Smarter Manufacturing Through Data-Model Fusion

In today’s high-speed, high-stakes industrial world, manufacturers and engineers are no longer satisfied with guesswork or siloed systems. They’re after precision, agility, and insight—all rolled into one seamless operation.

That’s exactly where Data-Model Fusion (DMF) steps in, offering a clever blend of physics-based models and data-driven intelligence to revolutionise smart manufacturing and digital engineering.

Bridging Two Worlds

Traditionally, engineers have leaned on two primary methodologies: model-based and data-driven. The model-based camp depends on mathematical equations rooted in physics and engineering know-how. Think fluid dynamics, thermodynamics, or material science. While grounded in science, these models often struggle with computational intensity and real-world complexity.

On the flip side, data-driven techniques rely purely on algorithms mining massive datasets. Machine learning, neural networks, and statistical models offer fast insights, but they often lack transparency and can trip over irrelevant or redundant inputs.

Here’s the rub: neither approach is perfect in isolation. Enter DMF.

Data-Model Fusion is all about synergy. By combining the rigour of traditional modelling with the adaptability of modern data science, DMF delivers smarter systems that are both explainable and effective.

Fei Tao, co-author of the recent review paper, put it simply: “DMF integrates model-based and data-driven approaches to minimise the weaknesses of each while maximising their strengths.”

A Framework for Fusion

The research team, led by Fei Tao and colleagues Yilin Li, Yupeng Wei, Chenyuan Zhang, and Ying Zuo, has mapped out a clear framework for how this fusion works. Their paper, published in Engineering, breaks DMF down into four distinct levels:

- Data-Level Fusion: Merges raw data with model inputs to ensure completeness.

- Feature-Level Fusion: Aligns selected data features with model parameters.

- Method-Level Fusion: Integrates data processing and model computation methods.

- Decision-Level Fusion: Combines outputs to improve decision accuracy.

This layered structure allows for tailored integration depending on the task at hand, whether it’s monitoring a production line or predicting the failure of a turbine blade.

Boosting the Product Lifecycle

DMF isn’t just a backroom theory. It’s already making waves across the entire product lifecycle:

1. Smarter Product Design

Designers often rely on simulations to test how a new product might perform under stress or in different environments. But simulations alone can be computationally expensive and time-consuming.

DMF helps by incorporating surrogate models and hybrid simulations that balance fidelity with speed. This means engineers can run more iterations, explore more variables, and optimise designs without melting their processors.

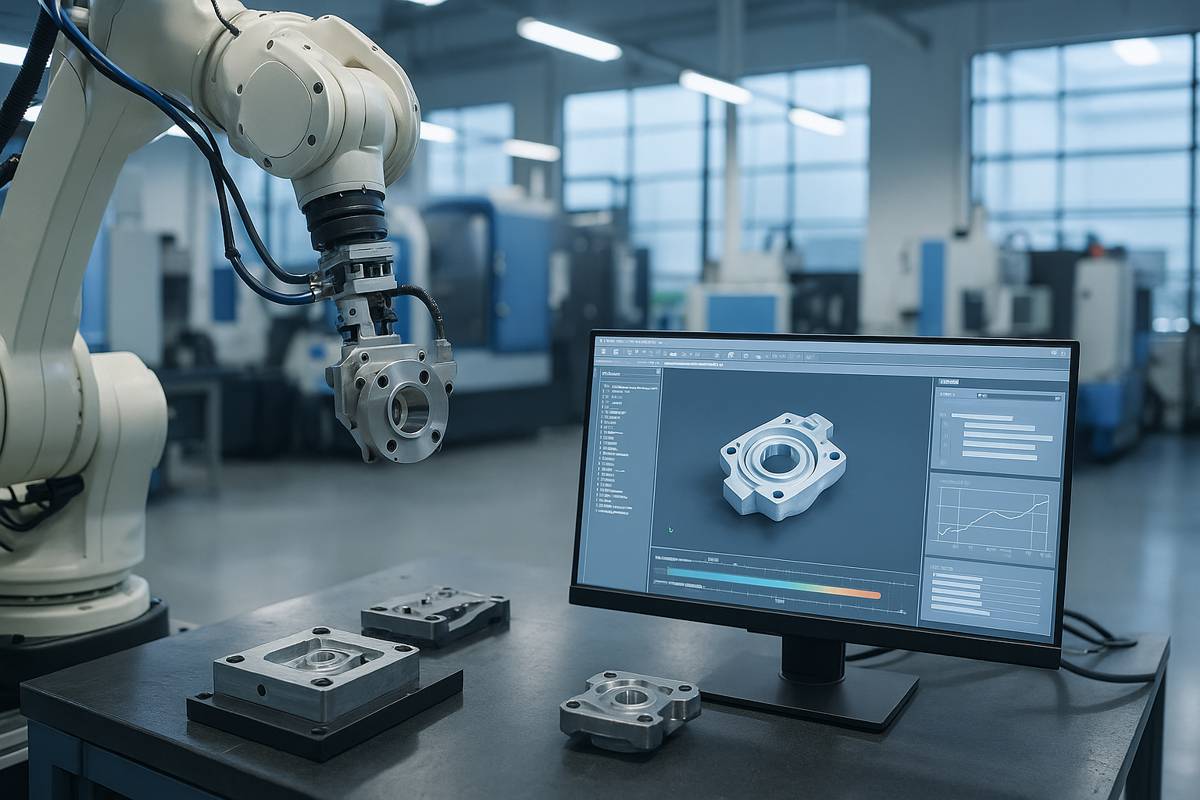

2. Precision in Manufacturing

Manufacturing processes are notoriously complex and dynamic. Temperature, pressure, humidity, machine wear – they all affect output quality. DMF supports real-time process control by linking sensor data with predictive models.

For example, a CNC machine could adjust its cutting speed based on both historical data trends and live thermal feedback. That means tighter tolerances, less waste, and improved overall equipment effectiveness (OEE).

3. Intelligent Testing and Verification

Experimentation, testing, and verification (ETV) can eat up both time and budget. Here, DMF uses hybrid models to simulate test scenarios before they even occur.

Instead of running dozens of expensive physical tests, manufacturers can predict likely outcomes and identify which scenarios truly warrant validation. That streamlining doesn’t just cut costs—it boosts speed to market.

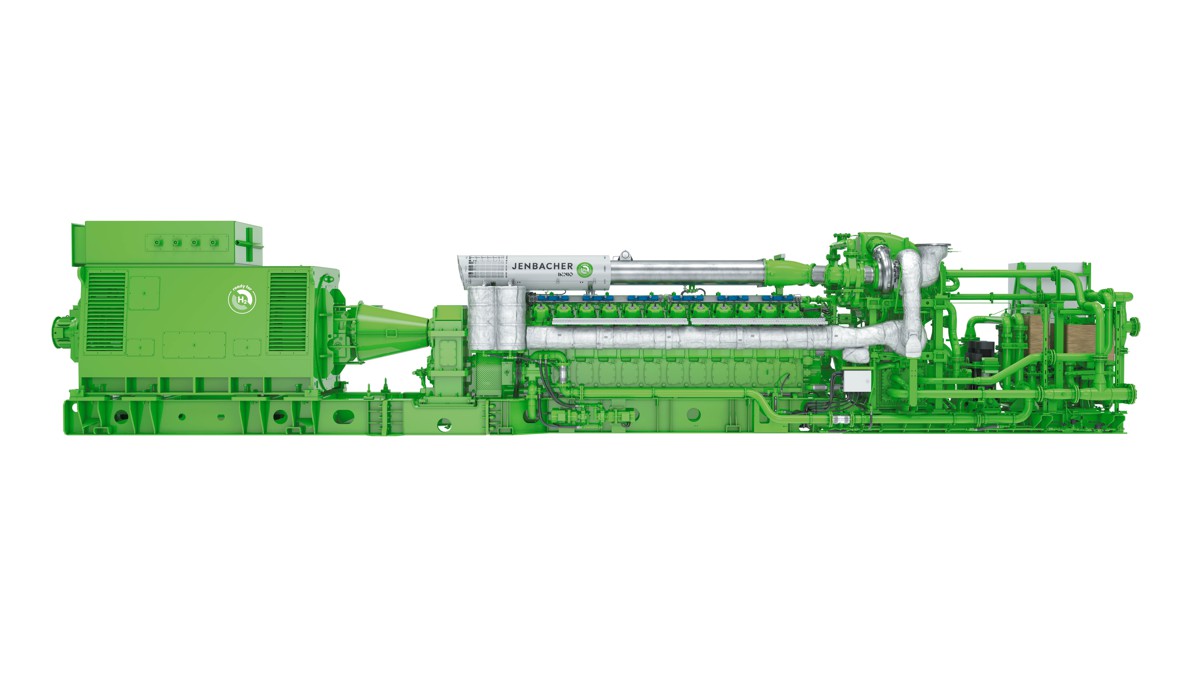

4. Predictive Maintenance with Clarity

In maintenance, timing is everything. Too early, and it’s a waste. Too late, and it’s disaster. DMF bridges the gap by turning raw diagnostic data into interpretable insights.

As the authors note: “By fusing data-driven predictions with physical degradation models, maintenance decisions become both data-informed and scientifically grounded.”

The result? More accurate forecasts, less unplanned downtime, and a maintenance strategy that makes sense to both technicians and CFOs.

Looking to the Future

DMF is still in its relative infancy, but the path ahead is paved with promise. As digital engineering and digital twins become foundational technologies, DMF will serve as the bridge connecting them to real-world manufacturing.

The rise of edge-cloud collaboration will further supercharge its adoption. Computation-heavy tasks can be distributed between local edge devices and central cloud servers, ensuring efficiency without sacrificing latency.

And with generative AI tools like large language models entering the fray, the human-machine interface will only get smarter. Imagine AI-assisted model tuning or voice-controlled design adjustments based on real-time data streams.

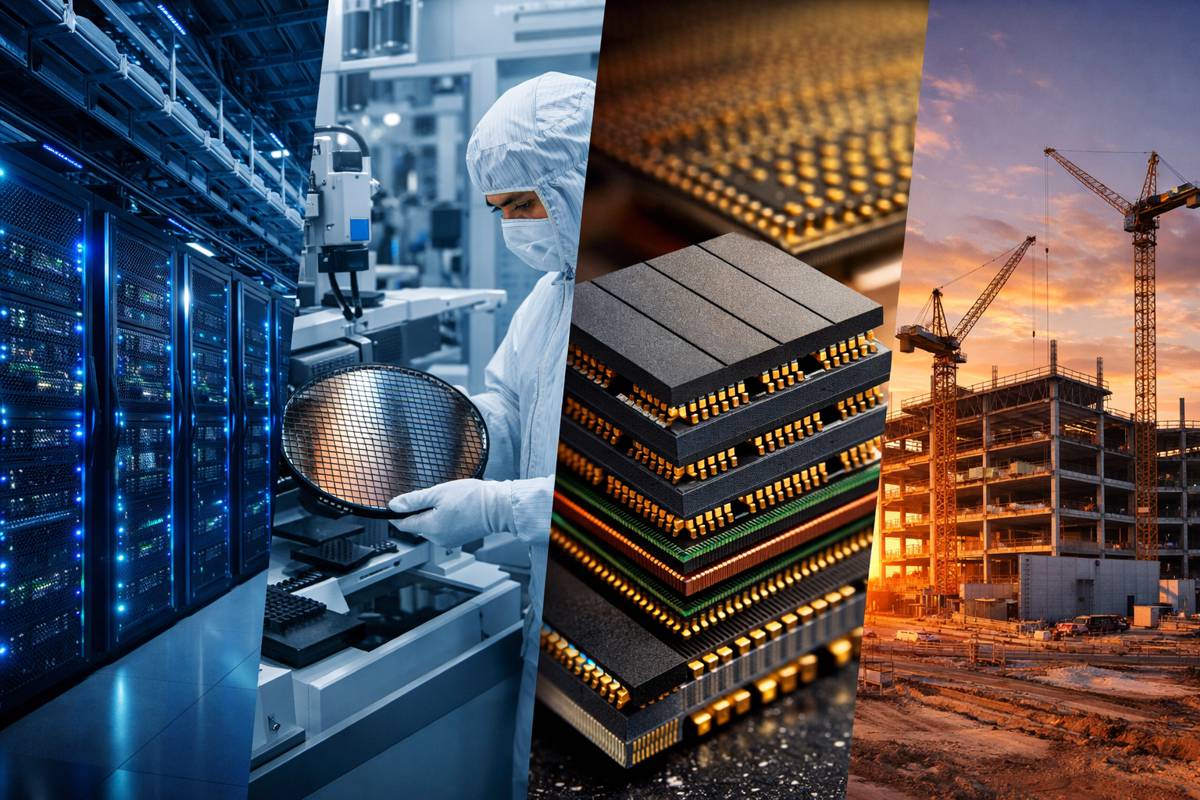

Beyond the factory floor, there’s growing interest in how DMF can support:

- Manufacturing-as-a-Service (MaaS)

- Virtual testing platforms for regulatory compliance

- Supply chain simulation and risk mitigation

The potential applications span aerospace, automotive, electronics, and beyond.

A Leap Forward for Industry

There’s no doubt that DMF represents a powerful shift in how industries approach engineering challenges. By weaving together the analytical strength of models with the contextual intelligence of data, businesses can unlock insights that were previously out of reach.

This isn’t just about efficiency. It’s about resilience, adaptability, and future-proofing in a world where standing still simply isn’t an option.

As Fei Tao and his co-authors concluded: “Data-model fusion will not only reshape smart manufacturing but also guide the digital evolution of engineering itself.”

Gearing Up for Transformation

The takeaway for policymakers, manufacturers, and investors is crystal clear: now’s the time to explore DMF.

Whether through pilot projects, academic collaborations, or tech partnerships, embracing this fusion approach could very well be the secret sauce for next-gen innovation.