Cementing a Greener Future with Low-Carbon Concrete

Concrete is literally the foundation of modern civilisation, but it comes with a hefty climate cost. The production of cement, the key ingredient in concrete, emits an estimated 7-8% of global CO₂ each year, making it one of the single largest industrial contributors to greenhouse gases. To put it in perspective, “If the cement industry were a country it would rank as the world’s third largest emitter of greenhouse gases,” notes Eric Miller, an energy policy director at NRDC.

Faced with this outsized carbon footprint, the construction industry is under mounting pressure to clean up concrete’s act. That’s where low-carbon concrete comes in, promising to significantly cut emissions without undermining the strength and versatility that have made concrete the world’s most-used construction material (second only to water by volume). But making the leap from traditional Portland cement concrete to its low-carbon alternatives is no small feat. It’s a story of innovation, inertia, and increasingly, imperative change.

Concrete’s Heavy Carbon Footprint

Why exactly is concrete such a climate culprit? The answer lies in cement, the powder that binds sand and gravel into concrete. Manufacturing Portland cement involves heating limestone and clay to around 1,450°C in kilns. This energy-intensive process not only guzzles fuel (often coal or gas), but also triggers a chemical reaction (calcination) that releases huge amounts of CO₂ from the limestone itself. For every tonne of cement produced, roughly an equal tonne of carbon dioxide is emitted. Multiply that by the four-plus billion tonnes of cement made annually, and you get an enormous carbon problem.

On top of that, demand for concrete keeps rising worldwide. Rapid urbanization in developing regions means more buildings, roads, and infrastructure, and thus more cement. By 2050, global cement production is projected to increase by 30-50% if business continues as usual. Meeting climate targets, however, calls for the opposite trajectory. The Paris Agreement goals imply the concrete and cement sector must reach net-zero emissions by 2050, with a significant 16% cut by 2030.

The good news is that concrete’s carbon footprint can be dramatically reduced. In fact, forms of low-carbon concrete have existed for years. Using alternatives to ordinary Portland cement, such as industrial by-products or novel binders, can slash emissions per cubic meter of concrete by anywhere from 10% to over 50%. The challenge is that traditional concrete is a tried-and-true material; builders know exactly how it behaves, and it meets strict standards. To displace such an established product, low-carbon concrete must perform just as well (or better) on key metrics like strength, setting time, and cost.

What Is Low-Carbon Concrete?

In simple terms, low-carbon concrete is concrete that is formulated or produced in ways that generate significantly less CO₂ than conventional mixes. There are several strategies to achieve this:

Clinker reduction

Ordinary cement’s emissions mostly come from making clinker, the baked limestone nodules that are ground into cement powder. Low-carbon concretes often use less clinker by blending cement with other materials. Industrial by-products like fly ash (from coal power plants) or ground granulated blast furnace slag (from steelmaking) can partially replace clinker. These supplementary cementitious materials (SCMs) harden in a similar way to cement and can take up a sizable share of the mix. Modern “blended” cements with SCMs can reduce concrete’s carbon footprint by 20-50%. As Dr. Jouni Punkki, a concrete technology expert at Aalto University in Finland, points out: “Low-carbon concrete is by no means a new phenomenon. The technology already exists.” Using fly ash and slag in cement has decades of successful track record, the ancient Romans even used volcanic ash (a natural pozzolan) to make durable low-lime concrete.

Alternative binders

More radical approaches replace Portland cement entirely. Emerging cements include geopolymer binders made from fly ash or clay, alkali-activated cements, and novel chemistries that don’t rely on limestone at all. For example, start-up firms are developing cements that use electrochemistry to convert minerals at low temperatures, or that form calcium carbonate through microbial activity. These alternatives can cut CO₂ by 80% or more and even potentially avoid the kiln phase altogether. However, many are still in pilot stages and need further testing to match the reliable performance of traditional cement.

Carbon capture and utilization

Another route is tackling emissions at the source. Companies are beginning to deploy carbon capture technology at cement plants, trapping CO₂ before it leaves the smokestack. In Norway, a landmark project at the Brevik cement factory will soon start capturing ~400,000 tonnes of CO₂ per year, enabling production of one of the world’s first “net-zero” cements. On the utilization side, captured CO₂ can be injected into fresh concrete during mixing, where it mineralizes into solid calcium carbonate. This not only locks away CO₂ but can even strengthen the concrete. Dozens of projects have already used injected CO₂ curing (for instance, at Amazon’s new headquarters in Virginia) as a way to both sequester carbon and reduce cement needs.

Efficiency and mix design

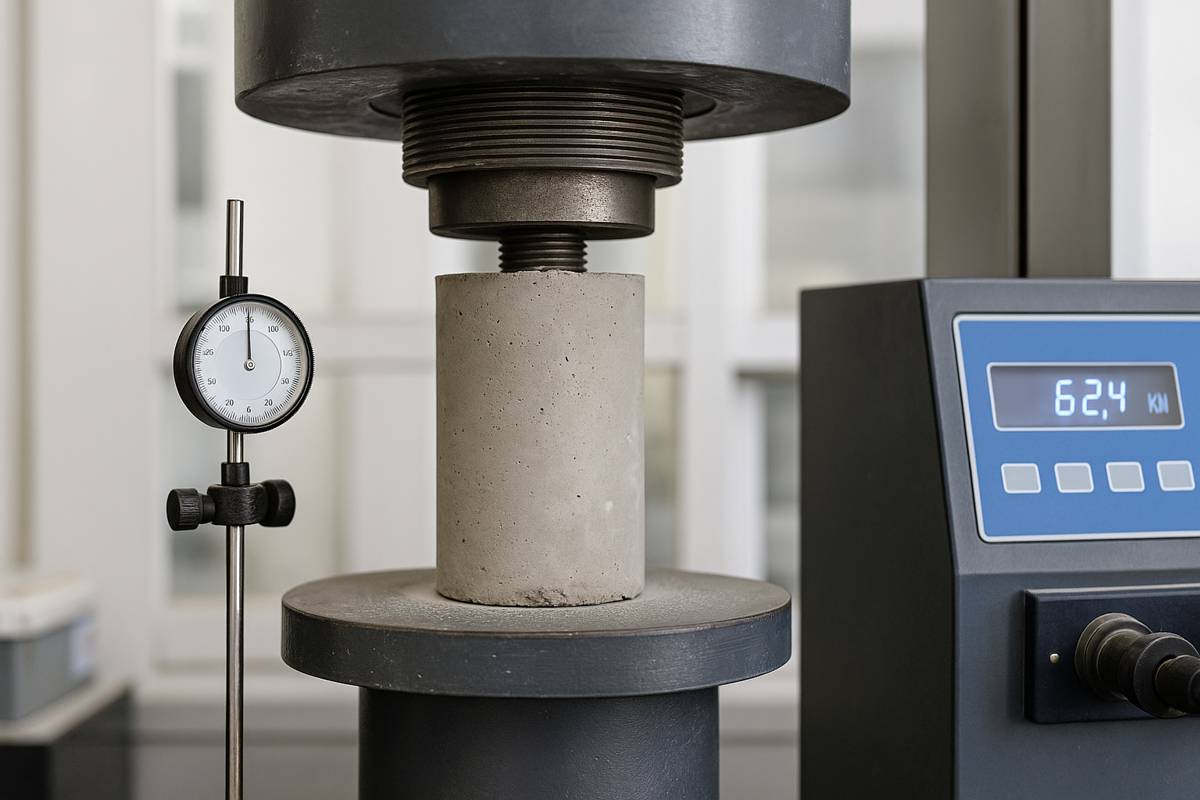

Often the simplest way to cut concrete’s carbon footprint is to use less cement for the same performance. High-strength concrete mixes, optimized aggregate grading, and chemical admixtures (like superplasticizers and accelerators) allow builders to achieve required strength with minimal cement content. In some cases, smarter structural design can reduce the volume of concrete needed altogether.

Reusing concrete elements or using recycled aggregates (as in “green concrete” initiatives) also contributes to lowering embodied carbon. Tools like the EC3 Calculator help project teams assess embodied carbon upfront and select the most sustainable options.

Slow Strength, Slow Adoption

If low-carbon concrete has so much promise, why isn’t every construction site using it already? The answer, in a word, is performance. One of the biggest hurdles for these greener mixes is that some of them gain strength more slowly than ordinary concrete. This is particularly true for concretes using high volumes of blast furnace slag or fly ash in place of clinker. While they eventually reach the same strength, their early strength development (within the first 24 hours of pouring) is sluggish compared to traditional mixes.

In many construction scenarios, time is money. Take the precast concrete industry, where components like wall panels and beams are cast in a factory. Precast manufacturers often strip the formwork and move a concrete element out of its mould the very next day after casting, typically requiring the concrete to reach a certain strength in 16-18 hours. With a low-carbon mix, that might take significantly longer. Dr. Punkki explains the issue: “Low-carbon blast furnace concrete has a slower strength development compared with the concretes made of conventional cements. This may significantly extend the production cycle and reduces the profitability of concrete element production.” In other words, if a precast plant has to wait extra hours (or days) for pieces to cure, its output and revenue suffer.

This slower curing isn’t just a factory problem; on construction sites, delayed strength gain can push back formwork removal, post-tensioning of slabs, or opening times for traffic on newly laid concrete pavements. Such delays can carry hefty costs. Thus, even if a low-carbon mix is technically workable, contractors may shy away if it doesn’t fit their fast-paced schedules.

Another concern has been code and standards compliance. Building codes are naturally cautious, since safety is paramount. Introducing new concrete formulas often means additional testing and certification to ensure they meet the required strength, durability, and longevity criteria. Engineers may need convincing to specify a greener concrete variant unless they are confident it will perform over decades. This conservatism can slow the acceptance of novel mixes.

Finally, availability can be an issue. Some supplementary materials like fly ash or slag are by-products of other industries (coal power, steelmaking) that are themselves facing decline in a decarbonizing world. In places where these materials are scarce, finding enough low-carbon material to blend into cement is challenging. Research is ongoing into alternative additives, calcined clays (like metakaolin), volcanic ash, agricultural residues, to broaden the menu of cement extenders. But each comes with its own supply chain and quality considerations.

Innovations Paving the Way

The race is on to overcome these hurdles, and the industry is responding with a wave of innovation and R&D. Concrete may be an ancient material, but it’s now at the forefront of green technology development. Some of the cutting-edge approaches making waves include:

Chemical Admixtures & Accelerators

New admixtures are being formulated to speed up early strength in low-carbon concretes. For example, special accelerators can be added to slag-rich concrete to make it set and harden faster, narrowing the gap with regular concrete.

These chemical tweaks, often proprietary mixes of catalysts and nanoparticles, help address the timing challenge without reverting to high-clinker cement.

Optimized Curing Techniques

Adjusting the curing environment can also boost early strength. Precast factories are experimenting with heat curing or steam curing low-carbon concrete elements to accelerate strength gain.

By carefully raising the temperature of the curing concrete (or even using microwaves in some trials), they can achieve overnight strength targets with mixes that otherwise would take much longer in normal conditions. This kind of controlled curing regime could allow greener concrete to slot into existing production schedules.

Carbonation Curing

As mentioned earlier, technologies like CarbonCure inject CO₂ into fresh concrete during mixing. Beyond the climate benefit, this process also increases early strength by causing calcium carbonates to form and bind the mix. In effect, the CO₂ acts as a hardening agent.

Such techniques mean a win-win: faster strength achievement and permanent carbon storage in one go.

New Cement Chemistries

On a more fundamental level, companies and universities are re-engineering cement itself. One example is LC³ (Limestone Calcined Clay Cement), developed by researchers as a blend of clinker, calcined clay, and limestone that can cut CO₂ by 40% while maintaining performance.

Another example is start-up Sublime Systems, which is developing an electrochemical cement production at ambient temperatures to eliminate kiln emissions. Meanwhile, bio-cementation research is looking at using microbes to precipitate calcite and “grow” a cement-like binder at normal temperatures. These breakthroughs are at varying readiness levels, but each could potentially be a game-changer if scaled successfully.

Digital Design Tools

The drive for low-carbon construction is also spurring change in how we design structures. Advanced software can optimize structural designs to use less concrete without sacrificing strength, for instance, by refining the shape of beams, slabs, and columns to put material only where needed. Architects and engineers are using topology optimization and generative design algorithms to trim excess concrete (and thus excess carbon) from projects.

Additionally, tools like the EC3 (Embodied Carbon in Construction Calculator) help compare material options and select mixes with the lowest carbon footprint early in the design phase. These digital solutions ensure that the first line of defence is simply using concrete more efficiently.

From labs to construction sites, these innovations are paving the way for a new generation of concrete that meets both performance and climate criteria. Around the world, forward-thinking projects are already deploying some of these methods, demonstrating that lower-carbon concrete is not just theoretical, but practical and achievable.

Finland’s LOIKKA Project

A prime example of industry and academia coming together to crack the low-carbon concrete puzzle is the LOIKKA project in Finland. Launched in 2022, LOIKKA is a joint initiative bringing together Finland’s cement and concrete associations, major construction firms, the national transport agency, and researchers at Aalto University. Their ambitious goal: to cut concrete construction emissions in Finland by 50% by figuring out how to make low-carbon concrete work seamlessly in practice, especially in precast production where the early-strength issue looms large.

Dr. Jouni Punkki is leading Aalto University’s contribution to LOIKKA. The research focuses on overcoming the initial strength challenge of slag-based low-carbon cement. One avenue is leveraging Aalto’s expertise in digital fabrication and monitoring, using smart sensors and automated measurements to closely track concrete curing in real-time. By better understanding the early strength gain, producers can know the earliest safe moment to remove forms or move elements, potentially squeezing more efficiency out of each production cycle.

“It is important to convince the concrete industry that investing in low carbon is worthwhile. We aim to ensure that the results of the project can be widely used by companies in concrete production and construction. Only in this way can climate emissions be reduced,” Dr. Punkki emphasizes. In short, the project isn’t just about lab experiments, it’s about proving to an entire industry that low-carbon concrete can be a viable, profitable norm.

Crucially, LOIKKA involves industry partners who will immediately apply the findings. One company at the table is Elematic Oy, a Finnish firm that supplies precast concrete factory equipment worldwide. As Jani Eilola of Elematic points out, the impact could be global: “Elematic’s customers have hundreds of factories around the world. If we can help them make the transition to low-carbon concrete, it will have a big impact on the climate.” From Europe to Asia, precast plants could adopt the improved processes and formulas coming out of LOIKKA.

Elematic is contributing by conducting full-scale test castings of low-carbon concrete elements on its production lines to see what modifications might be needed for equipment and routines. A key aim is to maintain the current mold turnaround times even when using slower-curing mixes. Eilola explains their approach: “With LOIKKA, we want to develop production technology in a way that maintains the current mould cycle. To speed up the introduction of low-carbon precast concrete elements for our customers, we are looking into alternate formulations of low-carbon concretes. Heat treatment of the concrete mix can also speed up drying and strength formation. The know-how we gain from this project can be shared with our customers around the world.”

By trailing different cement blends (for example, various proportions of slag, fly ash, or new accelerators) and experimenting with curing methods, the LOIKKA team is systematically narrowing in on solutions. The collaborative nature of the project means successes won’t remain proprietary secrets, they’ll be disseminated across Finland’s concrete industry and beyond. This collective approach is precisely what Dr. Punkki believes is needed. The Finnish construction market is relatively small on a global scale, but if it can demonstrate a workable low-carbon concrete model, it can inspire others. Indeed, Finland and the other Nordic countries have been early adopters of green construction practices.

“The Nordic countries are leading the way on these issues,” Dr. Punkki observes. The hope is that lessons from LOIKKA will inform European standards and perhaps even global best practices for precast concrete sustainability. If the project hits its targets by its conclusion, it could prove that cutting cement emissions in half is not only possible, but practical, even in a demanding factory environment.

Concrete at a Mega Scale

The scale of construction in Saudi Arabia’s NEOM project illustrates just how pressing the challenge of low-carbon concrete has become. With vast developments such as The Line, Oxagon, and Trojena, NEOM is expected to consume millions of tonnes of concrete over its multi-decade build.

For critics, this raises concerns over the embodied carbon of such an enormous development. Supporters argue it also presents an opportunity: by integrating low-carbon mixes, alternative binders, and carbon capture into the project from the outset, NEOM could become a global showcase of sustainable construction practices at scale.

If NEOM demonstrates how to use advanced concretes responsibly, it could influence best practice across the Middle East and beyond.

Climate Policy and Market Forces

While innovators tackle the technical challenges, policy and economics are also driving the shift toward low-carbon concrete. In the European Union, for example, the price of carbon emissions has risen steeply under the Emissions Trading System. Cement producers in Europe must purchase permits for each tonne of CO₂, and these permits traded at around €90-100 per tonne in recent times. At those prices, a cement plant emitting one million tonnes of CO₂ annually (about the scale of Finland’s cement industry) could incur €100 million in carbon costs per year, a huge new expense.

As free emission allowances are phased out and climate policies grow more stringent, such costs provide a powerful incentive for companies to lower their clinker use and adopt cleaner technologies. Dr. Punkki points out that ultimately these costs propagate through the construction value chain: “These costs will be passed on to concrete production and from concrete production back up the value chain. Ultimately, building owners and users will pay for this price increase. Therefore, low-carbon options give companies a competitive edge.” In other words, as carbon pricing makes conventional concrete more expensive, those who switch to low-carbon mixes sooner can deliver projects at lower cost and gain an edge in the market.

Governments are also using public procurement and legislation to accelerate change. In the United States, the federal government’s massive Inflation Reduction Act (IRA) of 2022 included several provisions to promote low-carbon materials. This included over $5 billion in funding and grants specifically aimed at encouraging the use of green concrete and steel in public projects. For instance, the General Services Administration received $2.15 billion to install low-carbon materials in federal buildings, and the Department of Transportation got $2 billion to reimburse highway projects that use low-carbon concrete and asphalt.

The law also invests in developing Environmental Product Declarations (EPDs) and labelling systems to clearly identify low-carbon construction products. All of this essentially puts government purchasing power behind greener concrete, helping create demand at scale and offsetting any cost premiums for innovative materials.

At the state and local level, numerous jurisdictions have rolled out their own rules, often dubbed “Buy Clean” laws or low-carbon concrete codes. For example, Marin County in California adopted the world’s first building code limiting concrete’s embodied carbon, effectively setting maximum cement content levels for concrete used in construction there.

New York State passed a law establishing low embodied-carbon requirements for concrete in state projects, and others like Colorado and New Jersey have introduced incentives (like tax credits or bid preferences) for concrete suppliers who deliver products with lower CO₂ footprints. These policies send a clear signal: there’s a growing market for low-carbon concrete, and being an early mover can bring rewards.

Private sector alliances are also propelling progress. Notably, at the global level, the First Movers Coalition, a group of major companies committed to buying emerging clean technologies, added concrete and cement to its focus sectors. Companies like General Motors, Microsoft, and others have pledged to procure a significant portion of their construction materials as low-carbon versions. Such commitments give producers confidence that investing in new low-carbon products will pay off with future sales.

The convergence of these policy and market forces means the landscape is rapidly changing. In the past, a concrete producer might not be able to justify investing in a new cement kiln technology or a complex mix redesign purely for environmental reasons. But now, with carbon costs biting and customers (including governments) asking for low-carbon options, sustainability is becoming synonymous with competitiveness. In many regions, it won’t be long before delivering high-carbon concrete is not just frowned upon but financially disadvantageous.

Laying Foundations for a Net-Zero Concrete Future

After centuries of little change, the concrete industry is unmistakably on the cusp of a green transformation. The technical solutions to decarbonize concrete are steadily falling into place, from smarter mix designs to breakthrough cements and carbon capture at plants, and they are being matched by a resolve from industry leaders, scientists, and policymakers to bring these solutions into the mainstream.

Dr. Punkki remains optimistic that the tipping point is near. He projects that low-carbon cement production could overtake conventional cement globally soon after 2030, and believes carbon-neutral concrete production is achievable by 2035 with the right mix of innovation and policy support. That timeline may be ambitious, but each year brings new progress and lessons learned.

What is clear is that concrete’s fundamental role isn’t going away, but its carbon emissions can and will go down. Around the world, pilot projects and real-life case studies are providing blueprints for how to build with far less carbon. Iconic examples range from high-rise buildings using green concrete mixes that halve emissions, to entire bridge projects constructed with cement-free concrete alternatives. As these examples multiply, confidence in low-carbon concrete will only grow.

The path to scale up is already being laid. Standards organizations are updating codes to accommodate new materials (for instance, allowing higher percentages of SCMs or approving novel cements). Large contractors are training their teams to handle different curing times and properties. Clients, from city governments to tech companies building new campuses, are setting specifications for low embodied carbon in concrete as a requirement, not an optional add-on. All these steps are helping integrate low-carbon concrete into the normal course of business in construction.

Guidance from organisations like the American Concrete Institute is also essential, ensuring that new materials and methods meet rigorous safety, durability, and performance standards. Their role in updating codes, publishing research, and training engineers worldwide helps accelerate the safe adoption of low-carbon concrete into mainstream practice.

There is, of course, more work ahead. The industry will need to ensure a reliable supply of alternative materials, and perhaps develop entirely new supply chains for things like calcined clay or captured CO₂. It must also remain vigilant on quality and long-term performance, sustainability should never come at the cost of structural safety or durability. But given the ingenuity on display, these challenges are surmountable.

Concrete has been called the most destructive material on earth in terms of environmental impact, but it is also the literal bedrock of development and modernization. Now, with climate change pressing, concrete is reinventing itself to be part of the solution rather than just part of the problem. The coming decades could see a renaissance in concrete technology, one that our great-grandparents (who mixed cement, sand, and stone with little regard for CO₂) would hardly recognize. From ultra-efficient skyscraper designs to smart highways that sip carbon, tomorrow’s infrastructure will rest on a new recipe: mixing the time-tested strength of concrete with the urgency of climate action.

If there’s one takeaway, it’s that low-carbon concrete is no longer a novelty, it’s the future. Each successful pour of green concrete, each new cement formula, each policy nudge is helping to cement a greener future for our cities and communities. The task now for construction professionals, investors, and policymakers is to push this transition faster and farther. By doing so, we can ensure that we keep building the world we need, but with concrete that doesn’t weigh so heavily on our planet.