A Guide to Respiratory Protection in Construction

Respiratory protection is a cornerstone of occupational safety, particularly in the construction industry where workers are routinely exposed to hazardous airborne particles, gases, and vapours.

Ensuring respiratory safety isn’t just about compliance—it’s about safeguarding lives and health in one of the world’s most challenging work environments. This guide dives deep into the importance of respiratory protection, industry insights, statistics, and emerging technologies shaping the future.

Why Respiratory Protection is Critical

In construction, respiratory hazards are omnipresent. From the dust clouds generated by concrete cutting to the toxic fumes of welding and painting, airborne contaminants pose significant risks. These hazards are not confined to specific job roles but span across tasks as diverse as demolition, refurbishment, and installation processes.

Workers may unknowingly expose themselves to microscopic particles and gases that are invisible to the naked eye yet highly detrimental to their health. Prolonged exposure to these hazards can lead to life-altering conditions such as:

- Silicosis: A severe lung disease caused by inhaling crystalline silica dust. Symptoms often take years to manifest but can progress rapidly once they appear, leading to breathing difficulties and irreversible lung damage.

- Asbestosis: A chronic condition resulting from exposure to asbestos fibres. This often affects construction workers involved in renovating older buildings where asbestos-containing materials are present.

- Chronic Obstructive Pulmonary Disease (COPD): A result of long-term exposure to irritants like dust and chemical fumes. This condition significantly diminishes lung function and quality of life over time.

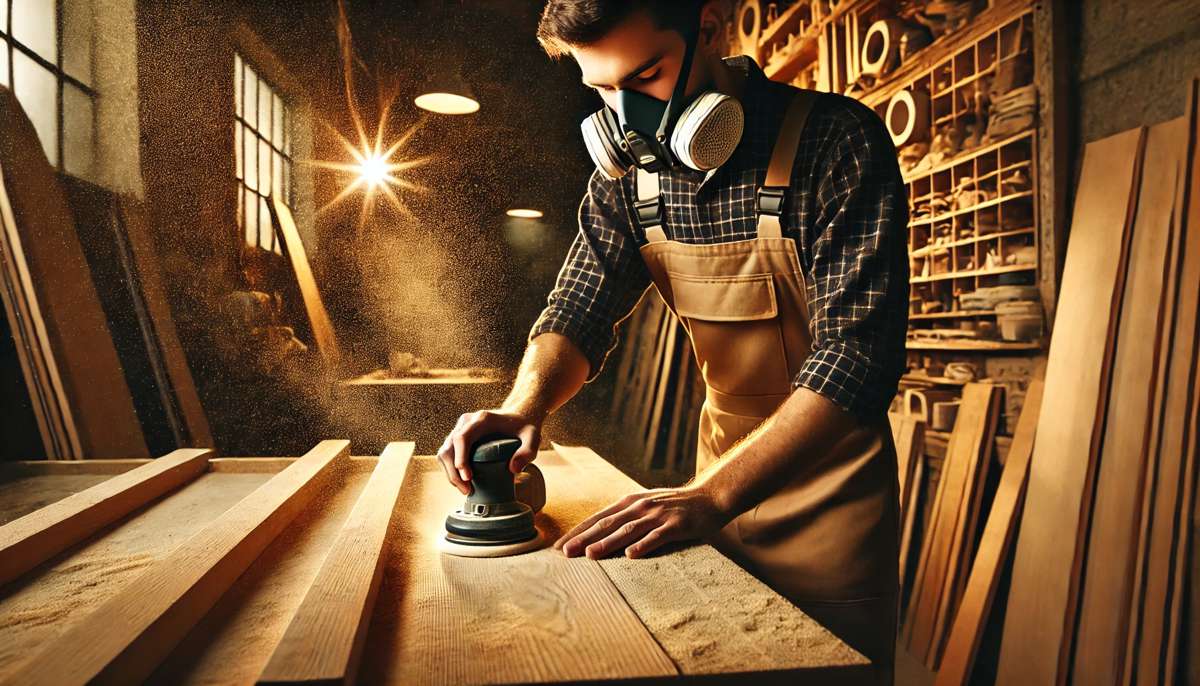

- Occupational Asthma: Triggered by inhaling allergens or irritants present in construction sites. Common triggers include wood dust, adhesives, and paint sprays, causing persistent coughing and wheezing.

Key Statistics

- According to the World Health Organization, over 2 million deaths annually are linked to workplace exposure to airborne pollutants. These numbers underscore the global impact of occupational respiratory hazards.

- Silica dust alone contributes to 46,000 deaths globally each year, as reported by the International Labour Organization. The risks associated with silica dust remain a persistent challenge for industries reliant on materials like concrete, brick, and stone.

- The National Institute for Occupational Safety and Health (NIOSH) estimates that 1 in 4 construction workers may be exposed to silica levels exceeding permissible exposure limits (PELs). This startling statistic highlights the widespread prevalence of inadequate protective measures.

- A 2023 study revealed that nearly 30% of construction workers neglect proper respirator usage due to discomfort, lack of training, or unavailability, amplifying their vulnerability to airborne hazards.

Beyond these alarming numbers, the financial toll of respiratory diseases is equally staggering. Workplace respiratory illnesses result in billions of dollars annually in healthcare costs, lost productivity, and compensation claims. Addressing these risks through stringent safety protocols and advanced PPE solutions is not only a moral imperative but also a financial necessity for employers.

Moreover, the psychological effects of respiratory illnesses on workers and their families cannot be overstated. As individuals grapple with chronic health conditions, the emotional burden often extends to loved ones, further emphasizing the importance of preventive measures and early intervention. The construction industry, known for its fast-paced and high-stress environment, must prioritize respiratory safety to ensure a healthier, more resilient workforce.

Types of Respiratory Hazards in Construction

Particulate Matter

- Sources: The most common sources include concrete cutting, drilling, demolition, and sanding. Activities like material transport and site preparation can also generate significant amounts of particulate matter, often invisible to the naked eye but harmful when inhaled. Dust from these tasks contains harmful crystalline silica particles that can easily enter the respiratory system.

- Risks: Silicosis, a debilitating lung disease, remains one of the gravest risks, affecting thousands of workers annually. Long-term exposure increases the risk of lung cancer and chronic bronchitis. Respiratory irritation caused by prolonged exposure can lead to coughing, wheezing, and shortness of breath, which can severely impact productivity and quality of life.

Fumes

- Sources: Welding, soldering, and hot work are significant contributors to hazardous fumes. The intense heat from these processes vaporizes metals and flux materials, creating fumes containing toxic substances like manganese, chromium, and nickel. Cutting or grinding painted or coated materials can release additional harmful particles.

- Risks: Metal fume fever is a common condition experienced by workers exposed to these fumes, characterized by flu-like symptoms. Chronic exposure can lead to serious respiratory issues, including pneumoconiosis and asthma. Prolonged inhalation of certain metal fumes, such as cadmium or beryllium, can even cause damage to the kidneys and nervous system.

Gases and Vapours

- Sources: Common sources include painting, solvent use, and chemical cleaning agents. These activities often release volatile organic compounds (VOCs) and other hazardous gases like carbon monoxide or ammonia. In poorly ventilated areas, these gases can accumulate to dangerous levels.

- Risks: Toxic exposure to gases and vapours can result in both acute and chronic health effects. Immediate symptoms may include dizziness, headaches, and nausea, while long-term exposure increases the risk of organ damage, including severe respiratory illnesses and nervous system disorders. Asphyxiation is a particularly severe risk in confined spaces where oxygen levels can drop rapidly.

Biological Hazards

- Sources: Mould, bacteria, and viruses thrive in poorly ventilated or water-damaged sites. Materials like wood, drywall, and insulation can harbour these biological agents if exposed to moisture for extended periods. Workers in flood-affected areas or during post-disaster clean-ups face heightened exposure.

- Risks: Allergic reactions to mould spores are common and can range from mild to severe. Chronic exposure to biological hazards can lead to long-term conditions like hypersensitivity pneumonitis or occupational asthma. Infections caused by bacteria and viruses can also spread rapidly in crowded job sites, posing a health risk to workers and their families.

Types of Respirators and Their Applications

Selecting the right respirator depends on the type of hazard, work environment, and the specific tasks being performed. Below is a detailed overview of the most commonly used respiratory protection devices, along with their advanced applications and emerging trends:

Disposable Respirators (Filtering Facepieces)

- Ideal for: Particulates like dust and non-toxic fumes, often encountered during sanding, sweeping, or light demolition tasks.

- Example: N95 masks, which filter out 95% of airborne particles, are a staple in many construction projects. Variants such as R95 and P95 masks provide added resistance to oil-based particulates.

- Advantages: Lightweight, cost-effective, and widely available.

- Limitations: Ineffective against gases, vapours, and high concentrations of dust, and unsuitable for extended use in high-hazard environments.

- Latest Trends: Manufacturers are incorporating adjustable nose clips and advanced filtration layers to improve comfort and efficiency, catering to longer wear times.

Half-Face Respirators

- Features: Equipped with replaceable cartridges and filters designed to handle specific contaminants such as organic vapours, acid gases, or fine particulates.

- Applications: Frequently used in environments with moderate exposure to dust, mists, and certain gases, such as during painting, pesticide application, or cutting materials containing silica.

- Advantages: Provides a tighter seal and offers higher protection than disposable options while remaining relatively lightweight.

- Drawbacks: Requires proper maintenance and periodic replacement of cartridges.

- Emerging Trends: Enhanced ergonomic designs, lightweight materials, and compatibility with other PPE, such as hard hats and safety glasses, are becoming standard.

Full-Face Respirators

- Features: Encloses the entire face, offering integrated protection for eyes, nose, and mouth.

- Applications: Suitable for high-hazard environments with significant exposure to hazardous particles, gases, or vapours, such as in asbestos abatement or chemical handling.

- Advantages: Protects both respiratory and ocular systems, reduces risk of eye irritation, and provides superior sealing capabilities.

- Drawbacks: Bulkier and can limit peripheral vision, potentially impacting mobility.

- Future Developments: Anti-fog coatings, lightweight polymers, and integrated communication systems are revolutionizing usability and safety.

Powered Air-Purifying Respirators (PAPRs)

- Mechanism: Employs a battery-powered blower to actively pull contaminated air through filters, supplying purified air to the user.

- Best For: Long-duration tasks in environments with high dust or particulate concentrations, such as abrasive blasting or grain handling.

- Advantages: Offers greater comfort by reducing breathing resistance and maintains airflow, reducing fatigue during extended use.

- Example: Widely used in asbestos remediation and industrial cleaning projects.

- Innovations: Recent models incorporate lightweight battery packs, variable airflow settings, and advanced filtration for enhanced usability.

Supplied-Air Respirators (SARs)

- Features: Delivers clean air from an external source, ensuring a constant supply free of contaminants.

- Applications: Ideal for confined spaces or environments with extremely hazardous airborne contaminants, such as chemical storage tanks or sewers.

- Key Advantages: Eliminates reliance on ambient air, making it invaluable for scenarios where contaminants are overwhelming or oxygen levels are depleted.

- Challenges: Requires extensive setup and proper hose management, which can hinder mobility.

- Technological Advancements: Modern SARs feature quick-connect systems, improved hose durability, and compatibility with mobile air sources.

Self-Contained Breathing Apparatus (SCBA)

- Features: Equipped with an independent air supply, usually in the form of an air tank, ensuring complete autonomy from the surrounding environment.

- Uses: Critical for emergency response teams, firefighting, and entry into confined spaces with immediately dangerous to life or health (IDLH) conditions.

- Advantages: Provides unmatched protection in environments with unknown or rapidly changing hazards.

- Drawbacks: Bulky and requires rigorous training for proper use and maintenance.

- Latest Developments: Innovations in lightweight materials, extended-duration tanks, and digital displays that monitor remaining air supply are enhancing the functionality of SCBA systems.

Standards for Respiratory Protection

The Occupational Safety and Health Administration (OSHA) has strict guidelines for respiratory protection in construction, but globally, other standards are also instrumental in ensuring safety across diverse industries and regions.

These guidelines help harmonize practices and ensure that workers’ health is protected regardless of location. Key standards and their requirements include:

OSHA (United States)

- Hazard Assessment: Employers must conduct a thorough assessment to identify airborne hazards.

- Written Respiratory Protection Program: Required for workplaces where respirators are necessary.

- Training: Employees must be trained in proper respirator use, maintenance, and limitations.

- Fit Testing: Mandatory annual testing to ensure a proper seal between the respirator and the user’s face.

- Medical Evaluations: Workers must be evaluated to ensure they can safely use respirators.

European Union Standards (EN 149 and EN 143)

- Classification of Respirators: Masks are categorized based on efficiency levels—FFP1, FFP2, and FFP3—with FFP3 offering the highest level of filtration.

- Filter Testing: Stringent tests ensure filters can effectively block particulates, oil-based aerosols, and other contaminants.

- Marking and Certification: All respirators must have CE marking to confirm compliance with EU safety directives.

- Periodic Fit Checks: Employers must facilitate regular fit testing and user training, similar to OSHA’s guidelines.

Australian/New Zealand Standards (AS/NZS 1716:2012)

- Respirator Design: Covers performance requirements for particle, gas, and combination filters.

- Workplace Application: Stipulates proper respirator use based on risk assessments, emphasizing adherence to compatibility with other PPE.

- Inspection and Maintenance: Emphasizes the importance of routine inspection and timely replacement of filters.

- Fit Testing Protocols: Aligns closely with international practices to ensure effective sealing.

Canada (CSA Z94.4-18)

- Comprehensive Guidelines: Focuses on selection, use, and care of respirators in hazardous environments.

- Employer Responsibility: Requires a Respiratory Protection Program tailored to specific workplace hazards.

- Quantitative Fit Testing: Promotes high standards of testing to ensure masks meet the demands of Canadian work environments.

- Thermal and Humidity Performance: Assesses respirator efficiency under extreme environmental conditions.

Global Insights and Best Practices

- ISO Standards (ISO 16900 series): International standards for testing respiratory protective devices cover filtration efficiency, resistance to breathing, and field performance testing. These provide a universal benchmark for manufacturers and safety managers alike.

- China (GB2626-2019): Enforces rigorous testing standards for respirators, including KN95 masks, widely recognized for their efficiency and reliability in industrial and medical settings.

- India (BIS IS 9473): Specifies technical requirements for filtering half masks, mirroring EN and ISO standards to meet growing industrial needs.

Key Global Requirements

- Training and Awareness: Across regions, comprehensive training ensures that workers understand the importance of respirator usage and maintenance.

- Adaptability to Local Conditions: Respiratory programs often integrate environmental considerations, such as humidity and temperature, into PPE requirements.

- Standardized Testing Protocols: Frequent performance evaluations ensure masks meet the demands of various industrial hazards, promoting consistent quality.

Promoting a Culture of Safety

Ensuring respiratory safety requires more than providing equipment—it necessitates a culture of safety where:

- Employers prioritize the well-being of workers by investing in high-quality PPE and training. This includes not just providing the best equipment but also ensuring that workers understand its importance, are well-versed in its use, and feel comfortable raising concerns about potential respiratory hazards. Employers should foster an open dialogue about safety practices and create channels for feedback to continually improve safety protocols.

- Employees take personal responsibility for adhering to safety protocols and using equipment correctly. Workers must remain vigilant about their health and respiratory safety, keeping abreast of training updates and best practices. Encouraging a mindset of mutual accountability among colleagues can reinforce safety as a shared responsibility.

- Industry leaders advocate for stricter standards and advancements in respiratory technology. This entails pushing for innovations that make protective equipment more comfortable, durable, and accessible. Leaders can influence legislation and regulatory practices to adopt higher safety benchmarks and ensure that emerging technologies benefit all workers universally.

Fostering a Safer Environment

A culture of safety extends beyond meeting regulatory requirements. It involves embedding safety into the organizational ethos. Regular safety workshops, leadership demonstrating a commitment to worker well-being, and ongoing safety audits are integral to this effort. A proactive approach, where potential hazards are addressed before they become risks, reflects a commitment to valuing human lives over operational efficiency.

Respiratory protection is not just a regulatory requirement—it’s an essential component of worker safety and health in construction. By staying informed about hazards, investing in appropriate PPE, and embracing technological innovations, the industry can create safer work environments where every breath is protected.

The future of respiratory safety hinges on collaboration between employers, employees, and industry leaders. By uniting efforts to innovate, educate, and enforce high standards, we can ensure that workplaces prioritize health above all else. Let’s pave the way for a safer construction industry where no worker’s health is compromised for progress. For teams looking to upgrade their protective gear, there are many reputable suppliers offering N95 masks for sale, making it easier to source high-quality respiratory protection that meets industry standards.