AI and Smart Tech for Safer Construction Sites

Emerging technologies are rapidly transforming construction sites from traditional hazard zones into smarter, safer workplaces. Artificial intelligence (AI) and digital tools are enhancing how crews stay out of harm’s way and how they learn vital skills.

The once paper-driven, intuition-led approaches to safety and training are giving way to data-driven, proactive strategies. From computer vision systems that spot dangers in real time to virtual reality simulations that let workers practice risky tasks without real-world consequences, innovation is placing safety at the forefront. Equally important is the human element, to create a cultural shift on site as workers and managers embrace these gadgets and systems.

In an industry where about 20% of all workplace fatalities occur, these AI-driven advancements aren’t just high-tech gimmicks; they’re potential life-savers and game-changers for productivity. Construction professionals, investors, and policymakers alike are taking note that technology and safety now go hand in hand on the jobsite, ushering in a new era where progress and well-being go together.

Hazard Detection and PPE Compliance

On a busy construction site, hazards can emerge in the blink of an eye, a worker stepping too close to a swinging excavator, an unmarked live wire, or someone forgetting to don their hard hat. AI-powered vision systems are becoming the jobsite’s 24/7 sentinels, continually scanning for such dangers and ensuring compliance with safety rules. High-resolution cameras paired with machine learning algorithms can now recognise when workers are missing essential personal protective equipment (PPE) like helmets or high-vis vests. Instead of a supervisor catching violations hours later, an AI system can instantly flag a breach. In fact, early implementations have shown promising results: one automated hard-hat and vest detection system reportedly cut workplace accidents by up to 50% by alerting supervisors the moment safety gear isn’t worn. The approach is proactive, stopping an incident before it happens rather than reacting afterward.

These “AI safety eyes” don’t get tired or distracted. They can identify risks that humans might overlook, such as an unguarded edge, missing barrier or unstable scaffold, and notify site managers in real time. Some systems go further by analysing patterns in the footage. Over time, they learn to recognise near-misses, for example, frequent trips in a cluttered area or recurring speed violations by vehicles, allowing companies to address root causes. “AI-powered vision systems operate continuously, detecting PPE non-compliance instantly with consistent accuracy throughout all operational hours,” notes one industry report. By observing everything on site, AI becomes an ever-vigilant safety officer that never blinks.

Heavy equipment manufacturers are also integrating AI-based hazard detection into machines to protect both operators and ground crews. Modern construction vehicles can be outfitted with 360° cameras and edge AI processors that act as an extra set of eyes for the driver. For instance, Leica Geosystems’ new Xsight360 system uses intelligent vision to detect people or other objects in a machine’s path and immediately trigger audible and visual alerts.

Crucially, the system pinpoints the hazard’s location and distance, so the operator can take evasive action before an accident occurs. All this happens in split seconds, a huge advantage when the top two causes of construction vehicle collisions are human speed and distraction. Not only do these AI assistants minimise blind spots, they also log near-miss data to the cloud. Safety managers can review dashboards of these incidents, compare them against safety policies, and refine training or site layouts accordingly. This turns every alert into actionable insight. As Neil Williams, President of Leica Geosystems’ machine control division, explains: “With our partner, we’ve developed an intelligent, adaptive system that enhances safety in the present with instant alerts and shapes future safety strategies through comprehensive reports”. In essence, AI isn’t just reacting to hazards, it’s helping construction firms get ahead of them.

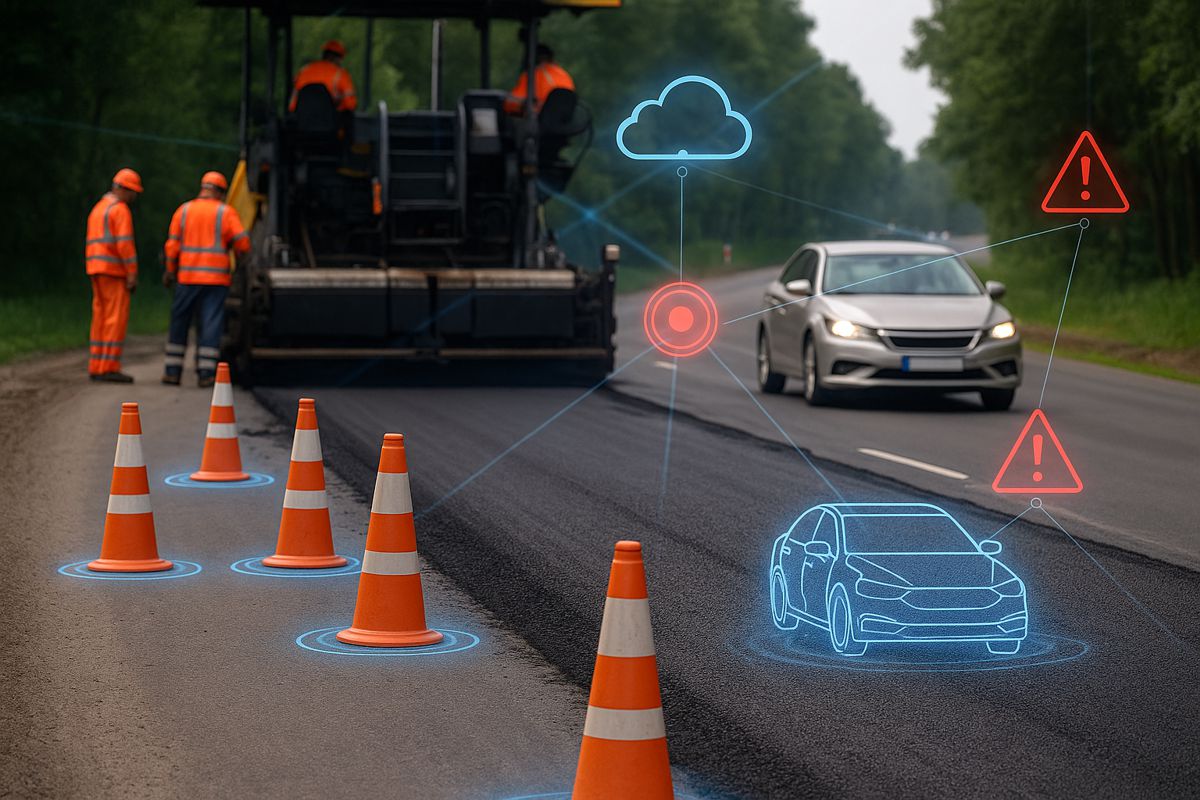

AI-driven hazard detection extends even to traffic and road work zones, where dangers come from both heavy machinery and passing vehicles. Collision avoidance systems that combine cameras, sensors and AI are now being used to automatically slow or stop machinery when an obstacle (like a person or another vehicle) is too close. On highway projects, smart CCTV setups can monitor live traffic approaching work zones and warn crews if an errant driver doesn’t slow down. It’s a vital development at a time when nearly 900 people were killed in work zone crashes in 2023.

By employing intelligent surveillance and automated alerts, contractors aim to reverse this trend and make sure that everyone, workers and motorists alike, gets home safe. All told, AI vision systems are quickly becoming the guardian angels of the jobsite, identifying risks, enforcing PPE rules, and preventing accidents before they happen.

AR and VR Transforming Training

Traditional safety training, think binders of protocols, slide presentations, or one-off demonstrations, often struggles to hold attention or convey the urgency of real hazards. That’s changing as construction firms turn to augmented reality (AR) and virtual reality (VR) to train their workforce in more engaging, hands-on ways. AR and VR bring a dose of immersion that can make a life-saving difference when workers face actual peril on site.

According to industry estimates, AR/VR applications have positively impacted over 23 million jobs globally, improving safety and productivity across sectors. And the momentum is only growing: the AR/VR market is projected to soar to $250 billion by 2028 as more companies invest in these tools. In construction, AR and VR are proving to be far more than just high-tech toys, they’re becoming key instruments in building a safer, more skilled workforce.

With VR, crews can step into a simulated construction environment and practice dangerous tasks without real-world consequences. For example, trainees can virtually operate a tower crane in a busy city centre, handle a sudden load swing or even experience an equipment failure, all inside a headset and computer simulation. If a virtual steel beam is dropped from 30 stories or a trench wall collapses in the simulation, no one is hurt. Virtual classroom accidents result in app resets rather than real injuries, as one training expert quipped. This risk-free repetition builds muscle memory and confidence. Workers can make mistakes and learn from them, so that on a live site they’ve essentially “been there, done that” and know how to react correctly under pressure.

The benefits of immersive training are backed by learning science. Studies show that interactive simulations ensure better knowledge retention and skill development compared to lecture-style learning. It’s the difference between reading about a fire on site versus actually navigating one in VR. In a virtual reality module, a worker can practice a trench rescue or scaffold erection technique repeatedly until they master it, all while instilling safe habits. Crucially, this can be done at a fraction of the cost and risk of traditional training which might require taking equipment out of service or setting up controlled hazard scenarios.

“VR has taken safety training to a whole new level. Instead of learning about safety through videos or manuals, workers can now immerse themselves in realistic simulations of construction environments,” notes a Volvo Construction Equipment safety report. The result is not only more engaged trainees but also workers who feel more prepared and less likely to panic or err in real emergencies.

Augmented reality is also making inroads on the training front, often literally on the jobsite itself. Unlike VR’s fully virtual world, AR overlays digital information onto the real world through devices like smart glasses or mobile tablets. This means a site supervisor wearing AR glasses could walk through an unfinished building and see virtual markers highlighting, say, the planned routing of electrical cables behind walls or the safe zones to stand while a robot is welding nearby.

In training contexts, AR can guide new workers by displaying step-by-step instructions or safety checkpoints in their field of view as they perform a task. One highway contractor described using an AR app during safety orientations: trainees would hold up a tablet in an equipment yard and see virtual danger zones radiating around an excavator, teaching them where not to stand during operation. AR effectively adds a digital safety coach to real workplaces: it can warn if a worker is about to make a wrong move in real time. For instance, an AR helmet might sound an alert if it “sees” the wearer reaching for the wrong valve or entering a restricted area, based on image recognition.

Beyond teaching specific procedures, AR/VR are improving overall safety culture through engagement. Younger construction workers, raised on video games and smartphones, often respond enthusiastically to immersive training, it feels more like an interactive challenge than a dull requirement. Even seasoned tradespeople find that realistic simulations can refresh their awareness. They might “virtually” experience an electrocution or a fall in VR and gain a healthy respect that traditional training might not instil as effectively.

When these tools are used in groups, they spark conversations among crew members about best practices and “what-if” scenarios, reinforcing collective learning. The bottom line is that AR and VR are turning safety training from a checkbox exercise into an active, impactful experience. By practicing in a virtual world, construction crews are far better prepared for the real one, making worksites safer for everyone involved.

Sensors Fight Fatigue and Keep Workers Healthy

Construction is a physically demanding and often perilous profession, one where a momentary lapse, like a fainting spell or a slip, can be catastrophic. Enter the new generation of smart wearables: gear equipped with sensors and connectivity that actively monitors workers’ well-being and environment. This isn’t your grandfather’s hard hat and steel-toed boots. Today’s safety helmets can detect if you’ve taken a fall or even if you’re nodding off from fatigue.

Vests can track your heart rate and core temperature, warning of heat stress before you collapse. Boots can sense when you’ve stepped too close to a moving vehicle and sound an alarm. Essentially, wearables create an invisible safety net around each worker, one that’s always watching for danger even when human eyes are not.

Consider the smart hard hats now on the market. Many come outfitted with accelerometers and gyroscopes. If a worker slips or is struck on the head, the hat automatically detects the impact and triggers an emergency alert, sending the person’s exact location to response teams. In the frantic moments after an accident, this instant distress call can shave off critical minutes for medical intervention.

There are also hard hat models with built-in brainwave sensors that detect microsleeps, those tiny lapses in alertness when a worker is exhausted. The hat can vibrate or signal to wake the person up before a micro-nap becomes a fall from scaffolding. Meanwhile, wearable wristbands and arm straps are tackling the silent threat of fatigue. They continuously monitor vital signs like heart rate, blood oxygen, and skin temperature. If readings indicate extreme fatigue or heat exhaustion (e.g. elevated heart rate combined with rising body temp and slowed activity), the system will alert both the worker and the supervisor that it’s time for a break.

One popular product, the SmartCap Life band, even analyses brain activity for fatigue levels and has been successful in ensuring workers take breaks when necessary to avoid dangerous mistakes. Given that fatigue contributes to an estimated 13% of workplace injuries, and nearly half of construction firms report safety incidents due to tired employees, so these alerts can literally be lifesavers.

Other wearables focus on environmental hazards. Smart vests are available with built-in air quality sensors and noise level monitors, effectively turning the worker into a walking environmental station. If a crew member enters a pocket of toxic gas or the din of machinery exceeds safe decibel levels, the vest will warn them immediately to ventilate the area or put on hearing protection.

Some high-tech vests and jackets also feature GPS-based geofencing: if the wearer wanders into a restricted zone (say, too close to a crane lift or an off-limits excavation), both the worker and the machine operator can get instant alerts to prevent a dangerous encounter. Likewise, sensor-embedded boots vibrate or beep if they detect certain conditions, for example, a boot might register an impact (indicating the person tripped or fell) or sense a vehicle’s proximity via RFID and signal the worker to be alert.

The impact of these wearables on safety is already evident. A few years ago, only about 13% of contractors were using wearable tech on sites, yet 82% of those early adopters reported improvements in safety and productivity. The data collected by wearables not only prevents incidents in the moment, but also helps companies spot patterns and make long-term changes. For instance, if aggregated data from wristbands and hardhats shows that most near-misses happen during late afternoon hours when heat stress peaks, management can schedule extra water breaks or rotate tasks at noon to mitigate risk.

“Wearable sensors can improve construction worker safety and also reduce costs by providing better data on worker health,” says SangHyun Lee, a civil engineering professor who researches such technology. Insurers are taking notice too, and some now offer premium discounts to firms using verified smart PPE, since real-time health monitoring and fewer accidents mean fewer claims. It’s an appealing proposition: invest in wearable tech, save lives and money at the same time.

Real-world examples of wearables in action illustrate just how diverse and creative this field has become. On some sites, workers don smart shirts that monitor posture; if a worker repeatedly bends or lifts incorrectly, the shirt sends a coaching alert to adjust their form, preventing long-term musculoskeletal injuries. A start-up called WakeCap has developed a network of helmet sensors that track crew locations and can detect if someone hasn’t moved for a while, potentially indicating an accident. If an evacuation is needed (like a fire or collapse scenario), the system automatically checks who is still inside and guides them out with directed alerts, a far cry from the old “air horn and headcount” method.

All of this contributes to a new, data-enriched safety culture. Instead of blaming individuals for incidents, managers and workers can look at the hard data from wearables to discuss solutions. “We’re not trying to watch or control people. We’re gathering info that shows we, as employers, are giving workers a safe place to do their jobs,” explains Brett Burkhart, a safety technology specialist at MākuSafe, emphasising that transparency with sensor data builds trust on both sides. In short, wearables are turning each worker into a source of insight, and a node in a connected safety network, ensuring that if something goes wrong, help is already on the way, and ideally, preventing that something from going wrong in the first place.

Embracing the Tech Culture Shift

Introducing AI and other high-tech tools to construction sites isn’t just a technical endeavour, it’s a human one. Construction has long been seen as a traditional industry, sometimes resistant to change. It’s not uncommon to hear veteran supervisors say, “I trust my 30 years of experience over a computer.” And many workers initially viewed wearables or cameras as a “Big Brother” intrusion, worried that management would use them to monitor every move or assign blame. However, a significant cultural shift is underway. As the benefits of these innovations become evident and new generations enter the workforce, crews and site managers are increasingly warming to technology as an ally rather than a threat.

Part of this shift is driven by demographics and talent dynamics. Younger professionals, who grew up with smartphones and automation everywhere, expect their workplaces to leverage modern tech. In a recent survey across industries, half of workers under 25 said their field’s approach to adopting new tech affects their career growth, far more than older workers felt the same. Yet construction was ranked the least technologically competent sector out of ten studied, coming in dead last behind even traditionally low-tech fields like restaurants. This reputation has consequences.

“Companies that fail to invest in workplace technology or provide training risk losing young talent to competitors that are more forward-thinking and committed to innovation,” warns Laurent Charpentier, CEO of tech firm Yooz, which conducted the survey. In other words, if construction wants to attract and retain the best people, it must shed its tech-averse image. Forward-looking contractors recognise this. They are not only adopting safety tech, but also actively marketing their jobs to recruits as being high-tech and innovative. It’s a savvy move: show that you value both safety and modern skills, and you become an employer of choice for the next generation of builders.

For those already on the jobsite, seeing is believing. Early scepticism about, say, wearing a sensor vest often fades when that vest issues a heat warning that prevents a hospitalisation, or when a co-worker’s life is saved because their fall was instantly detected by a smart hard hat. Success stories circulate through the crew grapevine. Over time, workers begin to take pride in using the new gear, it becomes a badge of a progressive, safety-first culture.

Many companies have found that involving workers in the rollout of tech is key: they appoint tech “champions” on crews to gather feedback, and they are transparent about what data is collected and why. For instance, a contractor might explain that helmet trackers are there to ensure everyone gets out safely in an emergency, not to check how long your tea break was. Building this trust is crucial. It echoes Brett Burkhart’s approach of sharing sensor data with the crew to collectively spot hazards, rather than using it as a surveillance tool. When workers understand that tech isn’t there to punish but to protect, acceptance soars. In fact, some wearables are now seen as extensions of standard PPE, just as one wouldn’t work without a hard hat, many are happy to clip on a smart band that could alert medics if they collapse.

Site managers and foremen are experiencing their own learning curve. A tablet-toting supervisor who can review safety AI alerts or drone footage of the site in real time is far more effective than one relying on gut feel alone. But that supervisor might need training to interpret the new data or to trust AI’s judgment. Investment in training the management level is paying off. Rather than replacing human judgment, the best firms empower their people to use tech as an enhancement to their expertise. For example, if an AI alarm sounds about a potential trench collapse risk, a savvy manager will investigate and reinforce the trench, even if their initial instinct didn’t catch the issue. Over time, even old-school bosses acknowledge that these systems often spot what humans miss. And with near-miss and incident data being logged impartially, safety meetings have become more about solving problems than pointing fingers.

Interestingly, the push for tech acceptance is also coming from clients and regulators. Some government bodies and project owners are beginning to mandate the use of certain safety technologies on high-risk projects. There are already discussions in parts of Europe about requiring proximity sensors on heavy equipment and connected worker devices in large infrastructure jobs. This top-down pressure solidifies the cultural change, so wearing a sensor or following AI guidance is part of compliance, it rapidly becomes the norm. What helps is that the tech has matured to be more user-friendly. The latest wearables are lighter and more comfortable (sometimes the worker forgets they’re even wearing a device). Interfaces have gotten simpler; many drones and AI platforms now present information in easy-to-read mobile apps rather than dense reports. As a result, even those who were initially intimidated by “fancy gadgets” are finding them as straightforward as using a smartphone.

The construction industry is by no means 100% sold, there are certainly still those who grumble about “robots taking over” or the hassle of new procedures. But the tide has clearly turned. Tech adoption in construction has roughly doubled in recent years, and crucially, the mindset is shifting from reactive to proactive safety. No longer is technology seen as a necessary evil; increasingly, it’s viewed as the path to ensuring everyone on site can do their job more easily and go home unharmed. The conversation has moved to how fast firms can implement new solutions, not whether they should. And as that cultural shift deepens, it paves the way for even more innovation to be welcomed on site.

Protecting Workers on the Move

Not all construction work happens off the beaten path, a significant portion takes place on or near roads, where traffic itself poses a lethal threat. Road construction and maintenance crews face the unique danger of live vehicles whizzing past just cones or barriers away. Here too, technology is raising the bar for safety with an array of high-tech road safety equipment and systems designed to safeguard both workers and drivers. These innovations range from intelligent traffic control devices to wearables that specifically shield highway crews.

One major advancement is the deployment of Smart Work Zones (SWZs) on highways. These use intelligent transport systems, think radar sensors, connected message signs, and automated flagging devices, to manage traffic dynamically through work areas. Unlike static signage, a smart work zone can detect when traffic is suddenly slowing or queuing and then automatically reduce speed limits on electronic signs or warn drivers via radio of upcoming stops. States like Texas and Iowa have piloted SWZ setups and reported promising safety improvements.

By smoothing traffic flow and giving drivers real-time information, SWZs aim to eliminate the sudden braking or last-minute lane changes that often cause work zone crashes. Some systems even employ portable intrusion alarms at the zone perimeters, essentially electronic tripwires that trigger flashing lights and sirens if an errant vehicle breaches the work zone boundary. This can give workers precious seconds of warning to get out of the way. Considering that the majority of work zone fatalities are vehicle drivers or passengers themselves (often from losing control on approach), these smart interventions protect everyone on the road.

For the workers on site, specialised safety tech is acting as a last line of defence. Wearable devices adapted for road crews include vests with built-in GPS and collision sensors that vibrate or alarm if a vehicle is detected speeding towards them. Imagine a highway flagger with a smart vest that starts buzzing if a car fails to slow down, it’s an urgent cue to look up and move. In some pilot programs, workers also carry small panic-button transponders; if they see a vehicle about to crash into the zone, one press sends an immediate signal that activates all the portable alarms at once, essentially shouting to everyone: “Danger, incoming!”

Additionally, geo-fencing technology is being used to automatically kill the throttle of heavy machinery when a human is too close. If a worker inadvertently steps behind a reversing dump truck, a geofence system can detect the worker’s tag and brake the truck before a tragedy occurs. These systems create virtual safe zones around equipment, part of the “connected worker, connected machine” approach.

Even standard road safety gear is getting smarter. Traffic cones and barricades can now come with blinking IoT beacons that relay their status and location to a central system. If a cone is hit or displaced, an alert can notify the site manager to replace it (maintaining the integrity of the safety setup). On the highways of the near future, “smart cones” might even communicate with approaching smart cars, so that autonomous or connected vehicles automatically slow down when they “read” the digital signal of a work zone marker. Meanwhile, advanced warning lights used on work trucks are being outfitted with sensors that gauge when a vehicle is approaching too fast, then intensify their flash pattern to grab the driver’s attention earlier.

An exciting development in road safety is the use of drones for overhead surveillance of work zones. From high above, drones give safety coordinators a live bird’s-eye view of both the site and oncoming traffic. They can quickly spot hazards like motorists veering towards barriers or workers standing in risky spots and relay that information instantly. Drones can also help manage traffic flow by monitoring congestion over a stretch of road and allowing supervisors to adjust signage or lane closures proactively. And in the event of an incident, an overhead drone video can greatly aid in debrief and investigation, leading to better preventive measures.

The combined impact of these high-tech road safety measures is significant. While work zone accidents remain a serious concern, with work zone fatalities up 50% over the last decade in some regions, the hope is that widespread adoption of technology can reverse the trend. Some early successes are heartening. For example, after adopting a smart work zone system with automated speed enforcement and warning alerts, one state’s transportation department noted a meaningful drop in crashes and zero fatal accidents in those monitored zones for the season. And as autonomous vehicles eventually become more common, the infrastructure being put in place now (connected signs, smart cones, etc.) will enable them to navigate work zones more safely than human drivers typically do.

High-tech road safety equipment, in essence, is about creating a buffer of intelligence around inherently dangerous work, slowing down the chaos, lighting up the dark spots (sometimes literally), and giving those on the ground a technological shield against the unforgiving realities of traffic. For highway workers and motorists, these innovations could be the difference between a close call and a calamity.

Building a Safer Future

From AI algorithms that flag a hazard before anyone gets hurt to VR headsets that train rookies in realistic scenarios, technology is profoundly reshaping construction safety for the better. Perhaps most importantly, it’s doing so by keeping the human at the centre, protecting the worker, augmenting the manager, and empowering the trainee. The cultural change on sites, where crews increasingly embrace gadgets as part of their standard kit, shows that these tools are shedding their novelty and becoming the new normal.

Firms investing in smart safety tech are seeing fewer accidents, lower costs, and a more engaged workforce. Policymakers and industry leaders are taking notice, supporting innovations that promise to save lives in an industry that has long been among the most dangerous.

The horizon is bright with possibilities. As sensors get smaller and AI algorithms get smarter, we may soon see “safety AI” predicting accidents before they ever occur, by analysing complex data from weather to worker fatigue to project schedules. Imagine a system that knows, based on millions of data points, that a certain lift has a high probability of failing today unless a precaution is taken, and then warns the crew in the morning meeting.

Trials are already underway with AI models that analyse site photos and automatically detect hazards or compliance issues in real time, essentially performing automated safety inspections. On the training front, the metaverse looms, fully interactive 3D worlds where entire crews across the globe could practice a coordinated build or emergency response together, as if in the same space.

Crucially, each innovation reinforces the ultimate goal: that every construction worker goes home safe and healthy at the end of the day. Technology is helping the industry inch closer to the aspirational goal of Zero Harm on sites. A decade ago, such a goal might have sounded utopian given the inherently risky nature of construction. But as AI and smart devices take on the heavy lifting of hazard monitoring and accident prevention, that goal is looking more realistic. It’s telling that many construction companies now talk about safety in the same breath as schedule and budget, a core project parameter to be optimised with the best tools available, not an afterthought. In boardrooms and break rooms alike, the conversation has shifted to “how can tech help us do this safer?”.

There will always be new challenges, and the industry will have to ensure that technology itself doesn’t introduce complacency or new risks (such as over-reliance on automation). But if the current trajectory is any indication, construction in the coming years will be a very different place: one where AI watches our backs, our equipment looks out for us, and our training happens in worlds we once only dreamed of.

The bricks and steel of construction might not have changed for centuries, but the brains on the jobsite, human and artificial, certainly have. Together, they are building a future of construction that is not just smarter and more efficient, but fundamentally safer. And that is a foundation everyone can stand on with confidence.