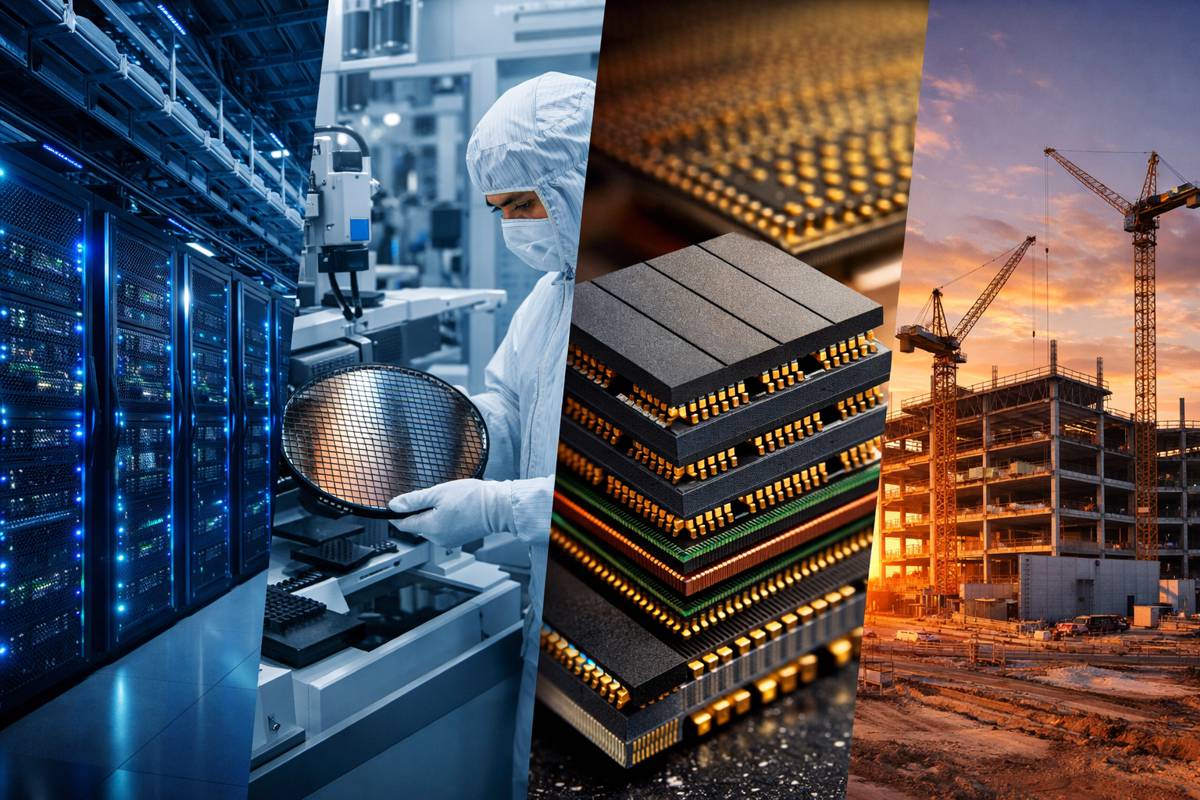

How Real‑Time Data Fuels Manufacturing Productivity Gains

Even as UK factories hum with machines, stock flows, and sensors, only a fraction of their digital chatter translates into immediacy and insight. Nearly half of manufacturers admit that data integration and system complexity are throttling automation and growth, while three‑quarters say real‑time data is critical, yet few manage to harness it in time to make a difference.

“It isn’t the volume of data that chokes,” notes Alex Douglas, Client Development Director at Pulsant, but the absence of clarity over which datasets truly matter, where they must be processed, and how swiftly. Without that precision, systems balloon in cost—and often action comes far too late.

The Key Roadblock

Construction and industrial production never wait around. Whether it’s a looming motor overheat, stock discrepancy, or misaligned packaging, only nimble systems, those that surface anomalies in real time, save both time and money. The issue is grim: slow, centralised systems drown operations in noise before any data becomes usable.

That’s precisely the promise of edge computing. By performing critical analysis alongside machines, not halfway across cyberspace, factories shave off latency and avoid dependency on distant cloud infrastructures. The result? Smoother workflows, smarter staff interventions—and savings on bandwidth and processing premiums.

Edge Computing in Action

Here’s how edge computing is shaping modern manufacturing:

- Predictive maintenance: On‑site analytics spot wear and tear before failure strikes, cutting unplanned downtime and boosting equipment lifespan.

- Real‑time control & adaptation: AI and ML models run locally to adapt on the fly—from packaging speeds to quality inspection.

- Resilience & reliability: Even when the internet hiccups or cloud systems falter, edge‑empowered sites stay online.

- Security and governance: Keeps sensitive, operational data within defined boundaries—easing compliance with ISO 27001 and data sovereignty rules.

platformEDGE, Pulsant’s UK‑wide edge‑computing backbone, combines regional data centres, a low‑latency private network, and secure processing nodes. Its rollout across 12 data centres, including Rotherham and Manchester, underscores the national push for localised, fast, and compliant data handling.

How Smart Data Strategies Drive Efficiency

When manufacturers target, not hoard, data, the benefits become almost immediate:

- Predictive vs reactive operations – Engineers shift from fire‑fighting to problem‑averting.

- Streamlined supply chains – Inventory and lead times tighten; just‑in‑time becomes just‑right.

- Unified dashboards – Executives access synchronized, real‑time data—not delayed snapshots.

- Cost containment – By filtering data locally, bandwidth and storage costs plummet.

- Regulatory ease – Governance improves, especially when sensitive or regulated data stays on‑site.

- Resilience – Local processing buffers against cloud outages and network latency.

A Hybrid Path

Pure edge or cloud-only? Not any more. The smarter approach is a hybrid edge‑to‑cloud model: process mission‑critical data locally, while sending aggregated insights to the cloud for broader AI training, historical analysis, and business intelligence. This model:

- Delivers low latency where it’s vital, and scalability where it counts.

- Supports real‑time monitoring on‑site and long‑term learning in the cloud.

- Drives predictive maintenance that can cut maintenance costs by 10–40% and downtime by half—or more—and extend equipment life by 20–40%.

Tech analysts agree that most manufacturers aren’t yet AI‑ready, not for lack of data, but inability to clean, structure, and coordinate it. A tidy, governed foundation, often in the form of a data lakehouse, is an essential step toward real‑time AI applications.

Building the Foundation

To turn real‑time data into productivity gains, manufacturers should:

- Audit data readiness – Clean, enrich, and tag data so AI models and dashboards can use it reliably.

- Bridge IT and OT – Break down silos: standardise metadata, timestamps, and units across systems.

- Invest in flexible architecture – Ditch old batch processing for fast, modern systems built for streaming and agility.

- Deploy pilots – Start small—but smart: focus on one plant or process to make the case with measurable gains.

- Select edge platforms wisely – Opt for regional, secure platforms like platformEDGE for compliance, speed, and scalability.

- Design governance & security – Secure endpoints, enforce access controls, and preserve traceability.

- Loop real outputs back – Feed cloud‑trained models back to the edge to sharpen local intelligence.

The Industrial Edge

In the UK’s shifting manufacturing landscape, where margins are tight and delays expensive, the power of real‑time analytics is hard to overstate. Whether it’s predictive maintenance, streamlined logistics, or operational resilience, edge computing enables manufacturers to react in seconds—not hours.

As one industry insider might say, relevance beats volume. With powerful platforms like platformEDGE and a hybrid edge‑cloud blueprint, manufacturers have the tools to stand sharper, more responsive, and ever more productive.

Next Steps

Manufacturers, construction professionals, policy makers, and investors alike stand to benefit from:

- Supporting digital infrastructure investment – Especially regional edge capabilities.

- Encouraging data literacy – Train staff to interpret and act on real‑time insights.

- Funding pilot schemes – Showcase ROI early—and scale fast.

With data flowing at speed, it’s high time the industry caught up—and turned raw streams into real‑world outcomes.