Mecbo America Scorpion Concrete Crawler Boom for Hard-to-Reach Projects

Mecbo America, a division of Blastcrete Equipment LLC, has introduced a cutting-edge solution to concrete placement challenges: the Scorpion Concrete Crawler Boom.

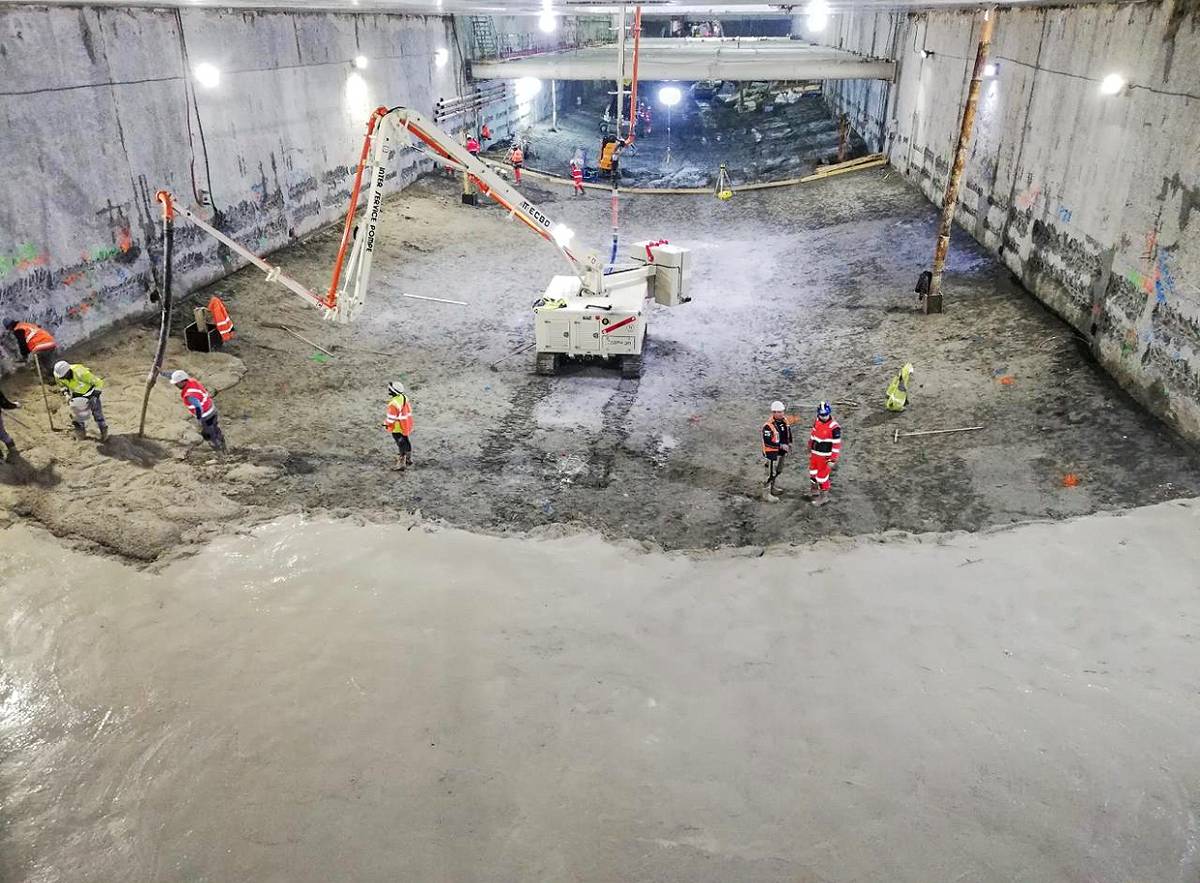

Designed to enhance efficiency on piling, drilling, tunnelling, and commercial construction sites, this innovative machine offers contractors a flexible, cost-effective way to deliver concrete exactly where it’s needed without disrupting the job site.

Scott Knighton, co-CEO of Blastcrete, highlighted the growing demand for a boom among contractors: “As concrete contractors grow and the scope of their work changes, many recognize the need for a boom. The Scorpion provides that benefit without the added expense of another pump.”

Let’s take a closer look at why this compact but powerful crawler boom is set to make waves in the industry.

Unparalleled Reach and Manoeuvrability

One of the most compelling aspects of the Scorpion is its unmatched reach and adaptability. With a vertical reach of 52 feet and a horizontal span of 46 feet, this 10-ton crawler boom can extend over obstacles like structures, landscaping, and restricted-access areas.

What’s more, its impressive 370° rotation ensures seamless manoeuvrability, making it an indispensable tool for highway overpasses, large commercial buildings, and other challenging construction environments.

Before the Scorpion, contractors faced frustrating and costly delays when trying to work around physical barriers. Traditional solutions often required additional equipment or extensive site modifications. Now, the Scorpion eliminates these inefficiencies by offering a highly versatile placement system that navigates complex sites effortlessly.

Continuous Concrete Flow for Maximum Efficiency

Unlike traditional booms, which often require stabilisers, the Scorpion operates without outriggers. This means operators can continue pumping while the machine is in motion, drastically improving workflow and project timelines.

The ability to customise the machine for extended reach beyond 52 feet further enhances its appeal, ensuring that contractors can tailor it to their specific project needs. Whether dealing with high-rise applications or hard-to-reach spots, the Scorpion provides an agile, uninterrupted concrete delivery solution.

Advanced Technology for Operator Convenience

Efficiency doesn’t stop at reach and flexibility—the Scorpion also boasts cutting-edge technology designed with the operator in mind. Standard across all units is a handheld radio control, allowing seamless manipulation of both the boom and undercarriage with minimal effort.

For power, contractors have the choice between a 50-horsepower electric motor or a 30-horsepower diesel engine—the latter available with a soundproofing option for noise-sensitive job sites.

The boom’s foldable ‘Z’ configuration also makes transportation a breeze, allowing it to fit securely onto a standard trailer.

A Strategic Collaboration: Mecbo America and Blastcrete Equipment LLC

Mecbo America is the result of a powerful distribution agreement between Blastcrete Equipment LLC and Mecbo Srl, a leading Italian manufacturer of concrete equipment.

This collaboration provides contractors across North, Central, and South America with direct access to Mecbo’s innovative products while reinforcing Blastcrete’s offerings with state-of-the-art Mecbo pump technology.

Under this agreement, Mecbo America will distribute multiple Mecbo models, and Blastcrete will integrate Mecbo’s pump technology into their trailer-mounted pump designs. This synergy is particularly beneficial for applications such as:

- Pool installation – where precision and efficiency in concrete placement are critical.

- Deep foundation work – requiring high-volume pumping for stability and durability.

- Tunnelling and infrastructure projects – demanding advanced mobility in tight spaces.

With both companies boasting extensive industry experience, contractors can expect unparalleled product support, spare parts availability, and after-sales service, ensuring long-term reliability and efficiency.

Over 70 Years of Innovation

Blastcrete Equipment LLC has spent over seven decades refining its product line, developing some of the most reliable, safe, and user-friendly solutions in the concrete, refractory, and shotcrete industries.

With a diverse range of mixers, pumps, and placement equipment, Blastcrete serves markets including:

- Commercial and residential construction

- Refractory applications

- Underground construction

- Insulated Concrete Form (ICF) markets

Their collaboration with Mecbo further cements their position as an industry leader, providing contractors with cutting-edge technology that simplifies operations, reduces downtime, and enhances efficiency on the job.

The Future of Concrete Placement

The launch of the Scorpion Concrete Crawler Boom represents a pivotal shift in the way contractors handle complex concrete placement projects. With its unmatched flexibility, continuous pumping capability, and robust technology, the Scorpion is set to become an essential asset on job sites where efficiency and safety are paramount.

By eliminating many of the traditional barriers to concrete placement, Mecbo America is not just introducing a new product—they’re redefining how contractors approach their work. As the construction industry moves towards more advanced, automated solutions, innovations like the Scorpion will continue to streamline operations and improve job site productivity.

For those looking to enhance efficiency without the added cost of a second pump, the Scorpion is undoubtedly a game-changer in the world of concrete placement.