Pushing the Boundaries of Hydrodemolition with Aquajet Aqua Rail System 3

Aquajet, the Swedish powerhouse behind some of the most advanced Hydrodemolition solutions on the market, has once again raised the bar with the launch of the Aqua Rail System 3.0.

This cutting-edge system is built to maximise flexibility, precision, and efficiency in some of the most complex construction scenarios imaginable — think tunnels, silos, dams, and bridge walls.

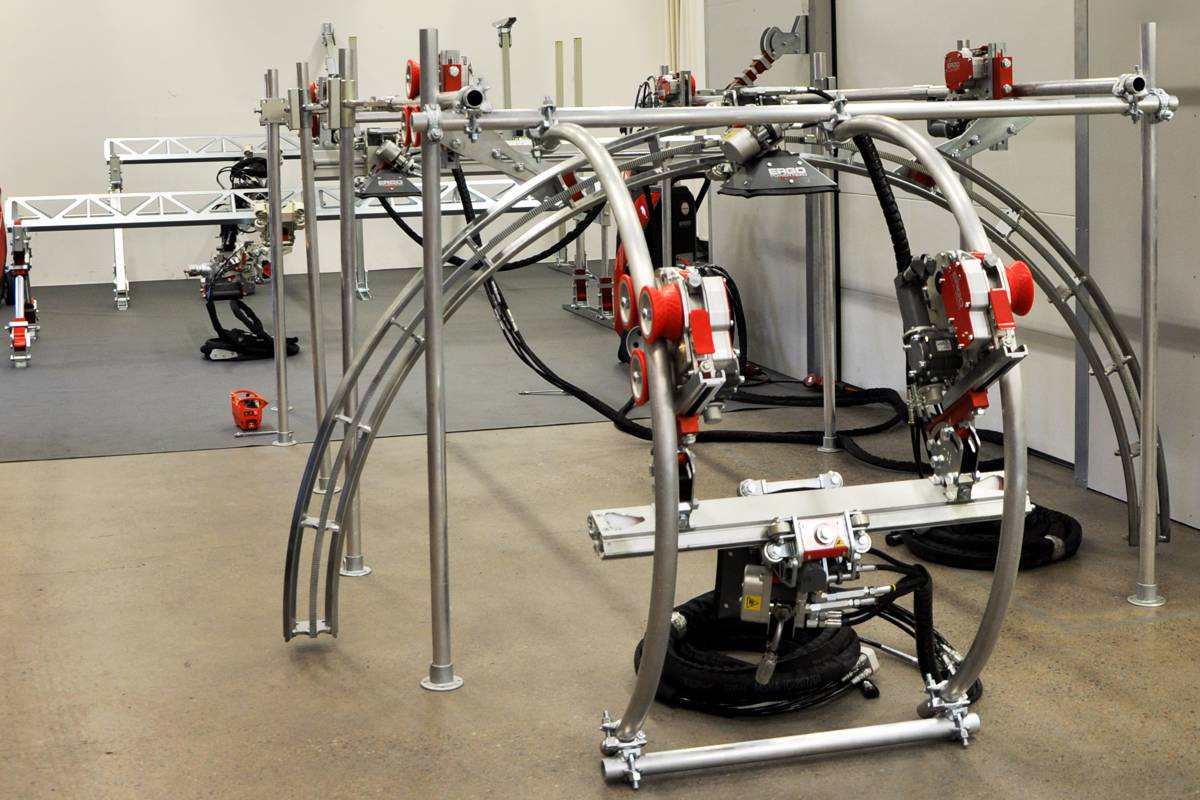

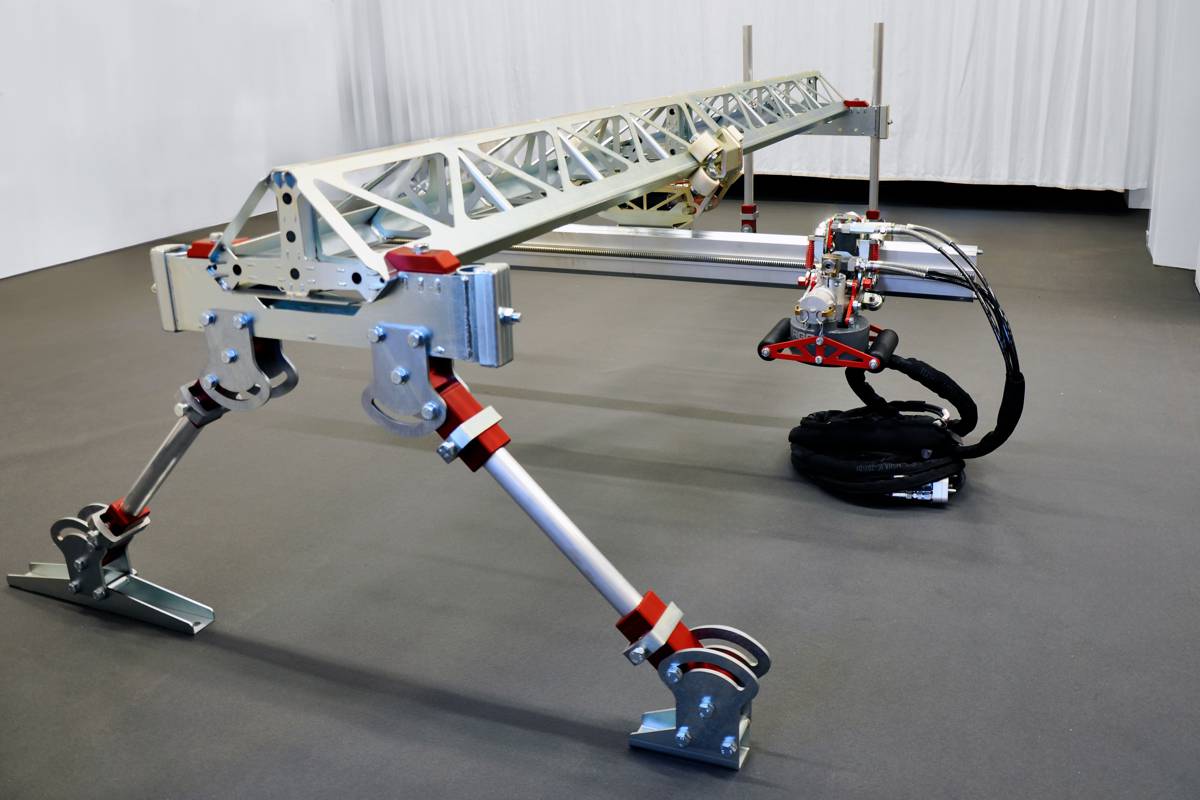

At the heart of the new system lies the upgraded Aqua Spine 3.0 — a versatile, extendable rail system designed to support Aquajet’s Hydrodemolition robots in environments where standard flatwork solutions just won’t cut it. Designed with adaptability in mind, it mounts securely to almost any surface and provides a robust track for the Power Head to traverse smoothly. Alongside it, the Ergo Climbers 3.0 bring an extra layer of adaptability with their completely redesigned beam brackets, clamping systems and passable mounts.

A Smart Answer to Real Jobsite Challenges

“We noticed a pain point where contractors are still using hand lances for jobs that can be accomplished more quickly with a Hydrodemolition robot, given the right setup,” explained Roger Simonsson, Managing Director of Aquajet.

To solve that challenge, Aquajet didn’t just improve the Aqua Spine and Ergo Climbers – they also built a fully modular, reconfigurable Support System. This game-changing component allows contractors to tailor setups precisely to the job at hand, thanks to adjustable legs, swivel joints, and smart brackets that give the system a kind of LEGO-like adaptability.

And here’s the best part: the Aqua Rail System 3.0 isn’t just a one-trick pony. It’s compatible with Aquajet’s Aqua Cutter 750V, 450A, and 450V Hydrodemolition robots, along with the Ergo system, making it a truly scalable investment for contractors.

Expanding the Scope of Hydrodemolition

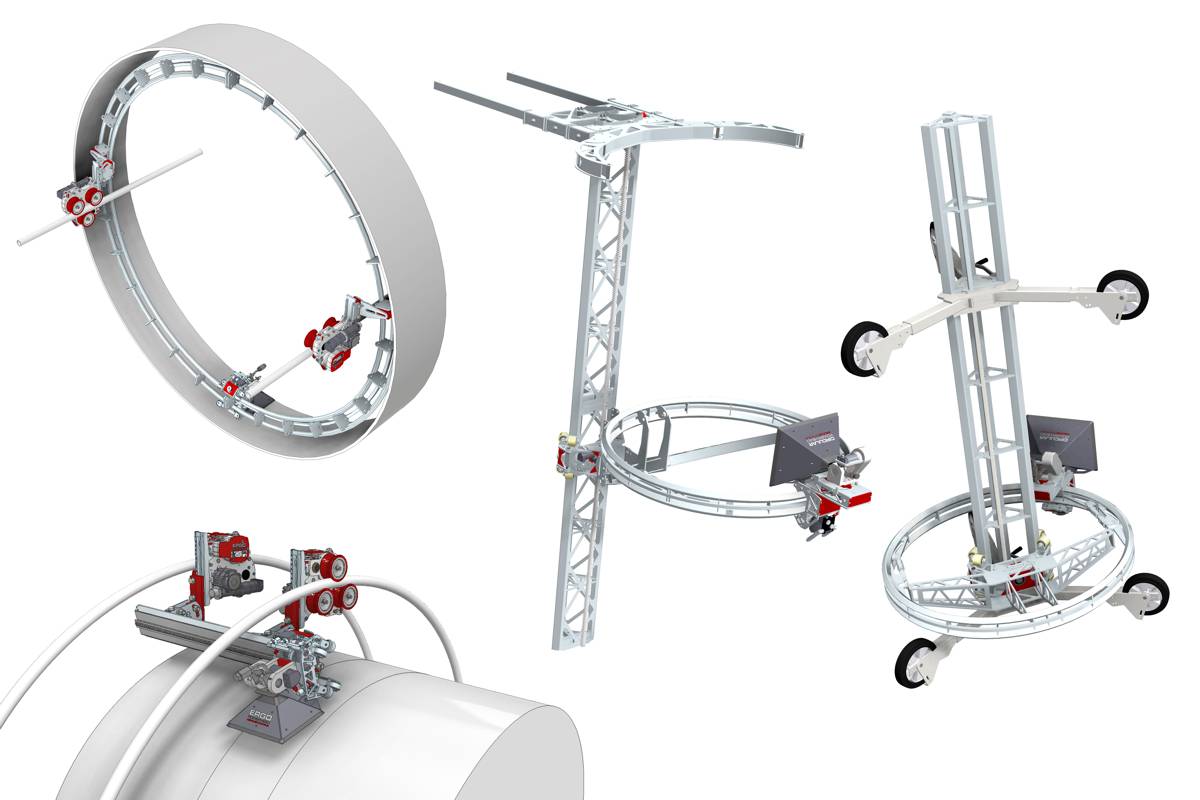

The Aqua Spine 3.0 opens the door to new possibilities for both linear and circular applications. From vertical walls in power plants to curved tunnel linings and cylindrical pillars, it adapts without missing a beat.

Key highlights of the Aqua Spine 3.0 include:

- Passable Mounts: Allow seamless transition of the Power Head across sections without stop-and-reposition delays.

- Lightweight & Tougher: The new model is not only lighter but can handle 60% more load and 50% more torque compared to its predecessor.

- Circular Adaptability: Thanks to compatibility with the Aqua Centralizer and Circular Power Head, users can create a full circular setup — ideal for internal tunnel and pipe work.

- Tool-Free Assembly: Built with M16 or M20 bolts, assembly and adjustments can be done quickly with minimal tools.

Redesigned Ergo Climbers Bring Endless Mobility

When mounted to scaffolding or roller beams, the upgraded Ergo Climbers 3.0 are no longer restricted by length or shape. Their improved beam brackets now allow for height and angle adjustments, while the new passable brackets let the Power Head move fluidly along the entire scaffold.

In practical terms, that means fewer interruptions, more productivity, and significantly better coverage. Whether it’s pipes, pillars, or curved structures, contractors can now deploy a continuous circular setup, increasing precision and eliminating bottlenecks.

The Power of a Customisable Support System

Of course, even the most capable hardware needs a solid foundation. That’s where Aquajet’s new modular Support System steps in. Featuring only nine interchangeable parts, this system lets users construct a 360-degree rotation platform for their Aqua Spine or Ergo setup.

Each component has been designed with adaptability and simplicity in mind:

- Quick Assembly: Built with a standardised CC80 hole pattern and M16 bolts.

- Adjustable Legs & Joints: Angle and height modifications are easy to implement.

- Two Weight Classes: Choose from light (for Ergo setups) or heavy-duty (for more powerful machines like the Aqua Cutter 750V).

As Roger Simonsson put it: “The true value lies in its reusability and scalability. If a future project requires different specifications, the system can be reconfigured or expanded with additional components.”

Designed for Real-World Complexity

Construction rarely happens on a perfectly flat surface. That’s why the Aqua Rail System 3.0 has been engineered with real-world job sites in mind. It works just as well on floors and ceilings as it does on vertical walls. That means fewer compromises and more time spent on actual demolition work.

Thanks to the flexibility of the rail system and support legs, contractors can achieve optimal machine placement, even in hard-to-reach or oddly angled locations. And since the system is modular, they won’t need to buy a whole new kit for every new challenge.

A Global Leader with a Legacy of Innovation

Aquajet has earned its reputation as the leader in Hydrodemolition solutions not just through innovation but consistency. Since being acquired by Brokk AB in 2016, the company has expanded its global footprint while staying true to its Swedish roots. From its headquarters and production base in Holsbybrunn, Sweden, Aquajet supplies premium equipment to contractors around the globe.

With the Aqua Rail System 3.0, they’re not just launching a product — they’re providing contractors with a competitive edge in productivity, safety, and operational flexibility.

Spotlight at bauma 2025

Aquajet is set to showcase the Aqua Rail System 3.0 and a suite of other Hydrodemolition innovations at bauma 2025, taking place from April 7-13 in Munich. Visitors can experience the system up close at Stand A1.325, where the Aquajet team will offer live demos, technical guidance, and one-on-one consultations.

This is more than just a product reveal; it’s an invitation to witness the future of Hydrodemolition first-hand.

Ready for What’s Next

The Aqua Rail System 3.0 signals a clear shift in how Hydrodemolition work can be approached. By prioritising modularity, reusability, and on-site flexibility, Aquajet isn’t just solving today’s problems — they’re future-proofing the industry.

In a world where infrastructure maintenance and upgrades are becoming increasingly complex, systems like this offer a vital combination of precision, speed, and adaptability. For contractors looking to cut downtime and boost performance across a range of structures and materials, Aquajet’s new release couldn’t come at a better time.