Cracking the Code of Surface Topography

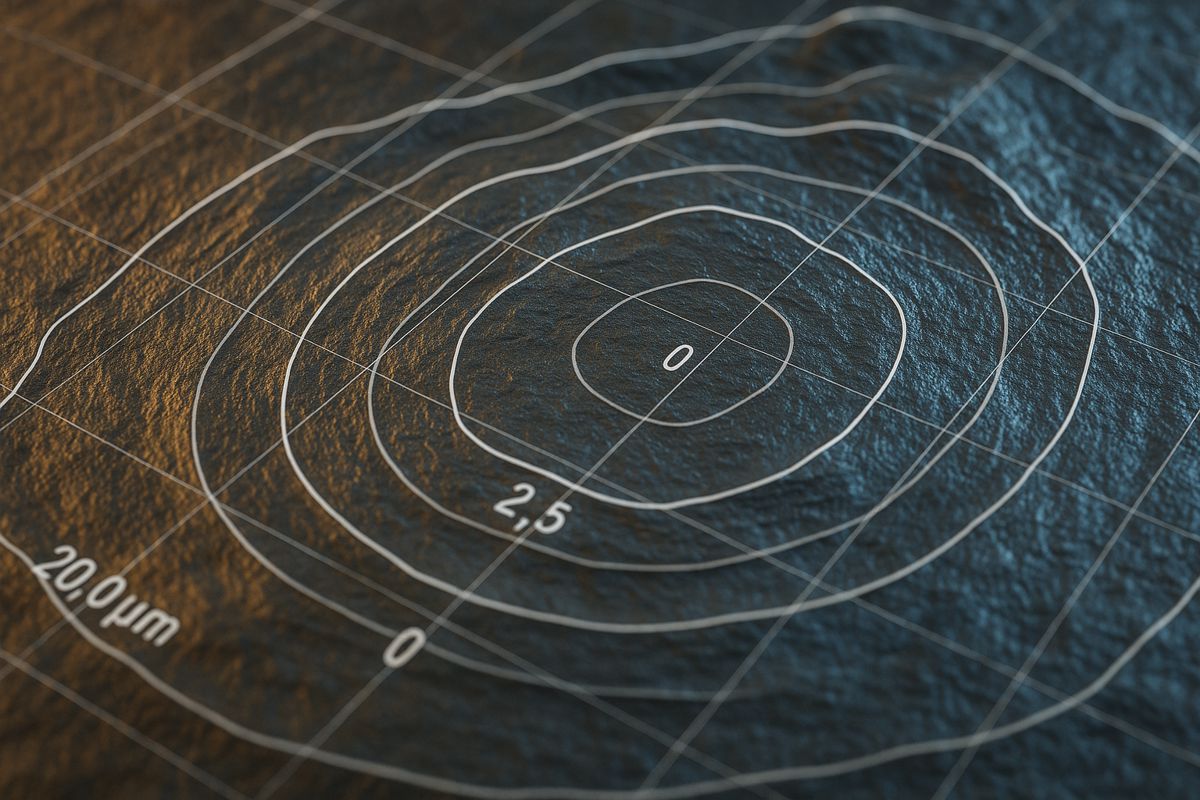

Anyone who has slipped on a gleaming marble floor or battled for traction on an icy road understands that surfaces matter. In manufacturing, whether it’s crafting high-performance running shoes, precision-engineered robotics, or semiconductor chips, surface characteristics can make or break performance. Yet, despite their importance, the methods for measuring and describing surface topography remain inconsistent and often incomplete.

Recognising this gap, a team of researchers from the University of Pittsburgh, University of Freiburg, and Saarland University have launched a global initiative to address the challenge. Led by Tevis Jacobs, Lars Pastewka, and Martin Müser, alongside graduate researcher Arushi Pradhan, the Surface-Topography Challenge is an ambitious bid to better define, measure, and standardise how surfaces are characterised.

The findings have been published in Tribology Letters under the title The Surface-Topography Challenge: A multi-laboratory benchmark study to advance the characterization of topography.

Why roughness matters

Professor Tevis Jacobs, a mechanical engineering and materials science specialist at the University of Pittsburgh, studies the performance of surfaces in applications ranging from slip-and-fall accident prevention to medical devices and semiconductor manufacturing. His work focuses on how adhesion, friction, and wear are influenced by surface roughness.

“Roughness matters down to the nanometre scale,” Jacobs explained. In robotics, for instance, a warehouse gripper’s ability to handle fragile items relies on understanding topography at multiple scales. Yet no single measurement method can fully capture a surface’s complexity.

Lars Pastewka, a professor in the Department of Microsystems Engineering at the University of Freiburg, elaborated: “The industry-standard methods for measuring and characterising roughness work well in certain cases, but they are limited in the information they contain and the predictive power they can provide.”

In scientific research, non-standard metrics are often preferred for greater precision, but the diversity of available tools, techniques, and models can lead to wildly different interpretations.

Jacobs likens it to the parable of the blind men and the elephant: “Each researcher measures a different aspect of the surface, but variations in techniques and scale result in dramatically different pictures of the same object.”

From modelling to reality

The inspiration for the challenge came from Müser’s 2015 Contact-Mechanics Challenge, where participants analysed a computer-generated surface using any theories or models they chose. The results offered valuable insight into modelling roughness, but Jacobs and Pastewka saw an opportunity to take it further by working with real-world surfaces.

At a 2022 Gordon Research Conference, they announced the Surface-Topography Challenge. Using semiconductor fabrication techniques, the team produced two chromium nitride-coated surfaces—one smooth, one rough—and distributed them to willing participants around the globe.

Participants were free to use any measurement tools or techniques they preferred, uploading their raw data to a shared repository. Expectations for modest engagement were quickly surpassed—more than 150 researchers from 64 groups across 20 countries submitted a remarkable 2,088 individual measurements.

Müser reflected: “Seeing such a large number of participants in the Surface-Topography Challenge reflects the widespread interest in advancing our understanding of topography and how we can best measure it.”

A wealth of data, and a few surprises

Pastewka emphasised the project’s significance: “The simulation community has made tremendous advances in predicting the performance of rough surfaces, but these advances have had limited applicability because of a lack of comprehensive measurement of topography for real-world surfaces. Now, with so many measurements of these two surfaces, we are gaining practical insights about how best to apply theory in real manufacturing.”

Graduate researcher Arushi Pradhan played a pivotal role, processing the data and uncovering key insights. The results revealed staggering variation: in one case, measurements of RMS height differed by a factor of one million between participants.

Pradhan noted: “The data revealed just how difficult it is to reach consensus about a surface topography. We had to correct for inconsistencies, artefacts, and resolution limits while deciding which techniques to include or exclude. But with all these measurements, we could reach a truer topography.”

Lessons for industry

While Jacobs acknowledges that manufacturers may not be able to replicate the exhaustive methods used in the challenge, he stresses a critical takeaway: using multiple measurement scales and techniques—even just two or three—can deliver significantly more accurate results.

“This surface-topography challenge wasn’t just for a few researchers; it’s for anyone who cares about surface performance,” Jacobs said. “Our ultimate goal is to find the right topography metrics—which can be used across research, product development, and quality assurance—to measure, control, and improve surface performance.”

The team continues to distribute benchmark samples to interested researchers, enabling ongoing collaboration and progress in refining measurement methods.

The road ahead

Jacobs is clear that the work is far from done: “Surface topography is critical to performance, but it’s not solved yet. This challenge is just the beginning.” As industries from aerospace to biomedical engineering push the boundaries of what’s possible, understanding and standardising surface measurement could become a decisive competitive advantage.

By creating a common framework and encouraging global collaboration, the Surface-Topography Challenge has already taken a vital step towards unlocking the full potential of surface science.