Advanced Metal Fabrication and the Future of Highway Infrastructure

Highway networks stand on steel and precision. Behind every bridge beam, guardrail, or tunnel frame lies the unseen work of metal fabrication. The strength, safety, and longevity of roads depend not just on concrete and asphalt but on the fabricated metal components that hold everything together.

This article explores how technologies like press brakes and laser cutters are reshaping the way highways are designed, built, and maintained.

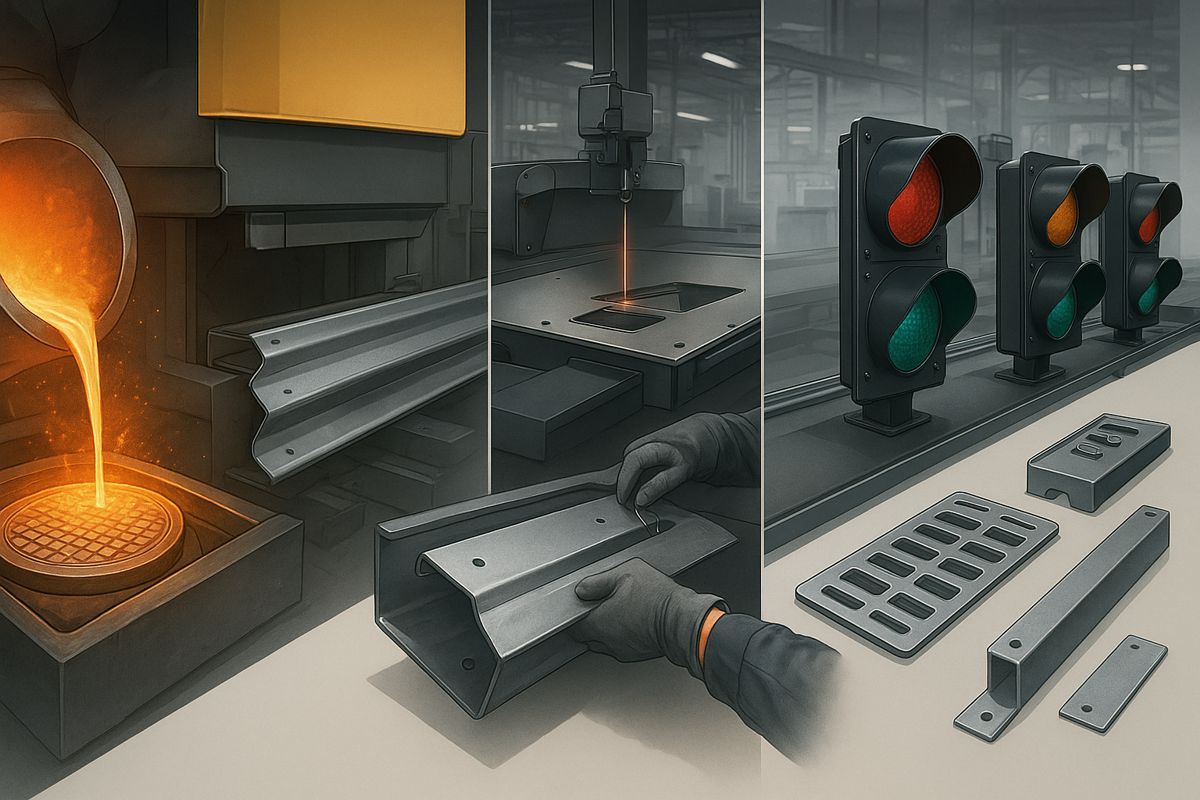

Metal fabrication, in the context of infrastructure, is the industrial process of cutting, bending, and assembling metal into usable structures for transportation projects. From guardrails to massive bridge supports, these parts must meet exacting standards. Precision fabrication ensures that roads remain durable, safe, and adaptable to the demands of modern transportation.

Why Does Metal Fabrication Matter for Highway Infrastructure?

Fabricated metals are the backbone of transportation systems. Bridges, tunnels, and overpasses rely on structural components with precise tolerances to withstand immense weight and environmental pressures. Guardrails and barriers protect lives by absorbing and redirecting impact forces. Signage, culverts, and drainage systems all depend on metals shaped and fitted with accuracy.

Without fabrication, highway infrastructure would lack uniformity and reliability. Poorly shaped beams or misaligned brackets can reduce load-bearing strength and create long-term safety risks. Advanced fabrication methods mitigate these problems, delivering parts that perform consistently even under extreme stress.

Typical fabricated components in highways include:

- Bridge beams and reinforcements

- Guardrails and crash barriers

- Road and traffic signage

- Culverts and drainage pipes

- Structural support brackets and joints

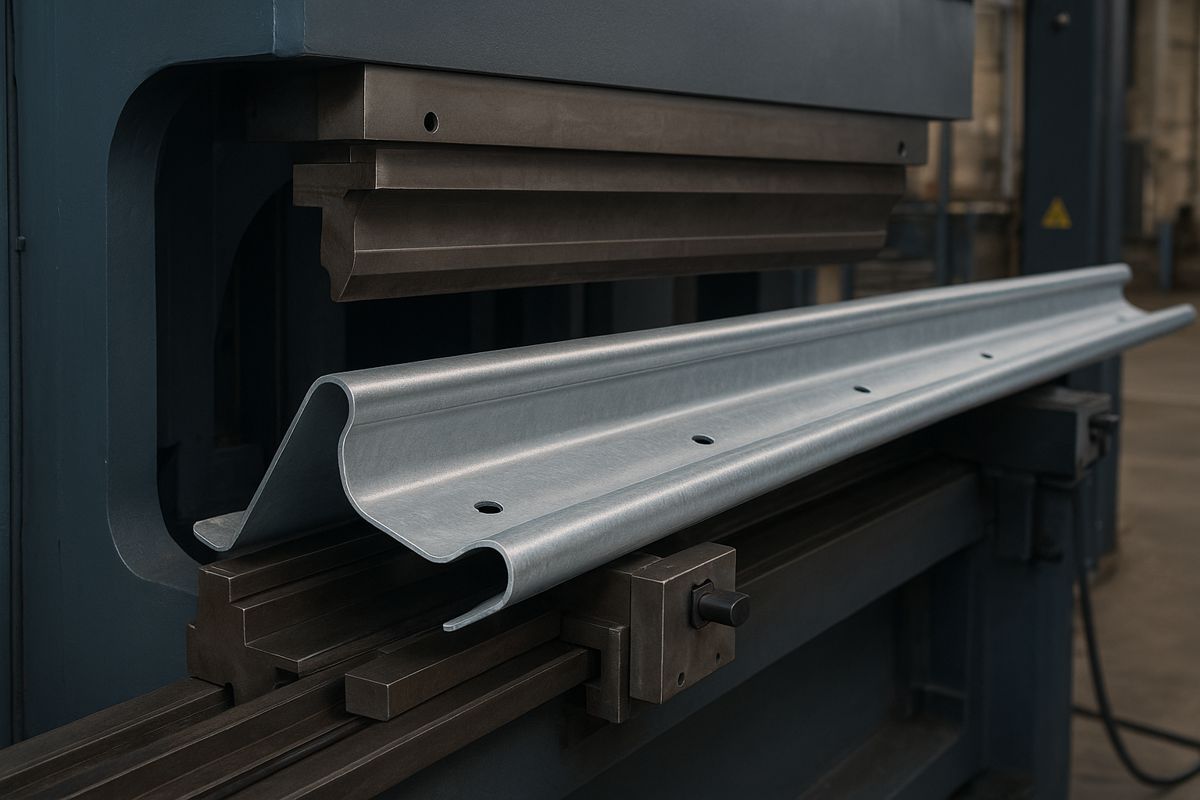

How Do Press Brakes Shape the Future of Road and Bridge Projects?

Press brake machines are machines that bend sheet metal into specific shapes by applying force along a straight axis. In highway projects, their accuracy ensures that beams, panels, and barriers are produced to exact specifications. Even small deviations in bending angles can compromise stability, so consistency is non-negotiable.

Key highway applications for press brakes include:

- Bridge reinforcements and stiffeners

- Crash barriers and guardrails

- Road signage frames and posts

- Drainage and culvert systems

What Are the Advantages of Using CNC Press Brakes in Infrastructure?

Computer-controlled press brakes (CNC) add precision and efficiency to fabrication. Their benefits include:

- Consistent precision across multiple parts

- Repeatability for large-scale projects

- Reduced material waste through accurate bends

- Strength uniformity across structural components

- Faster project timelines due to automation

How Does Automation Improve Press Brake Efficiency for Road Projects?

Modern press brakes integrate robotics, sensors, and advanced software to optimize workflows. Automated handling systems reduce manual errors and speed up production cycles. Sensors measure real-time bending angles, ensuring that even thick sheets meet tolerance requirements. Software integration allows engineers to simulate and adjust designs before a single sheet is bent, minimizing costly rework.

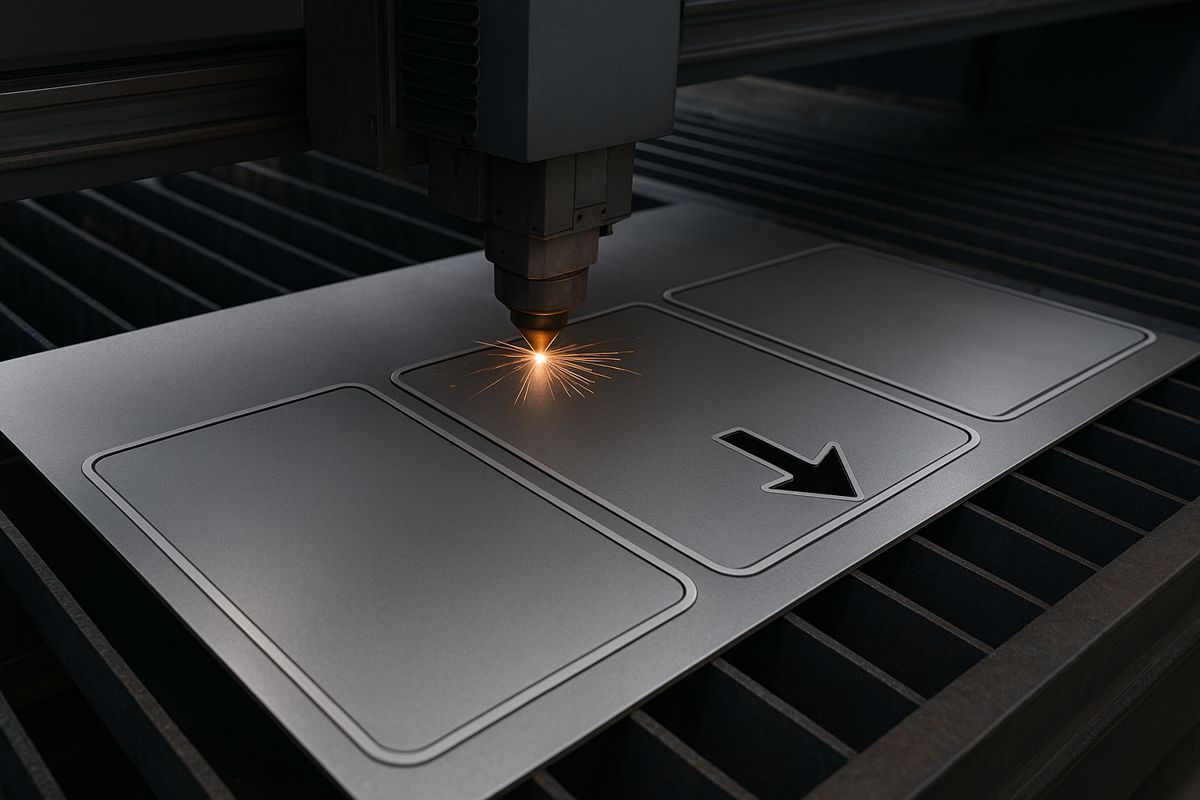

Can Laser Cutting Provide Better Components?

Laser cutting complements press brakes by shaping sheets and plates into precise, custom-fit components.

Unlike traditional methods such as plasma or mechanical cutting, lasers provide smooth edges, minimal distortion, and rapid turnaround. In highway projects, where every part must integrate seamlessly, this level of detail is crucial.

How Does Laser Cutting Work in Infrastructure Applications?

The process follows structured stages:

- Importing and processing design files

- Focusing the laser beam on the workpiece

- Executing the cut with high-intensity light

- Conducting post-cut quality checks for precision

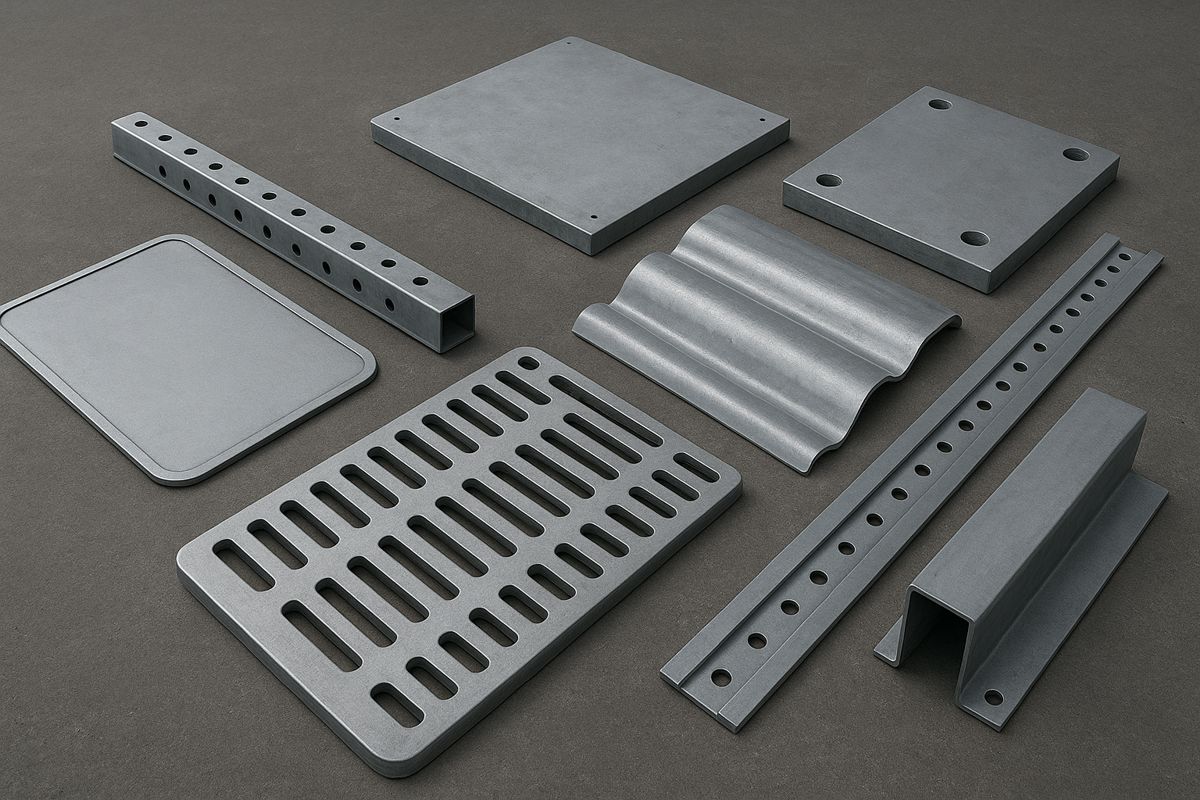

Which Highway Components Benefit Most from Laser Cutting?

Laser cutting plays a role in fabricating:

- Guardrails and safety barriers

- Lighting poles and mounting fixtures

- Structural joints and connectors

- Noise barriers and shielding panels

- Custom safety features for tunnels and bridges

What Are the Advantages of Laser Cutting Over Traditional Cutting for Infrastructure?

Laser cutting improves outcomes with:

- Higher precision and tighter tolerances

- Minimal distortion of edges and surfaces

- Faster cutting speeds for large projects

- Ability to process oversized sheets of metal

- Flexibility to handle complex geometries

What Types of Metals Are Commonly Used in Highway Construction?

Different projects require different metals based on durability, corrosion resistance, and cost efficiency. Fabricators select materials that balance strength and workability.

Steel (Mild and Stainless)

- High tensile strength for bridges and heavy loads

- Corrosion resistance in stainless grades

- Cost-effective and widely available

Aluminum

- Lightweight and corrosion resistant

- Ideal for signage and lighting structures

- Easy to transport and fabricate

Galvanized Steel

- Coated for enhanced rust protection

- Used in guardrails and barriers

- Long service life in harsh conditions

Copper and Brass (for wiring and fittings)

- High electrical conductivity for lighting systems

- Durable and resistant to wear in connections

- Easy to fabricate into fittings

Titanium and Specialty Alloys (for bridges and high-performance structures)

- Exceptional strength-to-weight ratio

- Resistance to corrosion in marine or coastal environments

- Long-term durability despite higher costs

How Do Fabricated Metal Parts Improve Safety and Longevity of Roads?

Durability and safety depend on precision-made parts. Fabricated metals withstand repeated loads, resist corrosion, and absorb impact without failure. They help roads last longer and require less frequent repairs, reducing long-term maintenance costs.

Benefits include:

- Resistance to corrosion from moisture and chemicals

- Improved fatigue strength under constant use

- Structural reliability against earthquakes and wind

- Extended service life for bridges and road components

What Role Does Sustainable Fabrication Play in Road-Building?

Sustainability is no longer optional in infrastructure. Eco-friendly fabrication focuses on recycling metals, reducing energy use, and optimizing processes. These practices align with government regulations and public demand for greener projects.

Key advantages include:

- Lower energy consumption in production

- Reduced waste through precise cutting and bending

- Smaller carbon footprint across supply chains

- Longer lifecycle of fabricated components

Can Precision Fabrication Reduce Material Waste in Highway Projects?

Yes. Advanced software layouts allow engineers to maximize sheet utilization, minimizing offcuts. Laser cutters produce parts with tight tolerances, reducing the need for rework or scrap. The result is less waste, lower costs, and more efficient use of raw materials.

What Are the Challenges of Using Advanced Fabrication in Infrastructure?

While the benefits are significant, challenges remain. High-tech fabrication equipment requires large capital investments, skilled operators, and regular maintenance. Supply chain disruptions can delay projects if parts or machines are unavailable.

Key challenges include:

- High initial equipment costs

- Operator training and technical expertise

- Maintenance and calibration demands

- Project delays from supply chain bottlenecks

Which Innovations Are Shaping the Future of Fabrication for Highways?

The next generation of infrastructure relies on automation, robotics, and digital integration. Industry 4.0 tools connect machines and engineers in real time, improving quality control.

How Is Automation Changing Large-Scale Road Projects?

Automated fabrication lines reduce downtime, accelerate delivery, and provide predictive maintenance alerts. Contractors can monitor equipment remotely, ensuring projects stay on schedule.

Can 3D Metal Printing Complement Press Brakes and Laser Cutters?

Emerging 3D printing solutions already support modular bridges and custom joints. Hybrid projects combine traditional fabrication with additive techniques, creating flexible, lightweight structures that were impossible a decade ago.

How Do Contractors Choose the Right Fabrication Equipment for Highway Projects?

The choice of equipment depends on multiple factors:

- Scale and scope of the project

- Types of metals being processed

- Required tolerances and precision levels

- Available budget and operating costs

- Maintenance demands and supplier reliability

What Are the Best Practices for Working With Fabrication Partners?

Contractors should evaluate partners on:

- Certification and compliance with standards

- Proven case studies in infrastructure

- Technical support availability

- After-sales service and maintenance agreements

Defining How Roads and Bridges are Built

Metal fabrication is more than an industrial process; it is the hidden framework that keeps highways strong, safe, and sustainable. Press brakes deliver bending accuracy for structural parts, while laser cutters shape components that must fit seamlessly under heavy use. Together, they extend the life of infrastructure, reduce costs, and enable smarter road designs.

Looking forward, the integration of automation, digital tools, and sustainable practices will define how roads and bridges are built. Precision fabrication ensures that the highways of tomorrow will not only carry more traffic but also stand as resilient, eco-conscious systems built to last.