SCHOTT Develops Geometric Reflective Waveguides for Augmented Reality Innovations

International technology group SCHOTT has crossed a decisive threshold in Augmented Reality (AR) innovation by achieving serial production of Geometric Reflective Waveguides.

This manufacturing milestone is expected to reshape the future of consumer-grade wearable AR devices, particularly smart glasses. For the first time, these highly complex optical elements can be produced at volumes needed to support widespread commercial rollout.

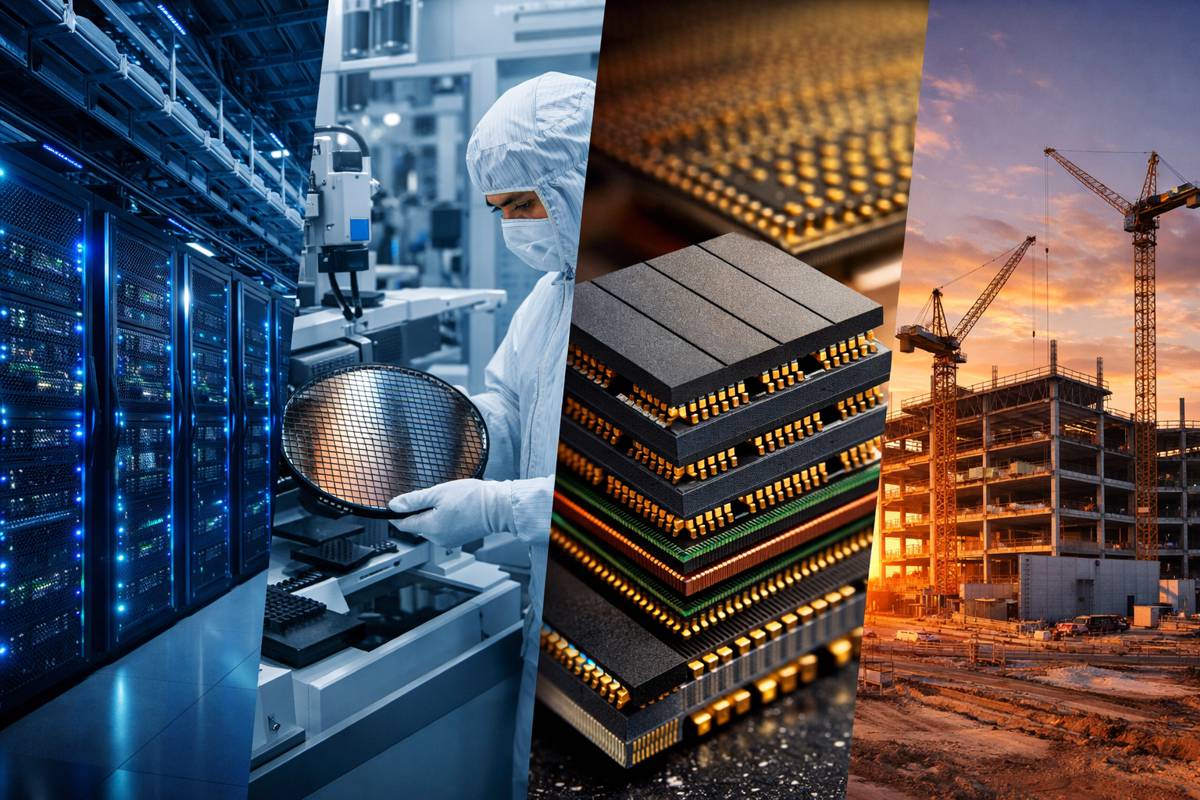

SCHOTT’s achievement stems from years of dedicated R&D and heavy investment in its global production infrastructure. By integrating optical glass production, wafer processing, vacuum coating, and waveguide assembly under one roof, the company ensures both quality and scalability. It has become the first player capable of delivering Geometric Reflective Waveguides at industrial scale.

Dr. Ruediger Sprengard, Senior Vice President Augmented Reality at SCHOTT, explained the significance: “This breakthrough in industrial production of Geometric Reflective Waveguides means nothing less than adding a crucial missing puzzle piece to the AR technology landscape. For years, the promise of lightweight and powerful smart glasses available at scale has been out of reach. Today, we are changing that. By offering Geometric Reflective Waveguides at scale, we’re helping our partners cross the threshold into truly wearable products, providing an immersive experience.”

Geometric Reflective Waveguides

At the heart of next-generation AR glasses, these waveguides deliver digital overlays into the user’s field of view with pristine clarity and unmatched energy efficiency. Unlike bulkier optical systems, they allow designers to create miniaturised, stylish, and comfortable glasses fit for daily wear. The ability to combine immersive visuals with sleek fashion-forward design is something the AR sector has long been chasing.

Compared with diffractive waveguides, Geometric Reflective Waveguides stand out in two key areas:

- Light efficiency: less power is needed to deliver bright, vivid overlays.

- Field of View flexibility: they are the only viable option for achieving wide FoV in AR glasses.

This combination is what makes them the leading contender for powering the next generation of consumer and enterprise-grade AR wearables.

A platform for immersive experiences

SCHOTT’s Geometric Reflective Waveguides were co-developed with its strategic partner Lumus, an established name in AR optics. Together, the companies have created a platform that supports a wide field of view range, ensuring immersive experiences without compromising comfort. This advancement provides device manufacturers with an opportunity to expand visual boundaries, integrating digital content seamlessly into everyday environments.

The technology’s ability to combine wide FoV with high efficiency is expected to accelerate adoption in industries beyond consumer electronics, including defence, industrial training, healthcare visualisation, and design engineering.

Scaling up: global facilities and investments

Mass-market readiness has only been possible due to SCHOTT’s substantial investment in advanced processing infrastructure. The company recently expanded its state-of-the-art facilities in Malaysia, enhancing wafer processing and optical coating capabilities. By doing so, SCHOTT ensures rigorous process control and consistent quality, both critical for meeting the demands of high-volume AR device production.

With more than 140 years of expertise in optical glass and processing, SCHOTT has leveraged its heritage to overcome the hurdles that previously hindered AR scalability. The new production capacity is seen as a strategic enabler for AR device manufacturers aiming to deliver stylish, lightweight products at competitive price points.

Heritage meets innovation

Founded in 1884 and headquartered in Mainz, Germany, SCHOTT has built a reputation for translating deep material science into practical applications. Its legacy includes flexible glass used in foldable smartphones, glass-ceramic substrates for the world’s largest telescopes, and laser glass for nuclear fusion research. With over 17,400 employees in more than 30 countries, the company continues to shape technology landscapes from healthcare and aerospace to consumer electronics and astronomy.

The Carl Zeiss Foundation, SCHOTT’s sole shareholder, reinvests company dividends to promote science and research. This ownership structure underpins SCHOTT’s dual mission: advancing innovation while supporting global scientific progress.

Commitment to AR industry leadership

Beyond Geometric Reflective Waveguides, SCHOTT offers complementary solutions such as the RealView® range of diffractive high-index glass wafers. Together, these products position the company as a one-stop provider for AR optics, giving device makers the flexibility to choose the technology best suited to their application.

SCHOTT’s long-term commitment to the AR sector reflects a broader trend: the push to merge digital information with physical reality in ways that are practical, comfortable, and scalable. By removing one of the biggest production barriers, SCHOTT has effectively unlocked a new era for AR wearables.

Looking ahead with confidence

The commercialisation of Geometric Reflective Waveguides is expected to catalyse a wave of new AR products over the coming years. For consumers, this means stylish glasses that don’t compromise on performance. For manufacturers, it marks the availability of a scalable, proven optical solution ready for integration. And for the wider AR ecosystem, it signals that the long-awaited breakthrough in wearable optics has finally arrived.

As SCHOTT’s Dr. Sprengard highlighted, the company’s achievement is not just about mass production but about enabling a vision that has been out of reach for too long. With its innovation-driven culture, global infrastructure, and unwavering focus on quality, SCHOTT is poised to remain a cornerstone of the AR revolution.