Sharpening the Future of Machining with Advanced Edge Preparation Techniques

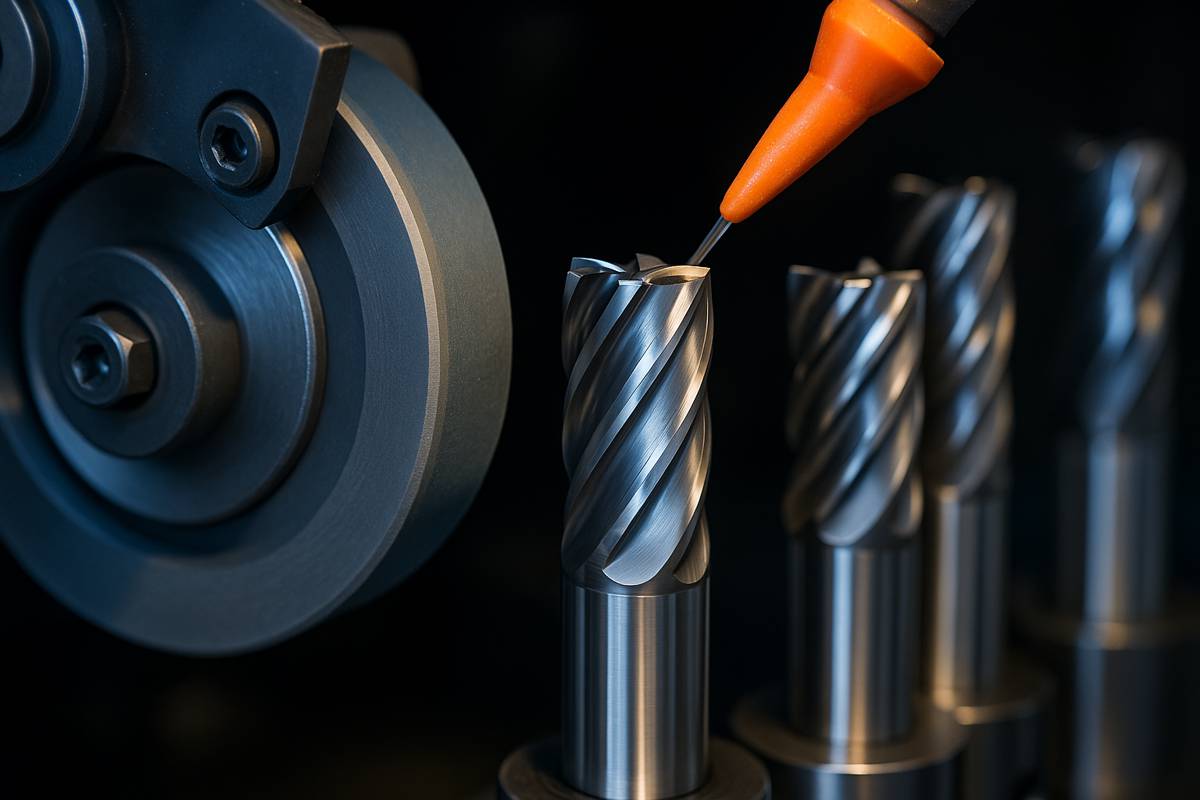

In the realm of mechanical engineering, the performance of cutting tools can make or break a machining operation. As manufacturing embraces ultraprecision cutting, high-speed machining, and dry processing of tough materials, expectations for cutting tool quality have never been higher.

Yet, despite technological strides, microscopic defects like burrs, chippings, and grinding marks still creep into cutting edges during production. Left unchecked, these imperfections trigger stress concentrations, speed up wear, reduce tool life, and compromise the finish of machined parts.

That’s where edge preparation comes into play. This critical process removes defects, fine-tunes edge geometry, and optimises cutting performance. A recent comprehensive review titled Edge preparation methods for cutting tools: a review sheds light on the state-of-the-art, offering both a technical roadmap and practical guidance for the industry.

Understanding Edge Characterisation

Before diving into preparation methods, it’s important to understand how cutting edges are characterised. Edge geometry directly influences tool behaviour under load, so precise measurement is essential. The study identifies three common edge profiles:

- Sharp edges – offering minimal resistance but prone to chipping.

- Chamfer edges – measured by chamfer length and the rake face angle, offering enhanced strength.

- Round edges – assessed using single-edge radius, form-factor (K-factor), and other advanced fitting techniques, improving edge durability.

Matching the right edge shape to the intended application is crucial for balancing sharpness, durability, and cutting stability.

Mechanical Processing Methods (MPMs)

Mechanical processing remains the backbone of edge preparation thanks to its practicality, cost-effectiveness, and adaptability. These methods physically remove material from the cutting edge, using controlled abrasion or contact. Key techniques include:

- Grinding – Employing grinding wheels to reshape and refine edges.

- Brushing – Using abrasive brushes to gently remove surface defects.

- Drag finishing – Rotating tools in abrasive media with a two-stage planetary motion.

- Abrasive jet machining – Directing high-velocity abrasive streams at the edge.

- Abrasive flow machining – Forcing abrasive-laden fluid across tool surfaces.

- Vibration machining – Applying oscillating forces to enhance material removal.

- Shear thickening polishing – Utilising non-Newtonian fluids to deliver uniform polishing.

Among these, brushing, drag finishing, and abrasive jet machining are favoured for high-volume production due to scalability. However, their processing quality can lag behind precision-driven applications.

Shear thickening polishing, on the other hand, shows remarkable promise, combining excellent edge consistency with superior surface finish.

Non-traditional Processing Methods (NPMs)

Non-traditional techniques bypass purely mechanical abrasion in favour of alternative energy sources such as lasers, electricity, and magnetic fields. These methods enable unique edge modifications but come with their own challenges:

- Magnetic abrasive machining – Harnessing magnetic fields to manipulate abrasive particles for controlled material removal.

- Laser machining – Melting or vaporising material with precision laser beams.

- Electrochemical machining – Using electrolysis to dissolve edge material without mechanical contact.

- Electrical discharge machining (EDM) – Employing spark erosion for precise edge shaping.

While these methods can achieve exceptional precision, some (especially laser and EDM) risk inducing thermal or microstructural damage at the cutting edge.

Magnetic abrasive machining stands out for its gentle yet controlled approach, minimising damage while achieving high consistency.

Comparing Methods

The review makes it clear: there’s no one-size-fits-all solution. Mechanical methods typically win on cost and ease of use, while non-traditional methods excel in fine control and customisation. However, the choice often comes down to the material being machined, the cutting tool substrate, and the production volume.

For example, in carbide tools used for high-speed steel cutting, chamfer or rounded edges created via brushing or drag finishing may suffice. But for aerospace-grade composites or hardened steels, a combination of magnetic abrasive machining and shear thickening polishing could deliver the best results.

Real-World Applications and Industry Impact

Edge preparation doesn’t just extend tool life – it also boosts productivity and surface quality, reduces downtime for tool changes, and cuts operational costs. Industries such as aerospace, automotive, and die manufacturing increasingly see edge preparation as a strategic investment rather than a finishing step.

Advances in automation are also driving change. Robotic edge preparation systems, equipped with adaptive feedback loops, can now tailor edge profiles in real-time based on wear data, pushing tool performance closer to its theoretical limit.

Innovation on the Horizon

As digital manufacturing matures, the integration of AI-driven inspection with edge preparation is likely to redefine the field. Machine vision systems can already detect microscopic defects, but coupling these with automated correction processes could eliminate manual intervention entirely. Additionally, hybrid methods combining mechanical and nontraditional approaches may emerge as the gold standard for high-performance tools.

The authors conclude: “Selecting the right edge preparation method based on tool material, geometry, and application can significantly improve machining efficiency, reduce costs, and enhance industry competitiveness.”

Driving Performance Through Precision

Cutting tool manufacturers now have more edge preparation options than ever before. The challenge lies in making informed choices that align with production goals, material constraints, and cost targets.

By leveraging both traditional and emerging techniques, manufacturers can unlock new levels of precision, durability, and efficiency in machining.