Precision Magnetic Measurement for Ultra-Efficient Power Electronics

A pioneering team of Japanese researchers has developed an advanced magnetic Barkhausen noise (MBN) measurement system that promises to revolutionise the understanding and performance of soft magnetic materials, the unsung heroes behind modern power electronics.

Soft magnetic materials, prized for their ability to be magnetised and demagnetised with minimal effort, are core to the operation of transformers, generators, and amplifiers. As the industry pushes toward high-frequency power electronics, demand has surged for low-loss variants that minimise wasted energy. The problem is, a large proportion of these losses come from iron loss, where heat is generated as magnetic fields change, a challenge that intensifies with higher operating frequencies.

Iron loss breaks down into three key types: hysteresis loss, classical eddy current loss, and excess eddy current loss. While the first two are well-understood, excess eddy current loss, caused by erratic domain wall (DW) movements within the material, remains a scientific puzzle, especially in high-frequency scenarios.

Why excess eddy current loss matters

When a varying magnetic field moves through a conductor, it creates swirling electrical currents, much like water eddies in a river. This classical eddy current loss is predictable. Excess eddy current loss, however, emerges from micro-level irregularities: the sudden, localised eddy currents generated when magnetic domain walls jump or shift under changing fields.

Magnetic Barkhausen noise acts as a vital probe for observing these movements. Yet until now, MBN measurement systems lacked the bandwidth and sensitivity to capture individual noise events with the precision needed to understand the relationship between DW dynamics and energy loss.

The Tokyo breakthrough

Led by Assistant Professor Takahiro Yamazaki of the Tokyo University of Science (TUS) Department of Materials Science and Technology, the research team has designed a wide-band, high-sensitivity MBN measurement system capable of detecting previously invisible magnetic behaviour.

Dr. Yamazaki explains: “The most fundamental understanding based on our previous studies is that ‘measure what was previously unmeasurable.’ With our wide-band, high-sensitivity MBN measurement system, we successfully obtained high-fidelity, single-shot capture of individual MBN pulses, providing direct experimental evidence of magnetic DW relaxation in metallic ribbons.”

The study, published in IEEE Access, August 2025, was a collaboration between TUS and the National Institute of Advanced Industrial Science and Technology (AIST), involving Senior Researcher Shingo Tamaru and Professor Masato Kotsugu.

Inside the new measurement system

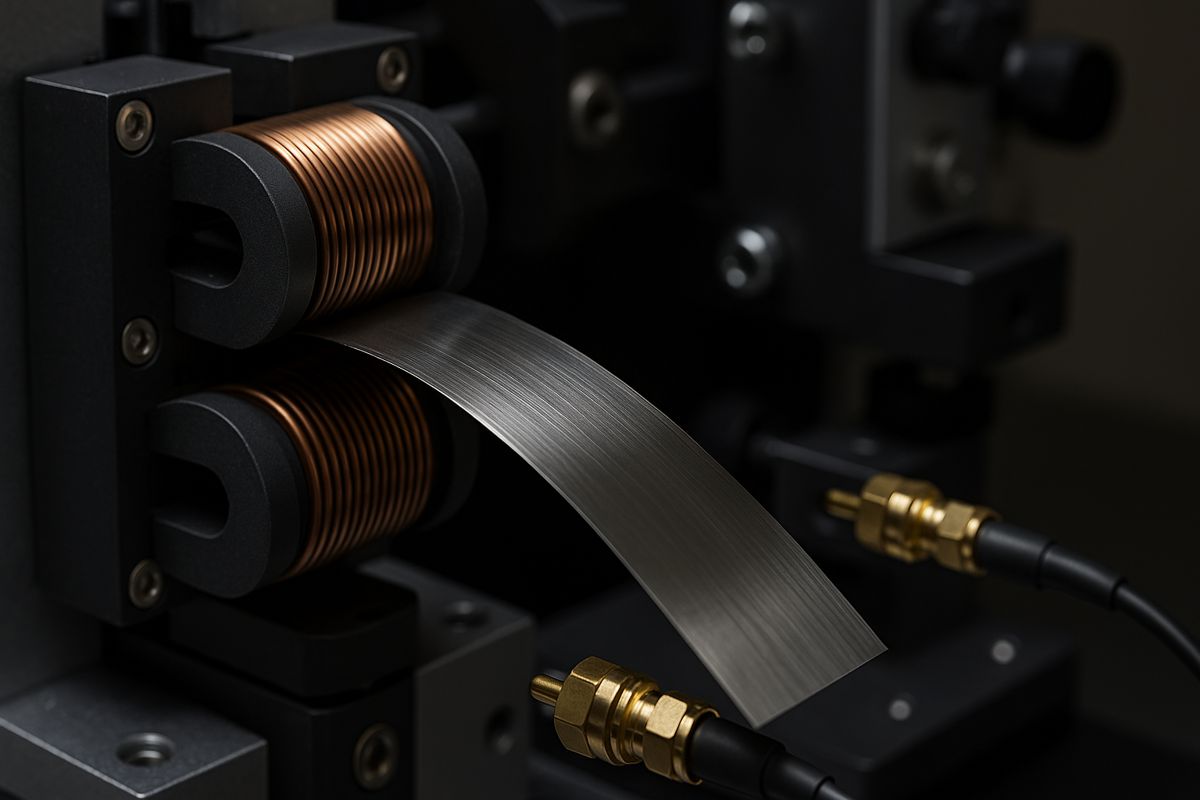

The team’s innovation combines a dual-layer coil jig with comprehensive electromagnetic shielding and a custom low-noise amplifier. This meticulous design minimises background interference while ensuring a wide operational bandwidth. The result is crystal-clear detection of individual Barkhausen events.

Using 25 μm-thick Fe–Si–B–P–Cu (NANOMET®) ribbons, a leading class of soft magnetic alloys, the system delivered unprecedented clarity. The captured MBN pulses revealed direct signs of DW relaxation, with statistical analysis indicating a mean relaxation time constant of about 3.8 μs and a standard deviation of 1.8 μs, significantly below predictions from existing theoretical models.

Rethinking the physics of magnetic losses

These results prompted the researchers to propose a new physical model of domain wall relaxation. Their findings point to damping from eddy currents generated during DW motion as the main driver of excess eddy current loss – not the intrinsic magnetic viscosity of the domain walls themselves.

This insight bridges a critical knowledge gap and offers a roadmap for designing materials that inherently minimise excess losses, especially for high-frequency applications.

Heat treatment and microstructural control

The team extended their study to heat-treated nanocrystalline NANOMET® ribbons. The results were striking: the amplitude of MBN pulses dropped sharply, signalling a more uniform and controlled DW motion. This confirmed that targeted microstructural adjustments can smoothen DW behaviour, directly cutting energy loss.

Such improvements could have immediate implications for industries striving for higher efficiency in renewable energy systems, electric vehicle (EV) drivetrains, and advanced power electronics.

Industry potential and future applications

By partnering with manufacturers, the research could accelerate the integration of optimised NANOMET® materials into next-generation components for:

- High-frequency transformers

- Compact, lightweight EV motors

- Renewable energy converters

Dr. Yamazaki is optimistic about the system’s broader impact: “Our method has the potential for wide application in the design of next-generation low-loss soft magnetic materials, especially in high-frequency transformers, electric vehicle motors, paving the way for smaller, lighter, and more efficient devices.”

Driving efficiency forward

The combination of direct experimental evidence, advanced modelling, and practical microstructural control means the days of treating excess eddy current loss as a mystery could be over.

This work doesn’t just deepen the scientific understanding of soft magnetic materials, it opens a pathway to more sustainable, energy-efficient technologies that will underpin the next wave of electrification.