Driving Precision with Digital Twins to Transform Gearbox Fault Diagnosis

In heavy industry, energy production, and transportation, gearboxes are the workhorses of power transmission. Yet, they often face relentless mechanical stress, high loads, and unforgiving environmental conditions.

When a gearbox fails, the costs can be staggering—not just in repairs, but in production downtime and safety risks. Intelligent fault diagnosis, powered by deep learning, offers a way to predict and prevent failures. But there’s a catch: these AI-driven methods demand vast amounts of labelled fault data, and in practice, acquiring high-quality physical data is expensive, time-consuming, and sometimes downright impractical.

Virtual model-generated datasets could offer a lifeline. However, traditional virtual models often suffer from low fidelity, unreliable data, and poor physical interaction—shortcomings that make them unsuitable for precise diagnosis under real-world operating complexities. This is where the recent research on Digital twin-assisted gearbox dynamic model updating toward fault diagnosis steps in, offering a breakthrough approach.

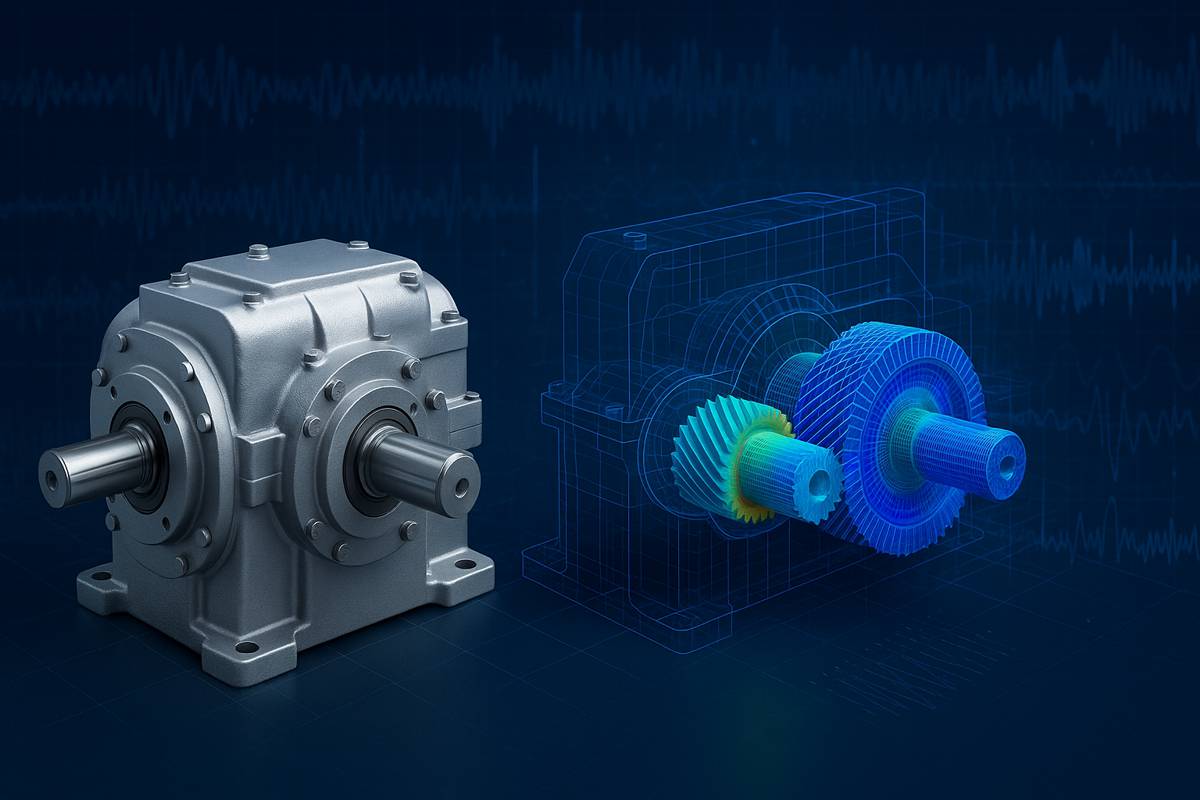

The Digital Twin Approach

The study introduces a method that fuses digital twin technology with dynamic model updating, creating virtual gearboxes whose behaviour mirrors their physical counterparts. The process begins by building a high-precision virtual gearbox model using the rigid-flexible coupling method (RFCM):

- Rigid components such as gear pairs and shafts are modelled as solid bodies.

- Flexible components like the gearbox housing undergo finite element analysis for realistic deformation.

- Rolling bearings are simplified using a bushing force model, striking a balance between computational efficiency and accuracy.

- Gear contacts are simulated with tangential forces based on Coulomb friction and normal forces derived from Hertzian contact theory.

Operating parameters, including input speed and load torque, are matched precisely to the real gearbox, ensuring that virtual conditions faithfully reflect the real-world system.

Validating the Model

A robust model is only as good as its ability to replicate reality. To verify feasibility, the researchers conducted frequency analysis. They compared the main frequencies from the virtual model’s vibration signals to theoretical meshing frequencies and harmonics, applying a strict 5% relative error threshold. If discrepancies exceeded the threshold, adjustments were made to gear contact and bearing parameters until the model achieved alignment.

In testing at 1000 r/min with a load torque of 150 N·m, the virtual signal’s main frequencies, 533.9 Hz, 1067.0 Hz, and 1601.0 Hz, were within 1% of the theoretical values. This confirmed the RFCM-based model’s accuracy and set the stage for further refinement.

Updating the Virtual Model for Greater Fidelity

The researchers then took the model a step further, introducing a physical-virtual signal interaction mechanism. Using cosine similarity, they quantified differences between time-domain signals from the virtual and real gearboxes. Key parameters, contact stiffness (K), damping (C_D), and force exponent (e_F), were identified through sensitivity analysis.

To optimise these parameters without excessive computation, they employed a third-order polynomial response surface model (PRSM) based on 45 Latin hypercube sampling points. The firefly algorithm (FA), inspired by the flashing behaviour of fireflies, was then used to fine-tune parameters and minimise discrepancies.

The results spoke volumes. The FA-optimised parameters boosted cosine similarity between virtual and experimental signals from 0.689 to 0.752, marking a notable improvement in model fidelity.

Real-World Performance Under Varying Conditions

True reliability comes from performance under diverse conditions. When tested across different speeds and load levels, the updated model maintained main frequency errors of less than 1% and cosine similarities above 0.7, with only minor fluctuations. This demonstrated that the approach delivers stable and reliable results, even when operating conditions change.

More importantly, the generated high-fidelity virtual data effectively augmented training datasets for intelligent fault diagnosis systems. This helps overcome the perennial problem of insufficient physical fault data, enabling deep learning models to detect issues earlier and with greater precision.

Implications for Industry

The implications of this research ripple across gearbox-intensive sectors:

- Manufacturing: Preventing gearbox-related production stoppages and reducing maintenance costs.

- Energy: Improving operational uptime in wind turbines, hydro plants, and other energy systems where gearboxes are critical.

- Transportation: Enhancing safety and reliability in rail, marine, and heavy vehicle systems.

By reducing reliance on costly and time-consuming fault data collection, the method speeds up the deployment of AI-driven predictive maintenance. As a result, industries can achieve safer, more stable operations while lowering total lifecycle costs.

Advancing Predictive Maintenance Strategies

The digital twin-assisted approach is not just an incremental improvement, it’s a foundational shift. It provides a scalable framework for building and updating high-fidelity virtual models, which in turn drives better decision-making in maintenance planning.

For policymakers and industry leaders, the study underscores the value of investing in simulation-driven infrastructure. It’s a path toward greater resilience, reduced environmental impact, and improved return on asset investment.

A Positive Outlook

This research offers more than just an academic contribution, it’s a practical toolkit for the next generation of predictive maintenance solutions. By blending engineering precision with AI adaptability, the approach makes it possible to monitor complex mechanical systems with unprecedented accuracy.

As industries navigate the challenges of sustainability, competitiveness, and safety, digital twin-assisted modelling could well become the gold standard for gearbox diagnostics. The ability to foresee faults before they occur not only keeps machinery turning but keeps the wheels of industry moving forward.