Gripping the Future with Gecko-Inspired Adhesives for Robotic Handling

In the fast-evolving realm of robotics and material science, a quiet revolution is taking place, one that could reshape how machines interact with their environment. Engineers at Xi’an Jiaotong University in China have taken a bold step forward, introducing a new class of dry adhesive that doesn’t just mimic nature – it thinks like it.

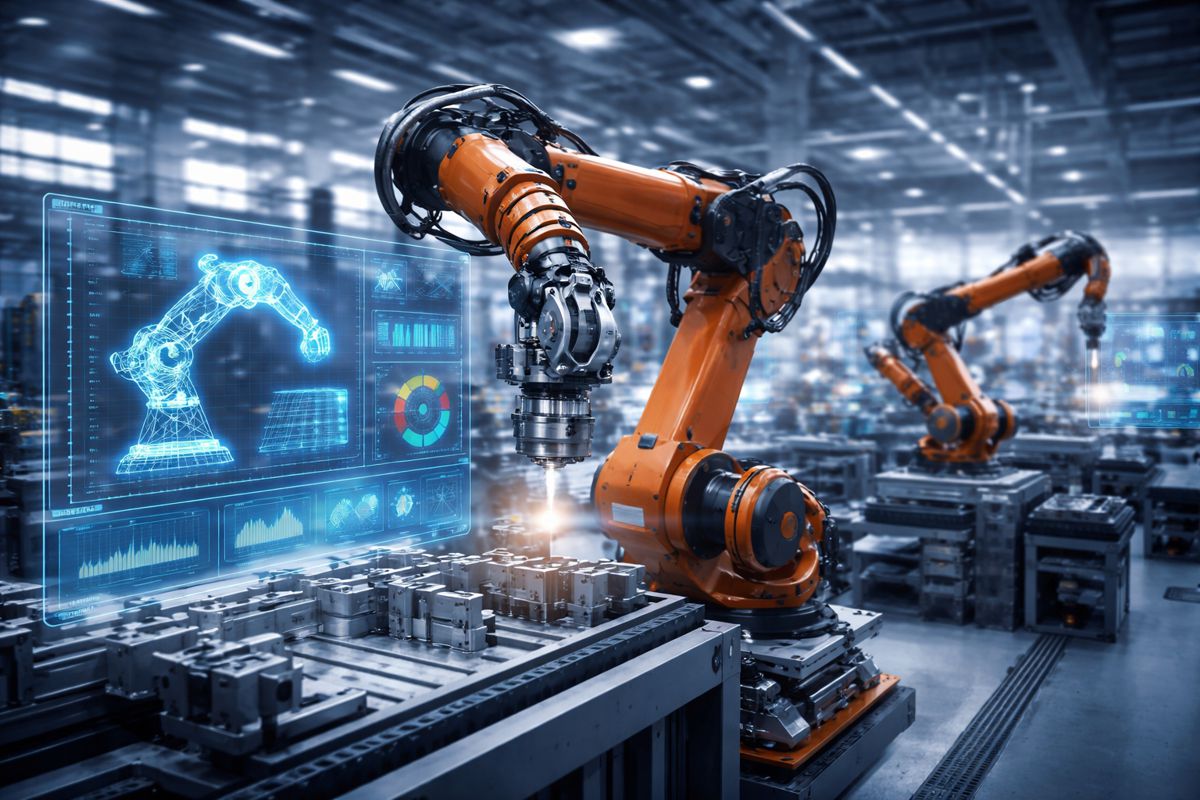

Their creation, a self-adaptive core-shell dry adhesive with a “live core,” stands out by tackling one of the stickiest issues in adhesion science: how to maintain a firm grip when the contact surfaces aren’t perfectly aligned. This breakthrough could transform everything from robotic grasping in industrial settings to delicate optical component assembly.

Why Traditional Adhesives Fall Short

Artificial dry adhesives inspired by gecko feet have long been a promising frontier. These lizard-like marvels owe their cling to van der Waals forces, which are exceptionally effective under perfect contact conditions. But, let’s face it, perfection is rare in real-world engineering.

Non-parallel contact—where surfaces meet at an angle—is more the norm than the exception. Unfortunately, conventional gecko-inspired adhesives often fail miserably here, with reduced grip strength and instability causing robotic arms to fumble, misalign or drop items altogether. For high-precision tasks and automated systems, that kind of unreliability just won’t cut it.

The “Live Core” Concept

Enter the self-adaptive core-shell dry adhesive. Borrowing from the anatomy of gecko soles—where soft muscle wraps around rigid bone—the researchers designed an adhesive that adapts dynamically to its contact environment.

At the heart of the innovation lies a mushroom-shaped adhesion tip sitting atop a clever core-shell structure. Unlike traditional designs where the core is rigidly fixed (often dubbed a “dead core”), this system features a mobile “live core” that can freely rotate within a soft shell. This motion is key, as it compensates for angular misalignments and evenly distributes stress across the adhesive interface.

“We wanted to engineer something that could adjust itself, just like your wrist adjusts when you grab a tilted object,” said lead researcher Duorui Wang. “The rotation of the live core mimics skeletal joints, making the adhesive flexible under misaligned conditions.”

Simplicity Meets Ingenuity

The team used common yet versatile materials like polydimethylsiloxane (PDMS) and silicone rubber to construct the adhesive. Despite their humble origins, these materials provided the perfect balance of flexibility and strength.

Through meticulous fabrication and testing, the researchers assessed not just how the adhesive performed under ideal conditions, but also under real-life scenarios. They examined its gripping power during both parallel and non-parallel contact situations, putting it through its paces with varying loads, temperatures, and even underwater.

The results were eye-opening. The adhesive delivered adhesion strengths up to 100 times greater than traditional homogeneous structures under misaligned conditions. That sort of performance isn’t just impressive—it’s revolutionary.

Digital Modelling Backed the Science

To complement their lab results, the researchers ran detailed Finite Element Analysis (FEA) simulations. These models demonstrated exactly how the rotating core reduced misalignment angles and rebalanced stress points.

“The FEA results confirmed what we saw in our experiments: the adhesive naturally adapted to non-parallel surfaces without losing grip,” explained co-author Jinyou Shao.

By visualising stress distributions and movement dynamics, the team was able to further refine the structure and tweak critical parameters such as the stiffness of the soft shell and the geometry of the rigid core.

Stability Under Pressure

One of the standout features of the new adhesive is its anti-overturning ability. In robotic grasping applications, especially where objects are heavy, oddly shaped, or placed at awkward angles, preventing overturning is crucial.

This adhesive keeps its grip where others would topple. Its ability to adapt to varied contact angles without compromising stability means robotic arms can operate more like human hands—quick, sure, and versatile.

Moreover, the adhesive maintained its properties across a range of environmental conditions. Whether exposed to heat or submerged in water, its performance barely flinched. That makes it a strong candidate for industries where conditions are anything but predictable.

Fine-Tuning for Maximum Effect

Beyond performance, the researchers delved into design optimisation. They explored how factors like core placement, shell softness, and overall geometry influence the adhesive’s rotation angle and grip strength.

Their goal: to build a toolkit for future developers and engineers who might customise the adhesive for niche applications. It’s not a one-size-fits-all solution but a platform technology, adaptable and scalable.

Real-World Applications and Future Horizons

So, where could this gecko-inspired adhesive really shine? The list is long and growing:

- Precision assembly: Particularly in optics and microelectronics, where a misaligned grip could spell disaster

- Robotic manufacturing: Especially in environments with irregular surfaces or fragile materials

- Medical robotics: Gripping soft tissue or instruments without slippage

- Underwater operations: Thanks to its resistance to water and temperature extremes

And that’s just scratching the surface. The self-adaptive core-shell concept could soon find its way into next-gen wearables, haptic feedback systems, and even space robotics.

“This is a foundational technology,” noted Hongmiao Tian, co-author of the study. “We’re not just solving a problem; we’re opening a new door to intelligent gripping systems.”

Gripping Potential

As robotics grows smarter, the demand for smarter materials follows suit. The self-adaptive core-shell adhesive from Xi’an Jiaotong University is more than just a novel idea—it’s a practical solution to a long-standing problem.

In a world where automation is key and perfection is rare, having a material that can think on its feet (or tips) is worth its weight in gold.