Cutting Errors in Electrical Estimating with AI

Even the most seasoned electrical contractors can stumble when it comes to estimating. Whether it’s an overlooked circuit, an incorrect device count, or a missed spec in the drawings, minor mistakes often snowball into costly problems. That’s where modern electrical estimating software steps in, offering a digital safety net that minimizes risk and enhances precision.

One such tool leading the change is Drawer AI, designed specifically to help estimators detect, review, and correct potential oversights before they ever reach the job site. By automating tedious tasks and providing a bird’s-eye view of every plan set, these platforms act as a force multiplier for both junior and senior estimators alike.

Let’s explore how artificial intelligence is reshaping accuracy standards in electrical estimating – and why your team should take notice.

The Cost of Estimating Errors

Errors in electrical bids can range from mildly inconvenient to project-crippling. Common mistakes include:

- Incomplete takeoffs

- Incorrect material counts

- Misread specifications

- Skipped QA/QC steps

Each misstep can affect profit margins, jobsite coordination, or even client trust.

According to industry estimates, a 1% error on a multimillion-dollar project can result in tens of thousands in lost revenue.

The need for accuracy is clear – and AI can help fill the gaps that human estimators, no matter how experienced, sometimes leave.

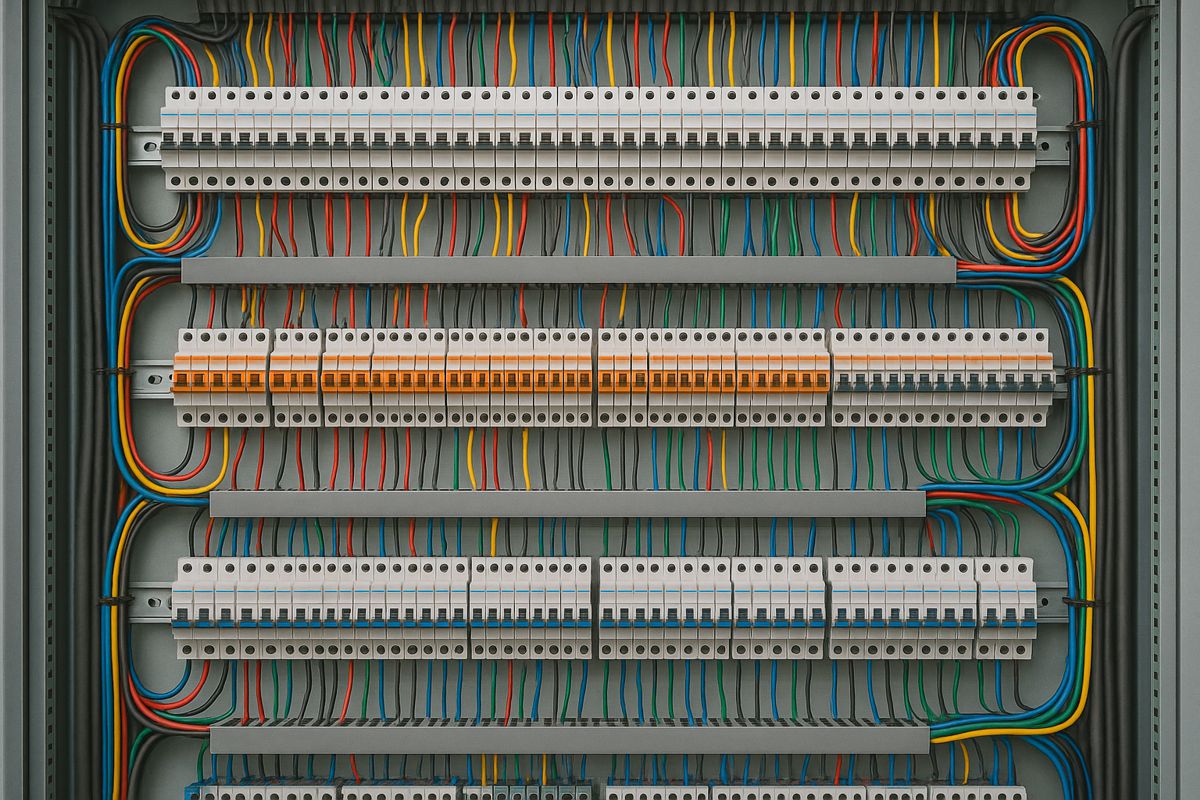

AI’s Role in Reviewing Drawings

One of the most time-consuming phases of estimating is reading and interpreting electrical drawings. These documents are dense, multi-layered, and often difficult to navigate.

AI-enhanced platforms automate this process by:

- Scanning vector-based PDFs instead of relying on pixel-based pattern matching

- Automatically identifying devices, fixtures, and panels

- Parsing schedules and legends for embedded information

Instead of spending hours deciphering layout sheets, estimators receive pre-populated counts and routing previews – leaving them free to validate or tweak results as needed.

From Manual Takeoffs to Machine Learning

Manual takeoffs require extreme attention to detail and are notoriously vulnerable to:

- Fatigue

- Inconsistent measurement tools

- Human oversight

Even digital tools without AI can still fall short, as they typically rely on click-based inputs. AI-driven platforms, however, learn from previous estimates, detect anomalies, and even recognize where certain elements should exist based on historical project data.

| Method | Risk of Error | Speed | Learning Capability |

| Manual Takeoff | High | Slow | None |

| Standard Software | Medium | Medium | Low |

| AI Estimating Tool | Low | Fast | High |

As more data flows through these systems, accuracy continues to improve – making AI a long-term investment in estimating efficiency.

Built-In QA and Error Detection

Another major advantage of AI is its quality assurance (QA) toolkit. With every takeoff or spec comparison, tools like Drawer AI highlight potential red flags, such as:

- Unusually short or long conduit runs

- Incomplete device groupings

- Missing panel callouts

This allows estimators to catch errors early, reducing the need for change orders or RFIs downstream. AI doesn’t just process data – it scrutinizes it.

Real-World Routing and Labor Consideration

Estimating labor isn’t just about device count. Routing complexity, building type, and access constraints all play a role.

AI tools model real-world routing paths by analyzing:

- Panel location

- Obstruction points

- Typical conduit lengths based on building type

Estimators can toggle between ideal paths and realistic ones, helping them account for labor intensity and time commitment.

Streamlined Specification Review

Specifications are dense and nuanced – a single missed requirement can dramatically change your pricing.

AI parses these documents for key phrases and anomalies, highlighting:

- Specialty material requirements

- Installation methods

- Code references

This cross-checking ensures you don’t miss high-impact details like tamper-resistant outlets or stainless-steel conduits.

Consistency Across Teams

Even in the best-run organizations, estimator outputs can vary widely. AI brings a layer of consistency that makes results easier to compare and validate across departments.

Instead of retraining staff for each project, teams work within a repeatable digital framework that improves over time.

With AI in the loop, junior estimators perform more like veterans – speeding up onboarding and improving scalability.

How AI Helps During Bid Reviews

In fast-paced bid environments, mistakes happen due to crunch-time pressure. AI helps reduce last-minute scrambling by:

- Offering real-time device counts

- Generating audit trails for takeoff decisions

- Highlighting gaps or redundancies in scope

This not only shortens timelines but also strengthens your position when negotiating with general contractors or justifying change orders.

Winning More Work, Smarter

The benefits of AI go beyond error prevention. By enhancing accuracy, contractors can submit more competitive bids without sacrificing margins. This ultimately improves win rates and long-term profitability.

| Benefit | Impact on Projects |

| Fewer Mistakes | Less rework, fewer disputes |

| Faster Turnarounds | More bids submitted on time |

| Consistent Documentation | Easier QA/QC and audits |

| Better Forecasting | Smarter procurement and staffing |

In a market where every edge counts, AI becomes more than a tool – it’s a strategic asset.

Final Thoughts

Accuracy is everything in electrical estimating. A few errors might be inevitable in manual workflows, but modern AI tools have changed the game. With digital tools like Drawer AI, estimators can work faster, smarter, and more confidently – delivering polished bids that align with real-world execution.

This article will be used for a guest post to acquire backlinks, not for publication on Drawer website blog. It is part of the link building process. Article is generated using AI tools