Revolutionising Functionally Graded Materials with Laser Remelting

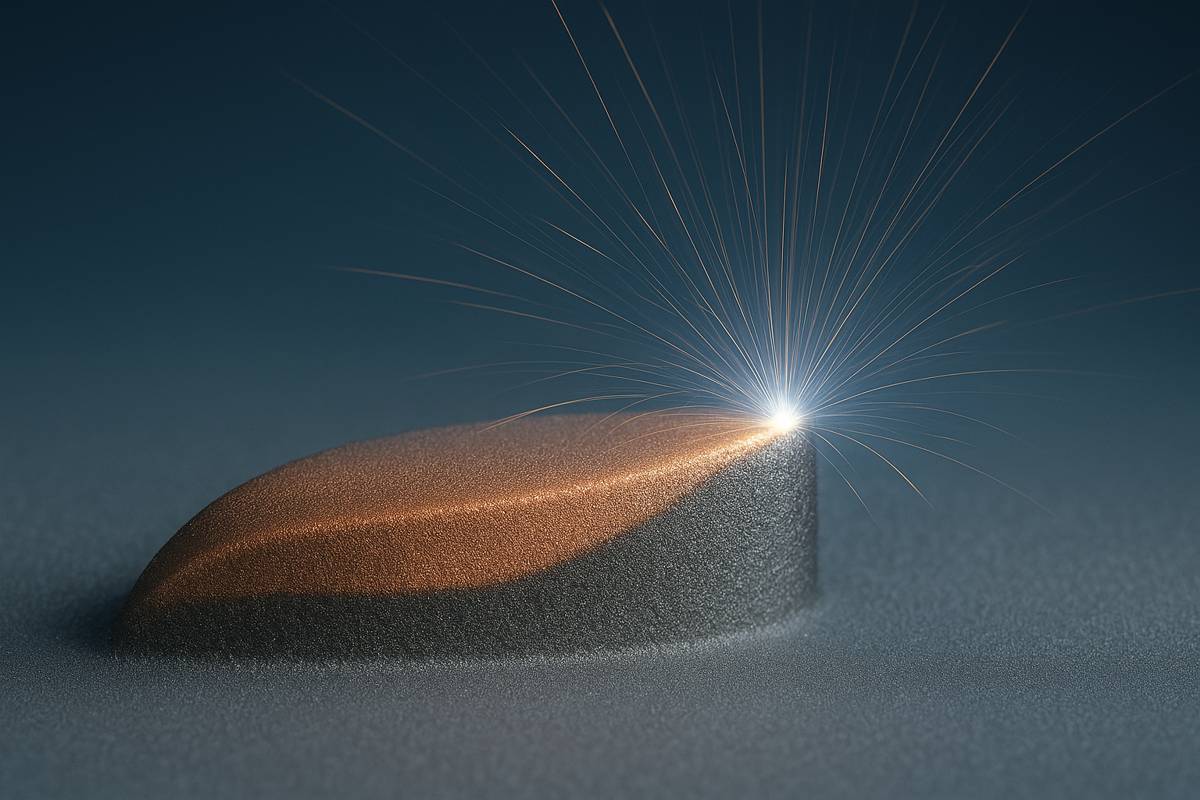

An international team of researchers has just spotlighted a clever fix for a longstanding additive manufacturing issue—achieving seamless transitions between dissimilar materials.

By weaving in a layer-wise laser remelting (LR) step within Laser Powder Bed Fusion (L‑PBF), they’ve tackled the stubborn problem of poor material mixing in functionally graded materials (FGMs). Here’s what makes this advance such a game‑changer for industries like aerospace and automotive.

The challenge of standard FGMs in MMAM

Functionally graded materials are prized for blending different properties through a controlled shift in composition, microstructure, or thermal behaviour—curved gradients, not abrupt changes. Traditional manufacturing routes such as casting, thermal spraying, or diffusion bonding often can’t shape complex forms economically, and they struggle to deliver truly smooth transitions.

Even in modern multi‑material additive manufacturing (MMAM) via L‑PBF, poor in‑situ mixing can leave jagged, discrete interfaces—sub‑optimal when strength, thermal resilience, or integrity is critical.

Enter laser remelting

The research, led by Alexander Schmidt, Felix Jensch and Sebastian Härtel, explores a neat twist: perform L‑PBF as usual but then, after each layer, apply laser remelting to the melt pool. Their experiment used pure copper and low-alloy steel, with layer‑wise remelting to blend materials more thoroughly.

Scanning electron microscopy (SEM) and EDX spectroscopy revealed clearer interfaces—thicker reaction zones, smoother composition transitions, and even novel copper–iron phases forming—thanks to stronger Marangoni convection and thermal diffusion in the remelted layers.

Quality, not just quantity of energy

Increasing the energy density alone might boost mixing—but at a price: increased porosity, keyhole instabilities, and compromised part quality. Laser remelting, by contrast, allows controlled mixing without undermining part integrity.

The reaction zone penetration depth doubles, yet porosity remains minimal—and that’s a vital trade‑off for high‑performance components.

Smooth gradation, stronger parts

By enabling superior FGMs, this technique could have transformative effects:

- Aerospace components can better balance thermal resistance with strength.

- Automotive parts could combine lightweight materials with high‑wear zones—built as one piece, not two.

- Engineers can design complex, graded parts without compromising quality or relying on extra bonding steps.

Simply put, LR‑enhanced L‑PBF may become the key to stepping up gradient manufacturing in demanding sectors.

FGM tech landscape

Additive manufacturing already holds clear advantages in creating FGMs over conventional methods—near‑net shape and robust geometric freedom being prime among them.

Other approaches, like in‑situ powder mixing systems or L‑PBF transitions from one alloy to another, have shown promise in smoothing interfaces. Yet this LR method stands out by combining controlled mixing depth, phase formation, and interface refinement—all without the defects associated with excessive energy input.

Looking ahead

The pioneering implementation of laser remelting during laser powder bed fusion isn’t just a clever tweak—it’s a leap toward reliable, high‑quality graded manufacturing.

By merging materials more gracefully and cutting through mixing challenges, this approach opens doors to better, more resilient designs that industry professionals have long been pursuing.