t just feasible—it’s profitable.

The Role of Supply Chain Virtual Twins in the Generative Economy

Supply chain virtual twins don’t just optimise individual processes; they enable systemic change. By providing real-time insights into material flows, emissions, and costs, these digital tools empower companies to make data-driven decisions that align with their sustainability goals.

Virtual twins also help businesses navigate the complexities of setting up reverse logistics, integrating circularity metrics into KPIs, and building partnerships across the value chain. The result? Resilient, sustainable supply chains that benefit both the planet and the bottom line.

A Regenerative Future

The generative economy is no longer a far-off ideal—it’s a necessity. By embracing circular principles and leveraging cutting-edge technologies like virtual twins, companies can turn sustainability from a challenge into a competitive advantage. As Carlijn Goedhart aptly puts it: “The generative economy isn’t just about reducing harm; it’s about actively creating value—for businesses, for people, and for the planet.”

The future of manufacturing lies in systems that don’t just sustain but thrive, regenerating resources and redefining success in a rapidly changing world.