The Best In Situ Construction Methods for a Lunar Future

As humanity inches closer to establishing a permanent presence beyond Earth, the focus of lunar exploration is shifting from short-term visits to long-term settlement. This evolution makes in situ lunar construction not just an option, but a necessity.

By using the Moon’s own resources—chiefly its regolith—scientists and engineers aim to reduce the enormous costs of transporting building materials from Earth while creating robust infrastructure that can endure the lunar environment.

The challenge is straightforward in concept yet complex in execution: how do we transform the Moon’s dusty surface material into safe, durable structures? This question lies at the heart of research led by Professor Feng of Tsinghua University, whose team has meticulously analysed and categorised nearly 20 different regolith solidification and formation techniques.

Understanding Lunar Regolith Techniques

Professor Feng’s study divides regolith processing into four main categories, each based on the way particles bond and cohere:

- Reaction Solidification (RS) – Regolith particles are chemically bonded using compounds, usually brought from Earth. Local material makes up between 60% and 95% of the final product.

- Sintering/Melting (SM) – Involves heating regolith above 1,000°C until it fuses. This can use 100% lunar material but demands high energy input and robust equipment.

- Bonding Solidification (BS) – Binders adhere particles at lower temperatures, with a 65% to 95% in situ ratio.

- Confinement Formation (CF) – Regolith is packed into fabric containers, forming components without inter-particle bonding. This boasts an in situ ratio of up to 99% and requires minimal processing.

Each method offers unique advantages and drawbacks, influencing its suitability for different phases of lunar base construction.

The 8IMEM Evaluation System

To move from theory to application, Professor Feng’s team created the 8IMEM system—an evaluation framework with eight criteria tailored to lunar construction priorities. These include:

- Resource consumption

- Energy requirements

- Equipment needs

- Formation speed

- Structural strength

- Durability in lunar conditions

- Scalability

- Operational complexity

Using this system, the team ranked the techniques, revealing some clear leaders.

Regolith Bagging

At the top of the rankings is regolith bagging—a method within the confinement formation category. It excels by demanding minimal materials, simple equipment, and low energy. It also enables rapid production of large components. “Regolith bagging emerged as the highest-rated technique for large-scale in situ lunar construction,” notes the research.

While the tensile strength of these components is high, they may require reinforcement for compressive loads. This makes them ideal for certain structural applications, particularly in the early stages of lunar base construction.

Other High-Performing Techniques

Sintering and melting processes also rank highly, offering strong structural integrity, especially when solar energy is harnessed for melting. “Solar melting offers a path towards low-energy construction,” the study points out, underlining the potential of renewable energy use on the Moon.

Casting techniques, though more resource-intensive, stand out for producing components with exceptional curing strength. This could make them indispensable for critical load-bearing elements in later phases of base development.

A Four-Stage Lunar Development Plan

The research outlines a practical roadmap for lunar base evolution:

- Laboratory Stage – Supporting unmanned science missions.

- Research Station Stage – Hosting temporary astronaut crews.

- Residence Stage – Providing long-term accommodation akin to a space station.

- Habitat Stage – A self-sustaining settlement and a launch point for deeper space missions.

For each stage, regolith bag technology is proposed as the foundational construction method, supplemented by other techniques as requirements grow more complex.

Additional Insights from Global Research

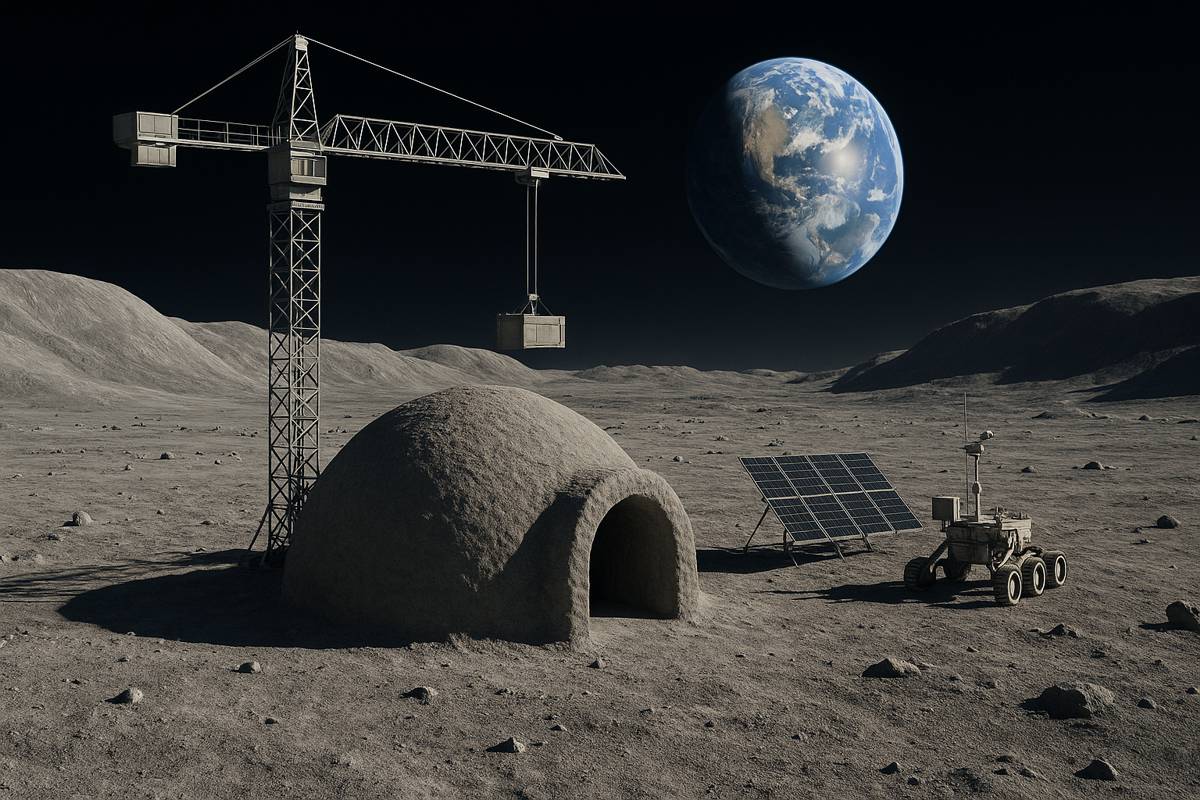

Beyond Professor Feng’s work, other agencies such as NASA and ESA have explored regolith-based 3D printing and microwave sintering. NASA’s “Lunar Lantern” project, for example, investigates building roads and landing pads using focused sunlight to melt regolith, while ESA’s partnership with Foster + Partners has experimented with dome-shaped habitats printed from lunar simulants.

These complementary efforts reinforce the idea that no single technique will dominate. Instead, a hybrid approach will likely be key, combining the rapid scalability of regolith bagging with the strength and precision of sintering and casting.

Preparing for Lunar Challenges

Any lunar construction method must address hazards such as micrometeorite impacts, extreme temperature swings, and radiation exposure. Regolith itself offers natural shielding from radiation, making thick-walled structures highly desirable.

Another challenge is automation. The Moon’s early construction projects will rely heavily on autonomous or remotely operated systems due to the high cost and risk of human labour in such a hostile environment. Designing machinery that can operate reliably in low gravity and fine dust conditions will be critical.

A Vision for the Future

By grounding their recommendations in quantitative analysis, Professor Feng’s team provides a valuable blueprint for turning lunar construction from a conceptual ambition into a practical reality. Their work suggests that the first human habitats on the Moon could be built with minimal imports from Earth, relying primarily on the Moon itself to shelter its new inhabitants.

“The proposed lunar habitat design based on regolith bags serves as a practical reference for future missions,” the research concludes, offering a tangible step toward a sustainable human presence on the Moon.

Towards a Sustainable Lunar Presence

As the world edges closer to a new era of space exploration, the vision of self-sufficient lunar settlements is moving out of the realm of science fiction.

By leveraging local materials, minimising resource transport, and integrating renewable energy solutions, we could soon see the Moon not just as a distant destination, but as humanity’s second home.