Liebherr Machinery and Sustainability Sets the Stage for NordBau 2025

From 10 to 14 September 2025, Liebherr will be in the spotlight at the NordBau trade fair in Neumünster, showcasing an impressive line-up of construction machinery designed to tackle everything from deep foundation projects to urban earthmoving.

The event, held at the Holstenhallen Congress Centre, is one of Northern Europe’s leading construction showcases, drawing industry professionals from across the region. Liebherr’s stand N 224 in the northern outdoor area promises visitors a hands-on look at cutting-edge machines alongside insights into its expanding remanufacturing programme.

LRB 19 Piling and Drilling Rig with LV 23 High-Frequency Vibrator

The centrepiece of Liebherr’s deep foundation display is the LRB 19 piling and drilling rig, paired with the LV 23 high-frequency vibrator. This rig is engineered for the most demanding ground engineering tasks, delivering 450 kW of muscle via its BAT 180.1 drilling drive, capable of producing a hefty 180 kNm of torque. Whether using Kelly equipment, double drill heads, or soil mixing tools, the LRB 19 excels in performance and precision.

The LV 23 vibrator enhances the package by driving steel sheet piles, steel pipes, and other pile-driving elements deep into the ground or extracting them with equal ease. Thanks to Liebherr’s hydraulic quick coupler, attachments can be swapped without tools, directly from the cab, with all connections automatically engaged. The self-assembly system for ballast means no extra crane is required, saving time and resources during setup.

Safety and accuracy are bolstered by Liebherr’s suite of assistance systems. The work area restriction tool prevents accidental movement into restricted zones, while the LIPOS positioning system uses satellite data for pinpoint alignment. Automated concreting via the drilling assistant and precision in vibratory compaction through the vibration assistant further streamline operations.

A 911 Compact Wheeled Excavator

In bustling city centres and tight construction zones, the A 911 Compact wheeled excavator is built to shine. With a tail swing radius of just 1.60 metres and a front swing radius of 2.10 metres, it navigates confined spaces effortlessly. Power options include 55 kW or 80 kW engines, with SCR systems and after-coolers for emissions compliance.

The sensitive hydraulics, intuitive controls, and formidable digging forces make it a versatile workhorse, especially when paired with diverse attachments. Liebherr’s robust undercarriage design delivers rapid acceleration and high traction, with the Speeder variant achieving up to 37 km/h. Multiple tyre configurations, including dual tyres, ensure optimal stability, while the spacious cab offers operator comfort and the flexibility of the INTUSI operating interface.

L 506 Compact Loader

The L 506 Compact loader brings a winning combination of manoeuvrability, stability, and payload capacity. Suited for road construction, municipal services, and rental fleets, its low centre of gravity minimises tipping risk while boosting load performance. The hydrostatic travel drive ensures smooth, uninterrupted acceleration, with the Speeder version topping out at 30 km/h.

Liebherr’s Solidlink quick coupler system allows rapid attachment swaps from within the cab, enabling operators to adapt to varied tasks in seconds. The ergonomic cab design, extensive glazing for improved visibility, and ground-level maintenance access make the L 506 a practical choice for both performance and safety.

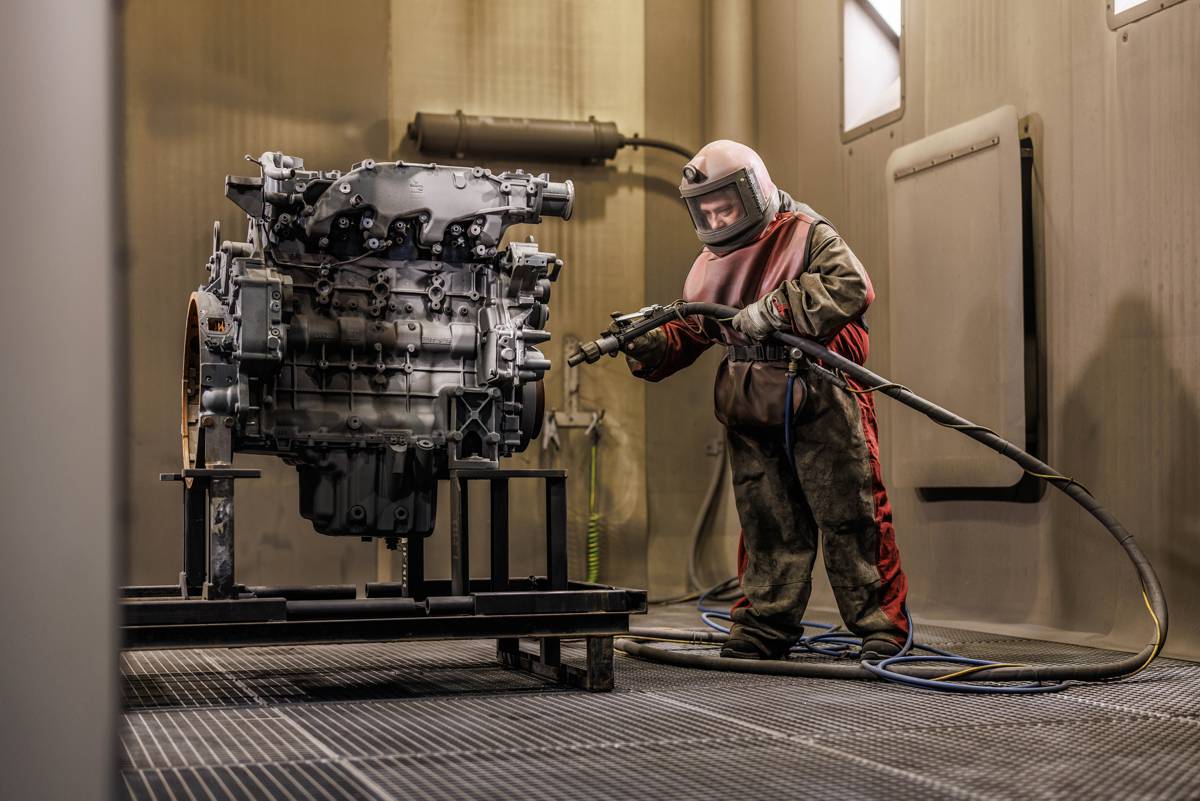

The Remanufacturing Programme

In the pavilion at stand N 224, Liebherr will spotlight its Reman programme, a testament to its commitment to resource efficiency. Remanufacturing involves dismantling, cleaning, and refurbishing used components, from engines and hydraulic pumps to gearboxes and winches, bringing them back to as-new performance standards.

With three service levels, component replacement, general overhaul, and repair, the programme reconditions 7,500 components annually across 15 global sites. Customers benefit from up to 50% cost savings compared to new parts, while environmental gains include conserving up to 78% of raw materials in engine reconditioning. This approach supports both operational cost efficiency and sustainable practices.

A Global Leader

Founded in 1949 by Hans Liebherr in Kirchdorf an der Iller, the family-run Liebherr Group has grown into one of the world’s largest construction equipment manufacturers, employing over 50,000 staff across more than 150 companies worldwide. In 2024, the Group recorded revenues exceeding €14 billion, driven by its ethos of continuous innovation and customer-focused solutions.

NordBau 2025 will once again provide a platform for Liebherr to demonstrate not only its engineering excellence but also its dedication to sustainability and industry leadership. For construction professionals, it’s an unmissable opportunity to see the future of machinery in action.