Schindler R.I.S.E Robot Makes UK Debut at London’s Greenest Office Scheme

London’s skyline is on the cusp of a quiet revolution. Not because of its height, but because of how it’s being built. The UK’s largest all-electric office scheme, 105 Victoria Street, is now home to a remarkable piece of kit that’s drawing international attention as Schindler R.I.S.E, the world’s first Robotic Installation System for Elevators, has officially made its British debut.

Crafted by the globally-renowned lift and escalator manufacturer Schindler Group, this robotic marvel is currently working away inside BGO’s flagship development in central London.

It’s a first for the UK, but hardly the first outing for Schindler R.I.S.E, which has already proven its mettle on sites across Europe, the Middle East, and Asia. Still, its arrival on British soil is a major milestone—not just for Schindler, but for the entire construction sector.

What Makes Schindler R.I.S.E So Revolutionary?

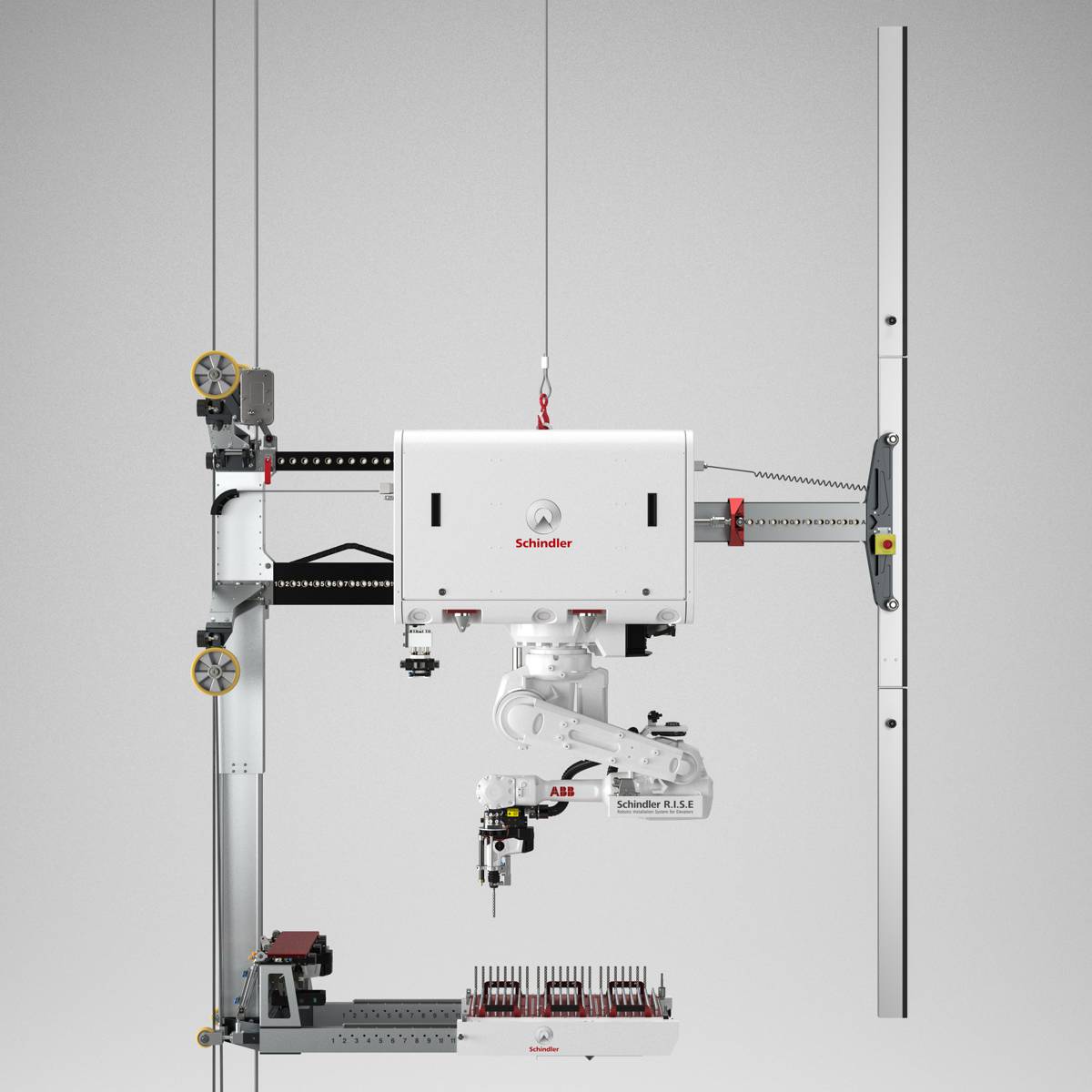

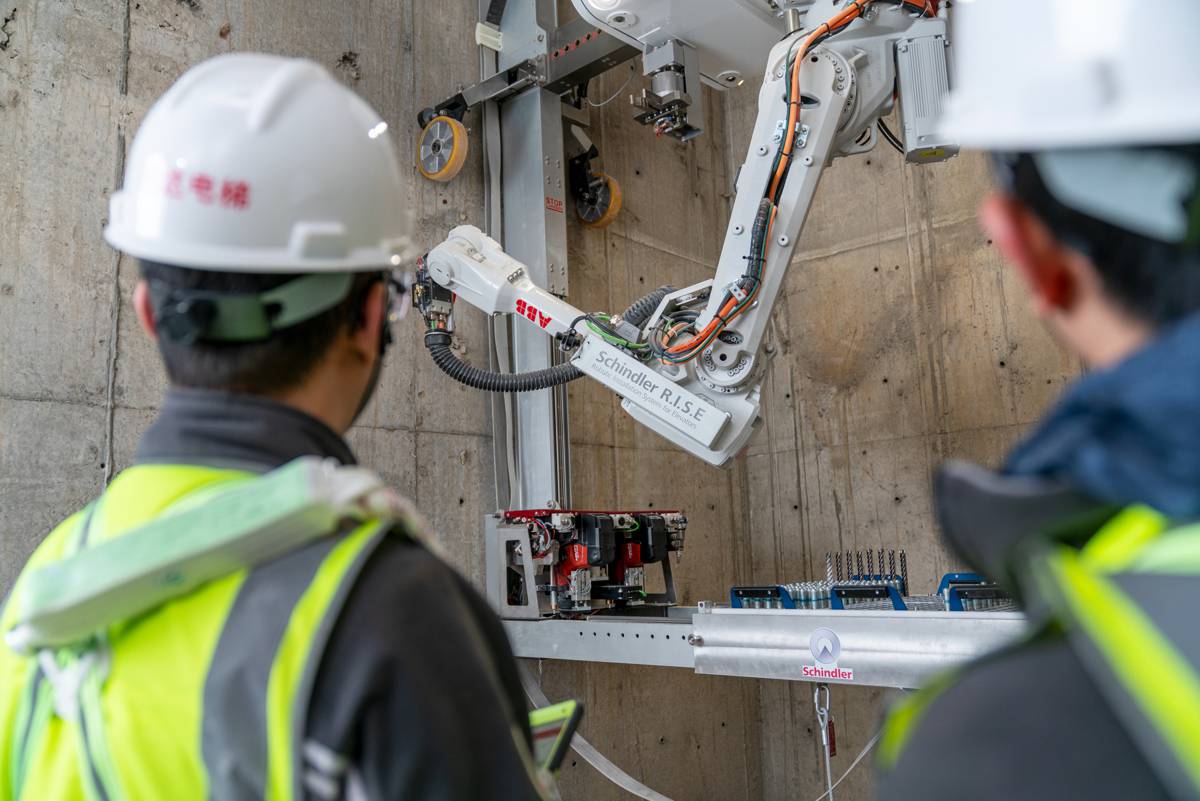

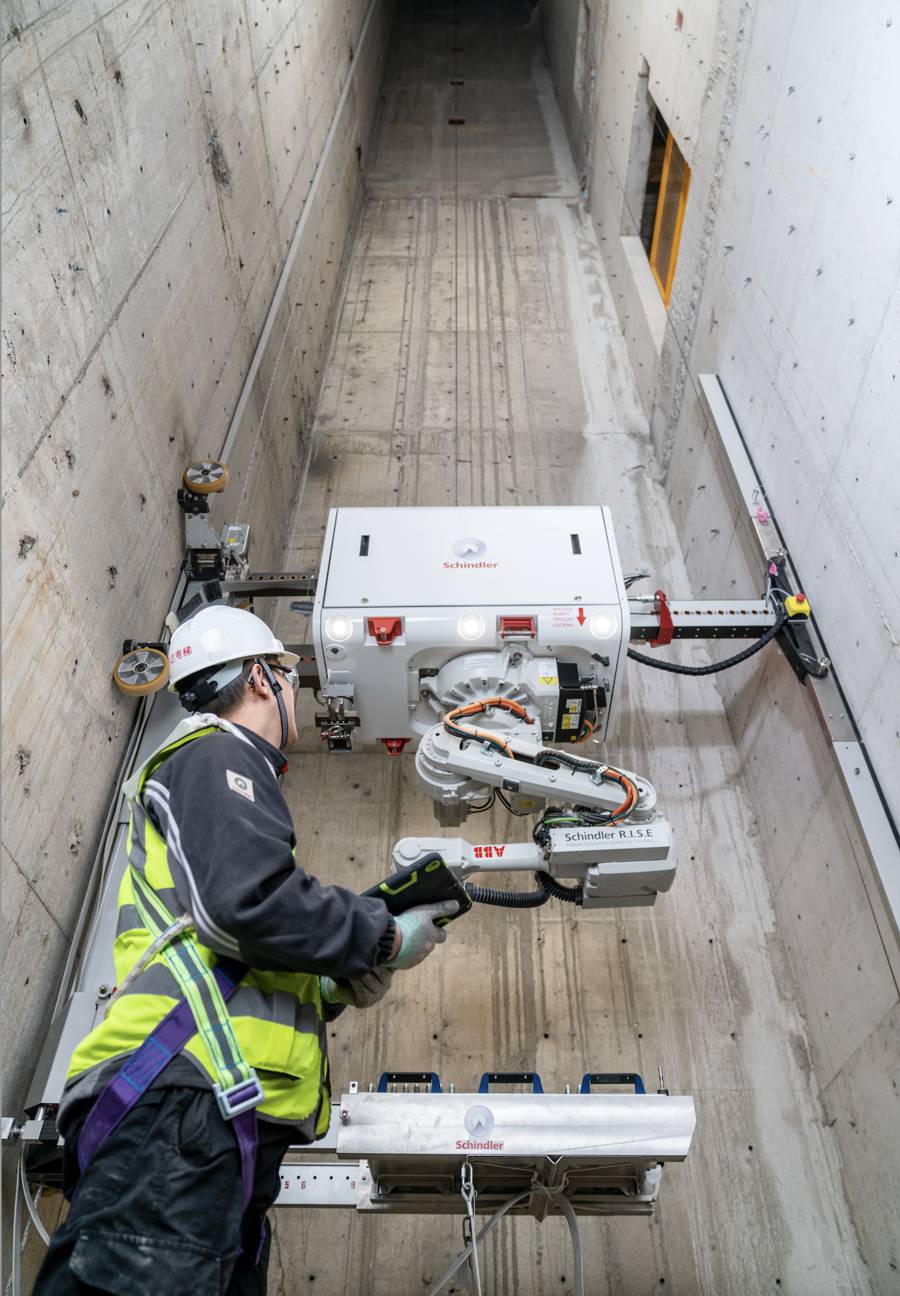

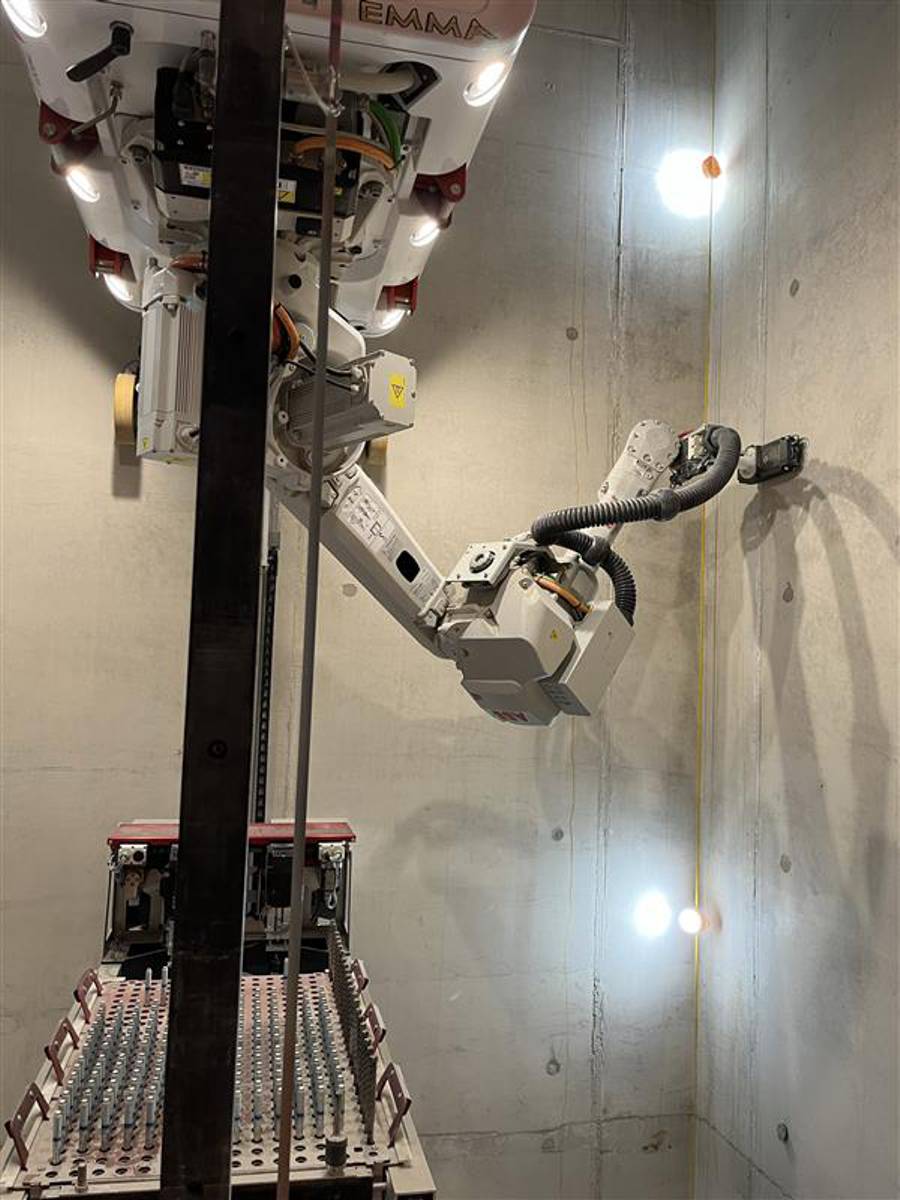

At its core, Schindler R.I.S.E is a self-climbing robot designed to navigate elevator shafts autonomously, executing what used to be arduous manual tasks with pinpoint accuracy. Armed with tools to drill holes and install anchor bolts, it handles the core of lift installation work without breaking a sweat—or producing one, for that matter.

Typically, these tasks involve long hours in hot, cramped shafts, with high dust levels and considerable safety risks. By contrast, Schindler R.I.S.E significantly reduces the need for human presence in these hostile environments. A single specialist operator monitors the robot remotely, ensuring both safety and efficiency are top-tier.

“Innovation and sustainability are at the heart of this new high-rise in London, so it makes sense for 105 Victoria Street to be the first in the UK to appoint Schindler R.I.S.E,” said Stuart Cross, Managing Director of Schindler UK & Ireland. “We’ve seen the advances in quality, speed and safety that the robots bring to projects around the world, and as automation becomes a bigger part of the construction process, it makes sense to utilise it at a building’s core.”

High-Tech Robot Meets Net Zero Vision

The robot isn’t working just anywhere. It’s part of one of the UK’s most ambitious sustainable office projects to date. Developed by BGO and built by Skanska, 105 Victoria Street will span 445,000 square feet when complete in 2026. Entirely electric and targeting net zero carbon, the development is being touted as a beacon for what future office buildings should strive to be.

Emma Foster, Principal at BGO, highlighted the project’s guiding principles: “Maximising sustainability, social value and wellbeing has been our guiding principle on the 105 Victoria Project. From the outset, we have sought to work with partners that are aligned with this commitment at every stage. We are thrilled to partner with Schindler and Skanska to bring this game-changing innovation to the UK for the first time, prioritising worker wellbeing and facilitating a safer, more efficient and forward-thinking construction industry.”

Schindler R.I.S.E fits right into that ethos. It not only speeds up installation times but also minimises errors, reduces material waste, and boosts worker safety—ticking all the boxes in terms of sustainable innovation.

Tech for Safety and Wellbeing

Skanska, the project’s main contractor, is no stranger to pioneering new approaches in construction. For Terry Muckian, Executive Vice President at Skanska, innovation is more than a buzzword.

“At Skanska, we believe that embracing advanced technologies like Schindler R.I.S.E is essential for pushing the boundaries of construction. By trialling these innovations, we can deliver projects with greater efficiency, safety, and quality,” he said. “Additionally, using this robot enhances safety during the elevator installation and minimises exposure to noisy, dusty environments, making our work sites a better place to be.”

With almost 600 skyscrapers in the UK’s planning pipeline, according to New London Architecture, all eyes will be on how Schindler R.I.S.E performs. If it lives up to its potential, this might just become the industry standard for high-rise elevator installations.

Elevating Sustainability at 105 Victoria Street

But it’s not just about robotics and automation. The building itself is a showcase of sustainable design from top to bottom.

105 Victoria Street is set to achieve WELL Platinum certification—no small feat. The WELL Building Standard evaluates spaces based on ten key factors, including:

- Air quality

- Water systems

- Lighting design

- Thermal comfort

- Acoustic control

- Material sustainability

- Mind and community well-being

The office floors boast a generous 3.5m floor-to-slab height, allowing natural light to flood in. Opening windows support a mixed-mode ventilation strategy, drastically cutting the need for mechanical cooling.

Projected energy use is slashed by 64% compared to traditional office buildings, with the clever design potentially eliminating the need for plant cooling for up to half the year.

Carbon Crunching and Urban Greening

One of the more impressive stats comes from the building’s carbon footprint. Predicted embodied carbon savings, when compared to the Stage 4 baseline, equal the carbon sequestration of around 151,600 trees over a 60-year span. That’s a massive stride towards true sustainability—focusing on actual reductions rather than carbon offsets.

The building’s green credentials go beyond the numbers:

- A 25,000 sq ft green space, including living green walls

- An on-site urban farm

- A rooftop garden and biodiversity-boosting landscaping

- Composting solutions for organic waste

These features not only boost local air quality and urban biodiversity but also offer tenants a healthier, more engaging workspace.

Beyond the Lift Shaft

With just five Schindler R.I.S.E units in existence worldwide, their deployment is currently reserved for high-profile, technically challenging projects. However, their success paves the way for broader adoption. Automation in construction isn’t just about flashy tech—it’s a route to safer, smarter, and more sustainable building practices.

The robot’s ability to work 24/7, follow precise instructions, and reduce physical strain on workers is something that traditional methods just can’t match. And while the up-front costs of deploying such tech might raise eyebrows, the long-term payoffs—in time, money, safety, and environmental impact—are already speaking volumes.

Setting a New Standard for Future Builds

With the UK racing to meet net zero goals and modernise its construction industry, 105 Victoria Street sets a powerful precedent. From green rooftops and energy-saving design to cutting-edge robotics, it demonstrates what’s possible when innovation and sustainability align.

Schindler R.I.S.E’s debut isn’t just a one-off gimmick—it’s a sign of things to come. As automation becomes more accessible and expected in large-scale projects, industry stakeholders will need to adapt or risk being left behind.

For now, all eyes are on the lift shaft at 105 Victoria Street. Because up there, above the dust and noise, the future’s already climbing.