Trimble and Vermeer Join Forces to Transform Solar Farm Construction

The race to deliver renewable energy infrastructure is gathering pace, and solar farms are right at the heart of the global shift.

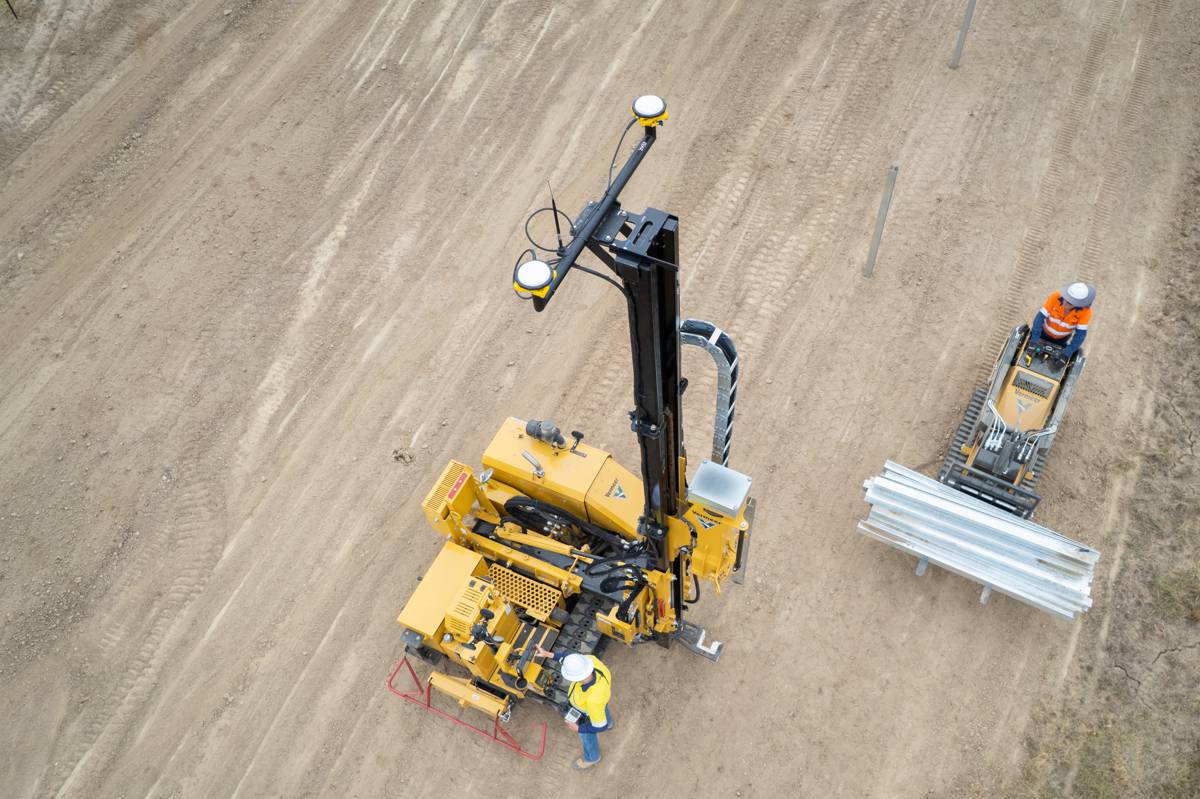

In a move set to reshape how these projects are built, Trimble and Vermeer have integrated the Trimble Groundworks machine control system with Vermeer’s PD10R and PD25R remote control pile drivers. This partnership marks a decisive step towards automation, offering speed, accuracy and efficiency that could change the economics of solar deployment.

Smarter piling with fewer people

Traditionally, driving piles for solar installations requires a small crew, often two or three operators coordinating machinery and alignment. Now, with Trimble Groundworks, a single operator can manage the entire task remotely. The system automatically positions the pile driver according to the project plan, adjusts its movements, and ensures each pile is driven to the correct depth. The benefits are clear: faster installation, reduced labour requirements, and less operator fatigue.

Ed Savage, lead product manager at Vermeer, highlighted the shift: “With the boom in energy requirements around the world, many energy companies are looking to solar to help them meet both economic and emissions goals. Leveraging Trimble machine control technology with Vermeer pile driving technology has the capability to change the way solar farms are built. Now, driving piles requires minimal operator inputs and can increase the speed and accuracy of solar farm construction.”

Tackling global energy challenges

As nations seek to balance energy security, decarbonisation and affordability, solar power has become one of the fastest-growing sources of electricity worldwide. The International Energy Agency (IEA) forecasts that solar will account for nearly two-thirds of global renewable capacity expansion by 2030. But scaling up requires new approaches to construction. Automated piling, like that offered by Trimble and Vermeer, addresses one of the most time-consuming and labour-intensive aspects of solar farm development.

Automation in piling not only speeds up installation but also helps standardise quality. With fewer variables dependent on human control, the risk of misalignment or uneven driving is reduced. This translates into more reliable solar arrays, quicker project completion and lower overall costs—factors that investors and developers watch closely.

Boosting productivity through digital integration

The integration doesn’t stop with machine control. Project managers can connect the system to Trimble WorksManager, a cloud-based platform providing real-time reporting on production and quality. Having live data at their fingertips allows managers to troubleshoot on the fly, monitor progress and maintain a consistent piling rate. In an industry where delays can rapidly escalate costs, the ability to track operations in real time provides a critical edge.

Elwyn McLachlan, vice president of civil solutions at Trimble, explained the broader significance: “The combination of machine control and remote control pile drivers represents the next step on the road to autonomy and has the potential to vastly improve worker safety, productivity, speed and accuracy on solar projects. Together, Vermeer and Trimble are changing how projects are completed and can improve the process of solar farm construction for the benefit of our customers and of our planet.”

Safety and sustainability gains

Worker safety remains a central concern on large construction sites. By reducing the need for multiple operators in close proximity to heavy equipment, remote-controlled systems help minimise risks. Operators can work from safer distances, focusing on precision rather than manoeuvring machinery in challenging terrain. Less operator fatigue also translates into fewer mistakes and accidents.

From a sustainability perspective, automation improves efficiency, meaning projects can be delivered faster with fewer resources. This directly supports global climate goals, as every megawatt of solar capacity deployed more quickly accelerates the transition away from fossil fuels.

Availability and market impact

The Trimble Groundworks system is now available globally for Vermeer PD10R and PD25R pile drivers through the SITECH distribution network. SITECH, already well-established in the heavy civil and construction markets, brings the reach needed to scale adoption across diverse regions.

For solar developers, this development could signal a new benchmark in project delivery. By reducing labour requirements, shortening construction timelines and cutting costs, automated piling technology may help drive greater investment in large-scale solar farms.

About the companies

Trimble has long positioned itself as a leader in connecting the physical and digital worlds, with technologies spanning positioning, modelling and analytics. Its solutions extend across construction, geospatial, transport and logistics, enabling greater productivity and efficiency.

Vermeer, known for its robust machinery, plays a vital role across industries ranging from agriculture to underground construction and environmental management. The company has built a reputation for durable equipment backed by strong dealer support networks, ensuring localised service across the globe.

Driving the renewable future

As the renewable energy sector expands, innovation in construction will be as important as breakthroughs in panel technology or storage solutions. Trimble and Vermeer’s collaboration is a practical example of how automation and digital integration can reshape workflows, reduce risks and accelerate deployment.

By bringing together precision machine control and tough, remote-controlled pile drivers, the two companies have created a tool that meets the demands of a fast-growing market. For governments, developers and contractors alike, this technology could prove pivotal in meeting ambitious renewable energy targets.