Ancient Weaving Inspires Next-Gen Metamaterials for Robotics and Engineering

Engineers at the University of Michigan have turned to a 7,500-year-old craft for inspiration, creating woven metamaterials that combine resilience and stiffness in ways previously thought impossible.

This breakthrough could shape the future of robotics, automotive engineering, architectural design, and beyond.

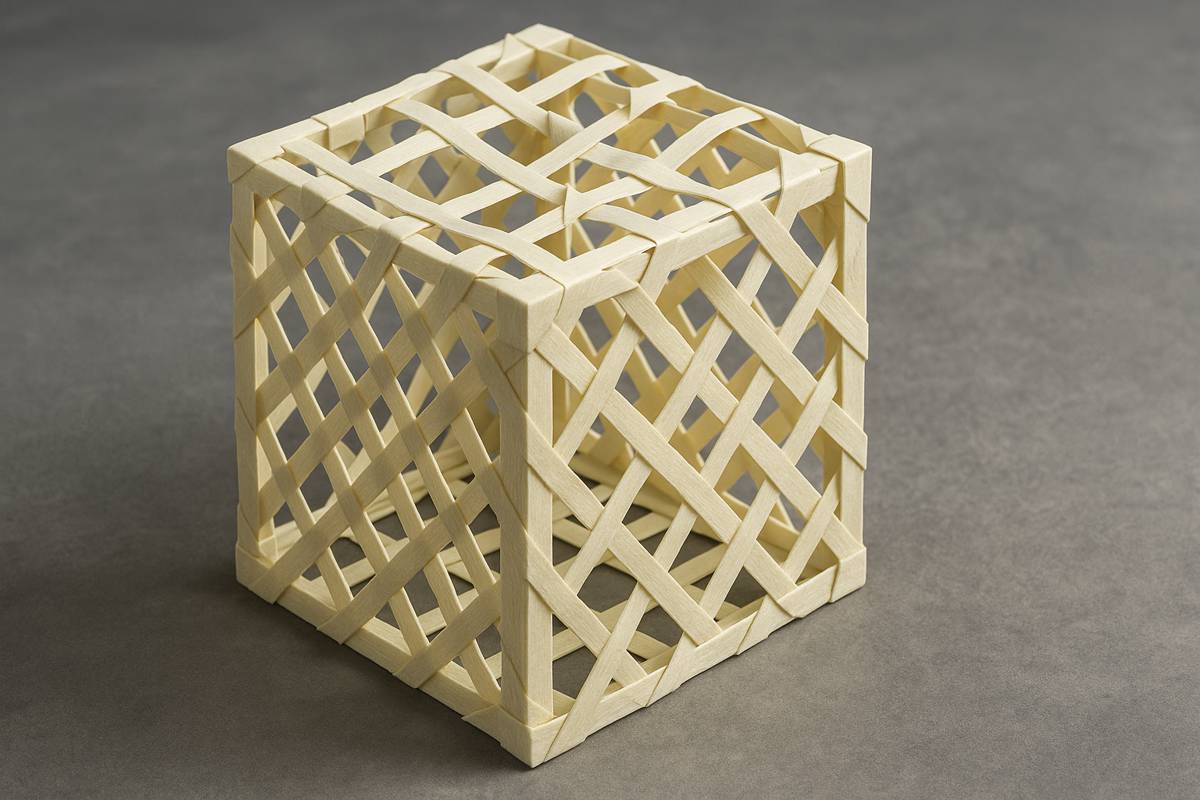

The research, recently published in Physical Review Research, reveals how basket-style weaving techniques can produce materials that bounce back to their original form after repeated heavy compressions, outperforming continuous sheet materials that tend to buckle and deform permanently.

Rediscovering mechanical advantages in ancient craft

Lead author Guowei (Wayne) Tu, a doctoral student in civil and environmental engineering, first stumbled upon the idea after reading about ancient woven baskets dated to around 7500 BCE. That prompted the team to ask whether weaving endured through history for more than just its geometry and beauty.

Evgueni Filipov, associate professor of civil and environmental engineering and mechanical engineering at U-M, explained: “We knew weaving is an effective way of creating 3D shapes from ribbons like reed and bark, but we suspected there must also be underlying mechanical advantages.”

Supported by the U.S. Air Force Office of Scientific Research, the study confirmed that woven metamaterials deliver both high stiffness for load-bearing and the resilience needed for long-term use.

Filipov added: “I’m very excited about harnessing the benefits of ancient basket weaving for modern 21st century engineering applications. For instance, lightweight woven materials for robotics would also help humans stay safer in case of human-robot collisions.”

How weaving transforms mechanical performance

The team crafted structures from Mylar polyester ribbons, each about the width of a finger and the thickness of two sheets of copy paper. Arranged in perpendicular weaves, these ribbons were formed into 3D metamaterials—synthetic composites whose structural patterns create unique physical properties.

Tu pointed out: “While modern metamaterials are often designed for electromagnetic, optical or acoustic properties, people have been making mechanical metamaterials through weaving and other structural approaches for millennia.”

Four different corner arrangements were tested, ranging from three to six intersecting planes. The same configurations were also made using continuous, unwoven Mylar for comparison. The results were striking. Woven structures survived compressions to less than 20% of their original height without damage, whereas continuous sheets buckled and deformed after far less strain.

High-resolution 3D scans revealed the reason: continuous sheets experienced concentrated stress points that caused buckling, while woven systems redistributed that stress across a larger area, preventing permanent damage.

Disproving the flexibility myth

The experiments also measured stiffness—how much force was required to compress or bend the structures. Contrary to the belief that woven systems are inherently flexible, the woven Mylar proved to be around 70% as stiff as continuous sheets. This balance of rigidity and adaptability makes them ideal for engineering scenarios where both qualities are needed.

One of the standout demonstrations was an L-shaped woven structure mimicking a robot arm. It could hold 80 times its own weight vertically yet still flex upward like a human arm. A woven four-legged robot prototype supported 25 times its weight, walked freely, and returned to shape even after being overloaded.

Tu explained: “With these few fundamental corner-shaped modules, we can design and easily fabricate woven surfaces and structural systems that have complex spatial geometries and are both stiff and resilient.”

Applications from robotics to architecture

The potential applications span multiple industries:

- Soft robotics: Woven designs could produce lightweight yet strong frames that remain safe for human interaction.

- Automotive engineering: Parts could be both rigid and impact-absorbent, enhancing vehicle safety.

- Architectural components: Structures could withstand environmental stresses without permanent deformation.

- Exoskeletons: Adaptive stiffness could support human movement while absorbing shocks.

The team has already developed a concept for a woven exoskeleton, with variable stiffness tailored to different parts of the human body, combining movement freedom with reusable shock protection.

Towards smart woven systems

Looking ahead, Filipov envisions merging these woven structures with active electronic materials: “Going forward, we want to integrate active electronic materials into these woven structures so they can be ‘smart’ systems that can sense the external environment and morph their shapes in response to different application scenarios.”

The implications extend well beyond robotics and vehicles. By adapting an ancient technique, engineers are opening doors to sustainable, reusable, and versatile material designs that could redefine modern manufacturing and structural engineering.

Weaving the past into the future

This marriage of prehistoric craftsmanship and cutting-edge materials science demonstrates that innovation doesn’t always mean reinventing the wheel—it can also mean rethinking ancient wisdom.

As industries push for stronger, lighter, and more sustainable solutions, the humble weave might just prove to be one of the most powerful tools in modern engineering.