High-Speed Centrifugal Blowers in Refineries and Power Plants

Centrifugal blowers are widely used in a variety of industries, including vacuum, smelting blast furnaces, coal washeries, mine flotation, sewage treatment, and special gas transportation.

High efficiency, low noise, smooth operation, no pulse, large stable area, clean, dry, and oil-free gas, less vulnerable parts, and ease of installation, operation, and maintenance are some of the features of this blower series.

An apparatus that moves air or other gases perpendicular to its axis of rotation is called a centrifugal fan. High speed centrifugal blowers fans, sometimes known as blowers, blower fans, or squirrel-cage fans (because they resemble hamster wheels), frequently have a ducted housing to direct outgoing air in a particular direction or across a heat sink. They are frequently referred to as biscuit blowers and are employed in computers. These fans transfer air from their revolving input to their outlet. Usually, they are employed in ducted applications to push air through comparable impellers or draw air through ductwork or heat exchangers. Centrifugal Blowers or fans propel the air stream against resistance from ducts, dampers, and other parts by using the kinetic energy of the impellers.

When compared to positive-displacement blowers, centrifugal fans offer both advantages and disadvantages. These include the fact that centrifugal fans are more efficient, while positive-displacement blowers may be less expensive to purchase.

Building

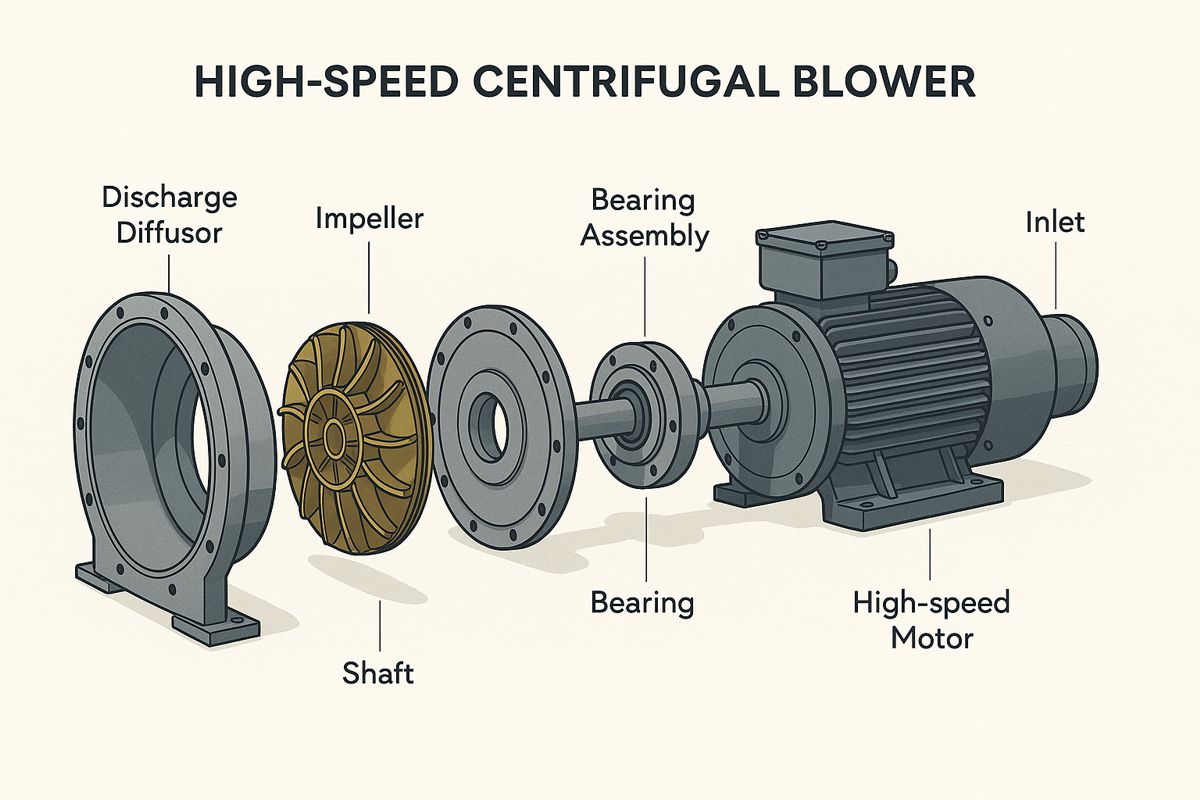

A centrifugal fan’s primary components are:

- Housing for fans

- Impellers

- Ducts for inlets and outlets

- The drive shaft

- The drive mechanism

- Vanes and Fan Dampers

- Ducts for inlets and outlets

- Blades of fans

- casing for fan discharge

Bearings, couplings, shaft seal plates, fan discharge casings, impeller locking devices, and other parts might be utilized.

Drive systems

The fan drive controls the fan wheel’s (impeller’s) speed and how much it can be adjusted. Fan drives come in two main varieties.

Straightforward

An electric motor’s shaft can be directly connected to the fan wheel. This indicates that the motor’s rotational speed and the fan wheel speed are the same. Since there are no losses while transferring the motor’s rotating speed to the fan’s, direct drive is the most efficient type of fan drive.

Centrifugal fans with external rotor motors—the rotor is mounted directly on the fan wheel (impeller) and the stator is inside the rotor—have been produced by some electronics manufacturers.

Belt

A set of sheaves is mounted on the motor shaft and the fan wheel shaft, and a belt conveys the mechanical energy from the motor to the fan. The ratio of the motor sheave’s diameter to the fan wheel sheave’s diameter determines the fan wheel speed. Unless the belt or belts slide, fan wheel speeds in belt-driven fans are set. The fan wheel speed can be lowered by several hundred revolutions per minute (RPM) due to belt slippage [20]. Belts also add another maintenance item.

Bearings

A fan’s bearings are a crucial component. Ball bearings are used in larger residential and commercial applications, while sleeve-ring bearings are utilized in smaller fans, such computer fans. Specialized bearings, like water-cooled sleeve bearings for hot gas exhaustion, may be utilized in industrial applications.

Both air and magnetic bearings are used in many turbo blowers.

Low transmitted vibration, high-speed levitation, low power consumption, excellent dependability, oil-free operation, and resistance to air stream particle pollutants are all features of magnetic bearing blowers.

Conclusion

if you want to move a lot of air and are searching for a centrifugal air blower. These devices are typically used to transport large volumes of air in constrained areas. Their spinning blades boost the amount of air that passes through them and supply kinetic energy.

These devices work by drawing in a lot of air that is contained within the shell of the blower. A hover is created as a result, and it is then pulled through the blades. Saturated or dry air both function well with the centrifugal air blower. Its impeller is made of corrosion-resistant metals to withstand the air’s moisture content.

Additionally, these devices have anti-rust coatings installed. This suggests spending less on maintenance.