Aquajet Unveils Game-Changing Hydrodemolition Robots at bauma

Aquajet, the Swedish powerhouse in Hydrodemolition technology, is preparing to shake up the concrete removal industry yet again. At bauma 2025 in Munich, from April 7-13, the company will unveil two eagerly anticipated machines: the Aqua Cutter 450A and Aqua Cutter 450V.

These electric-powered robots promise to deliver the hallmark precision and muscle of Aquajet’s larger machines, all packed into a leaner, more agile design.

“After launching the Aqua Cutter 750V and our game-changing Infinity oscillation system, the natural next step was to offer a more compact version,” said Roger Simonsson, Managing Director of Aquajet. “Our customers asked for a smaller alternative without compromising on efficiency — so we delivered. The 450 series is perfect for projects where size and agility are crucial, but performance remains a top priority.”

These compact marvels are ideal for urban worksites and restricted-access zones, boasting a surprising strength-to-size ratio. Despite their scaled-down footprint, the 450 series can handle reaction forces up to 1400N — a testament to Aquajet’s unwavering focus on durability and performance.

Evolution 3.0 and Infinity Oscillation

The 450A and 450V come loaded with Aquajet’s signature technologies. At the heart of both machines lies the advanced Evolution 3.0 control system, delivering unparalleled operator control and precision. Add to that the patented Infinity oscillation system, and you’ve got smooth, consistent nozzle movement that enhances both efficiency and surface finish.

Whether it’s descaling rebar or removing deteriorated concrete, these robots get the job done without causing microfractures, safeguarding structural integrity. And thanks to their compact size, they can reach spaces previously considered too tight for automated Hydrodemolition systems.

Designed for real-world challenges

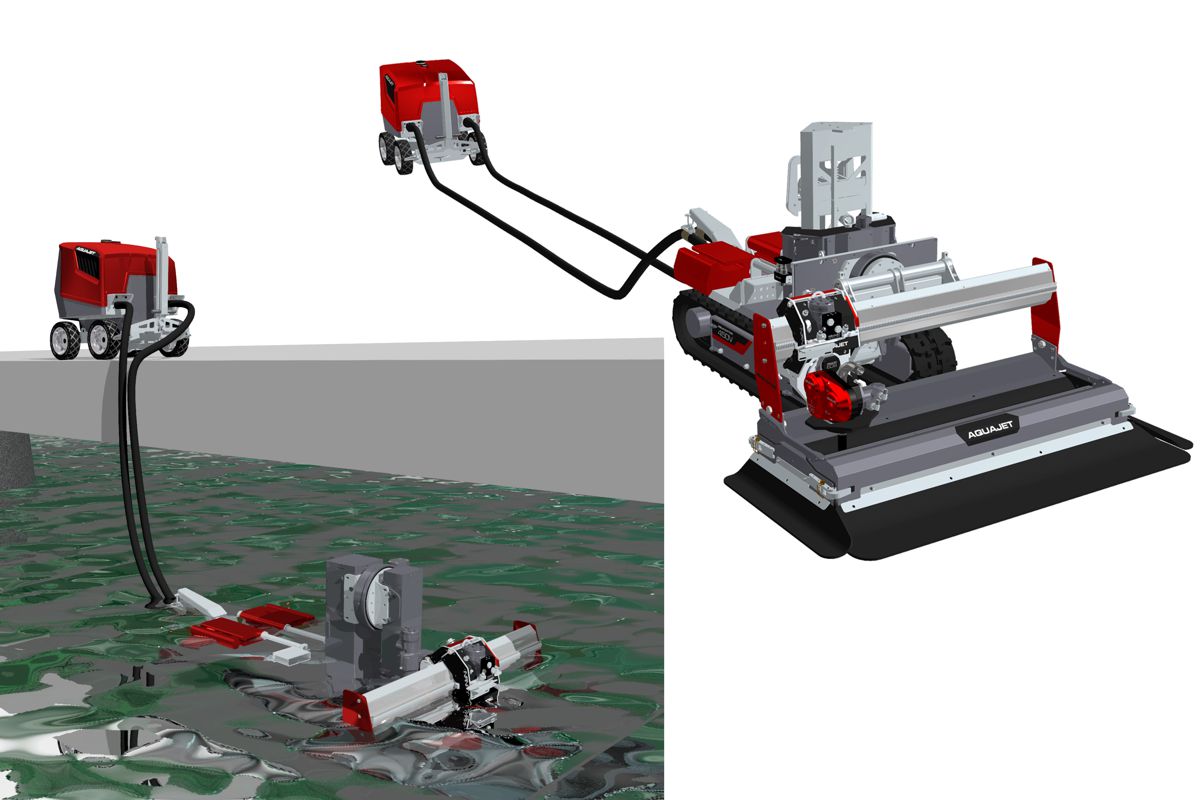

Aquajet clearly hasn’t built these robots just to show off engineering prowess; they’ve been designed for boots-on-the-ground practicality. A standout feature is the detachable Power Control Module (PCM). It can be separated from the tracked crawler, allowing the crawler to be radio-controlled into confined or hazardous environments while the PCM stays put in a secure location.

This is particularly useful in scenarios like:

- Navigating narrow sewer pipes

- Working within small tunnels or culverts

- Performing vertical or overhead demolition in limited-access areas

Both models are emission-free, thanks to their electric drive, making them a smart choice for urban and indoor projects where diesel emissions are a no-go.

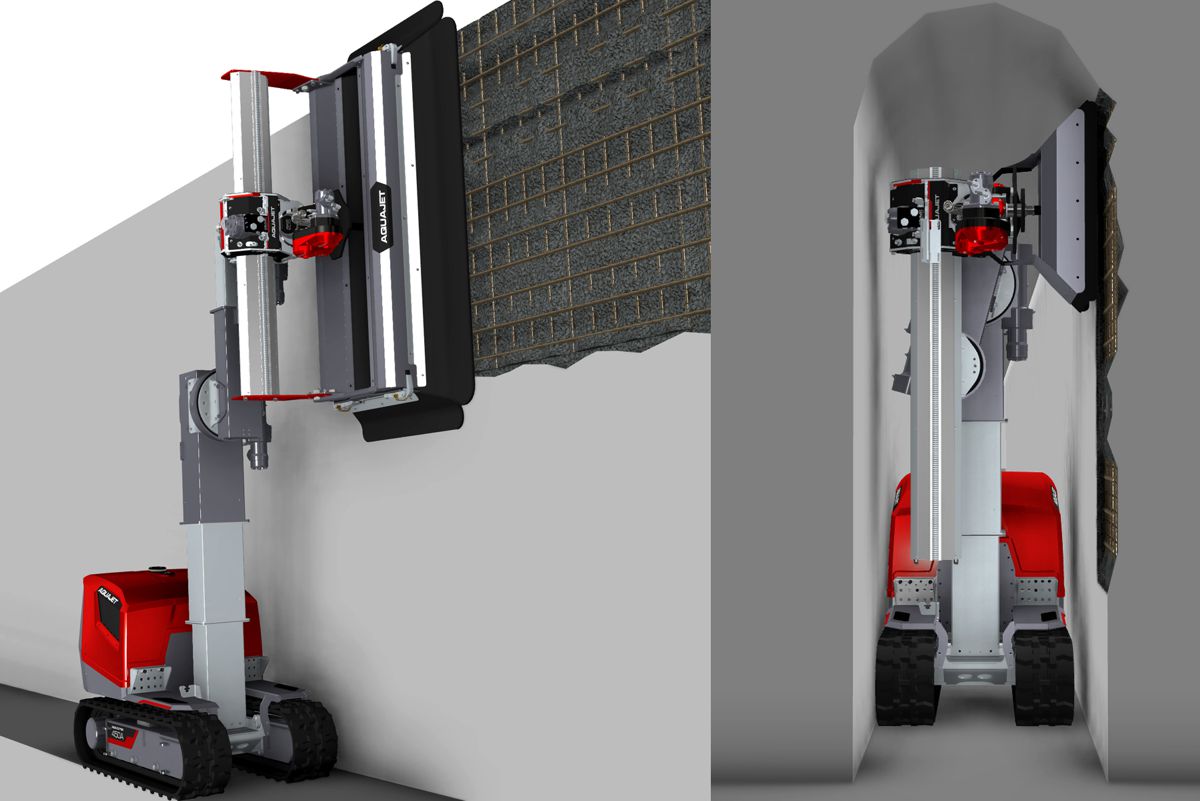

Built for tight quarters

The 450A shines when space is at a premium. With a hydraulic, articulated arm featuring two rotating joints and three telescopic extensions, it reaches up to 3 metres (9.8 ft). It’s tailor-made for tasks on narrow ledges, scaffoldings, or in tight passageways.

Operators will appreciate the 450A’s nimble design, which allows them to work in places that were previously the domain of manual labour or less effective tools. It’s compact, yes, but every inch is packed with capability.

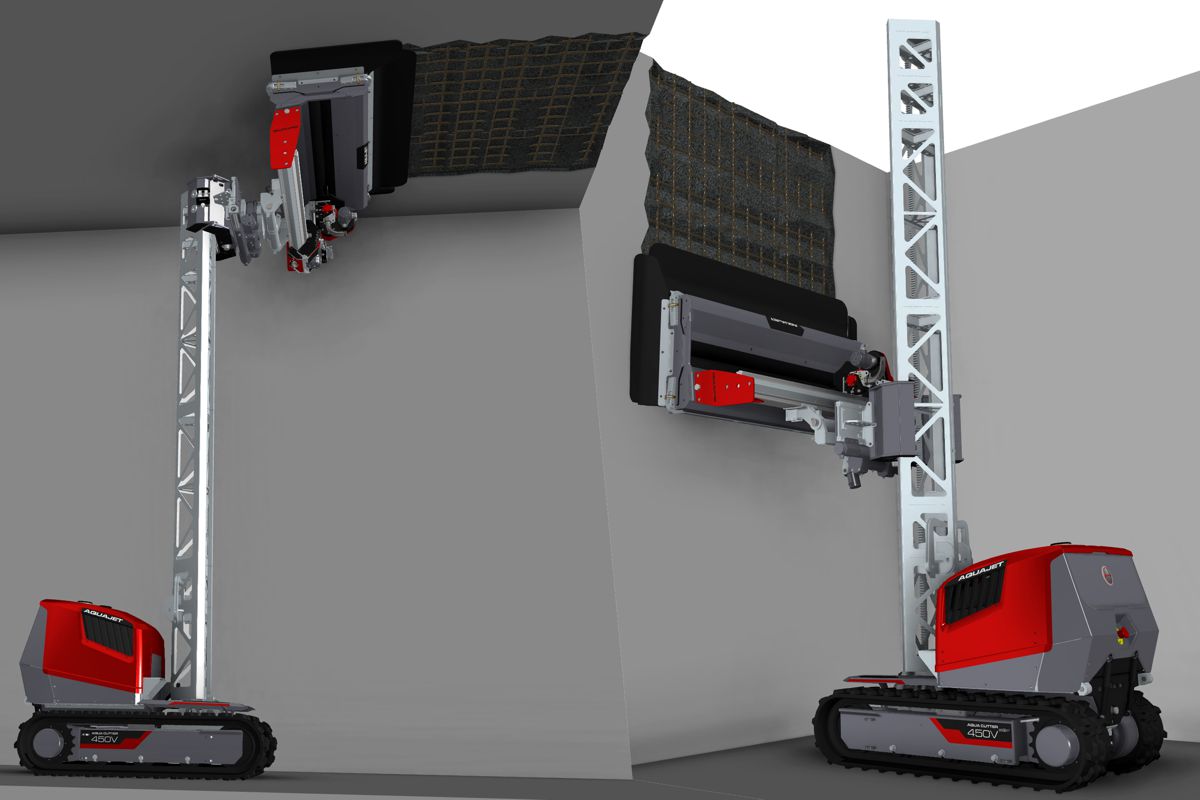

Reaching new heights

The 450V, meanwhile, takes a page from its bigger sibling, the Aqua Cutter 750V. Featuring a tower system that gives it a vertical reach of up to 4 metres (13.1 ft), the 450V is built for shaft work and vertical Hydrodemolition in spaces where manoeuvrability is non-negotiable.

It’s a best-of-both-worlds scenario: the compactness of the 450A combined with the reach of larger models, making the 450V the go-to choice for specialists dealing with challenging vertical applications.

Fully integrated, future-ready

Compatibility is another strong suit. Both models work seamlessly with Aquajet’s ecosystem of tools and accessories:

- Aqua Rail system for extended horizontal or overhead reach

- EcoClear system for on-site wastewater treatment and recirculation

- High-pressure pumps including the ultra-quiet Ecosilence

These integrations not only boost productivity but also ensure compliance with growing environmental and regulatory demands.

With EcoClear, for instance, operators can manage water responsibly and sustainably — a crucial consideration in modern infrastructure projects.

Meeting the industry’s growing demands

Hydrodemolition has rapidly grown into a preferred method for concrete removal due to its accuracy, speed and non-destructive nature. With cities becoming denser and environmental standards tightening, there’s a clear shift toward compact, electric-powered machinery.

Aquajet has responded not just with machines, but with meaningful innovation tailored to real-world job sites. Their acquisition by Brokk AB in 2016 only strengthened their global footprint and R&D capabilities, reinforcing their reputation as industry pioneers.

At bauma 2025, Aquajet’s Stand A1.325 will be the place to see these advancements first-hand. Industry professionals and decision-makers alike will be watching closely, and for good reason.

Raising the bar for Hydrodemolition

The Aqua Cutter 450A and 450V don’t just fill a gap in Aquajet’s product line — they redefine what’s possible in compact Hydrodemolition. By marrying high-end control systems, patented technologies, and emissions-free operation, Aquajet is proving that size really isn’t everything.

The future of Hydrodemolition is smaller, smarter, and more sustainable. And with these new compact giants, Aquajet is leading the charge.