Bobcat Machine IQ Telematics Passes 30,000 installs in Europe

Bobcat’s digital transformation is gathering pace across Europe as its Machine IQ telematics platform passes 30,000 connected units, marking a major milestone in the brand’s drive toward smarter, safer, and more efficient worksites. Launched in 2019, the proprietary system is redefining how owners, operators, and dealers manage and protect their fleets through real-time data and proactive maintenance insights.

Machine IQ provides a constant stream of critical information including machine location, usage, fuel efficiency, and maintenance schedules. By placing these insights directly in the hands of customers, Bobcat is helping them reduce downtime, enhance productivity, and make faster, data-driven decisions.

Tomas Plechaty, Senior Digital Program Manager at Doosan Bobcat EMEA, said: “Passing the 30,000 mark for Machine IQ not only underscores our team’s commitment to innovative, efficiency-centric solutions, but also reflects the genuine value that our connected machines deliver on the ground. With real-time data at their fingertips, Bobcat customers across Europe are using this technology to bolster security, drive productivity and improve decision-making.”

Unlocking Real-Time Intelligence

Machine IQ connects supported Bobcat models directly to the cloud, giving fleet managers the tools to act swiftly and decisively. It can be installed either at the factory or retrofitted by authorised dealers as an aftermarket upgrade, ensuring widespread compatibility across the Bobcat line-up.

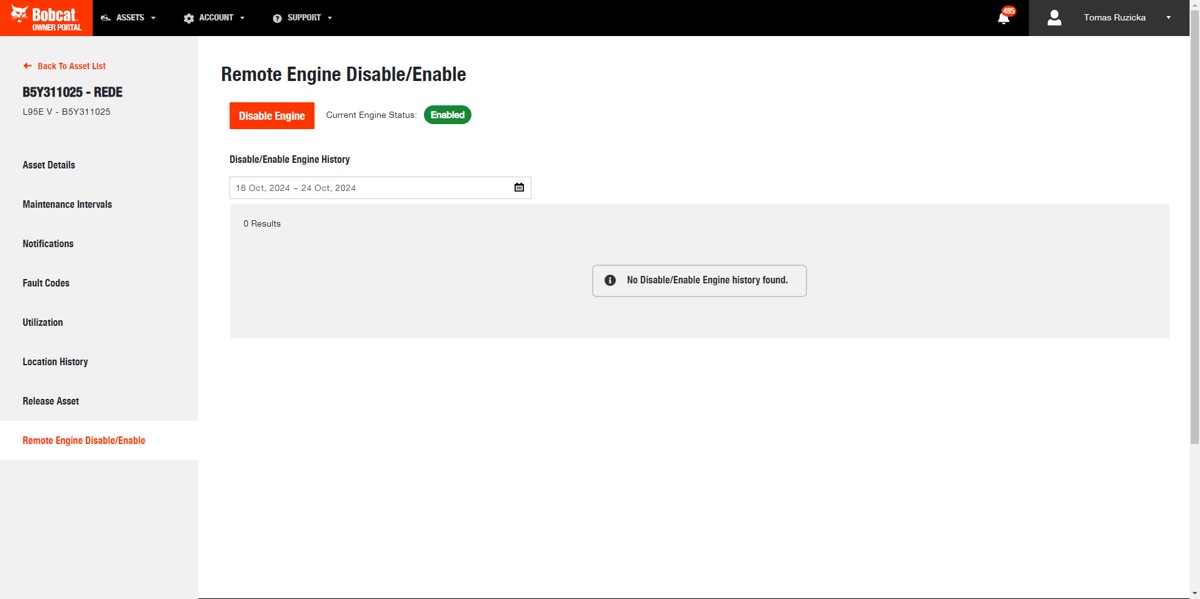

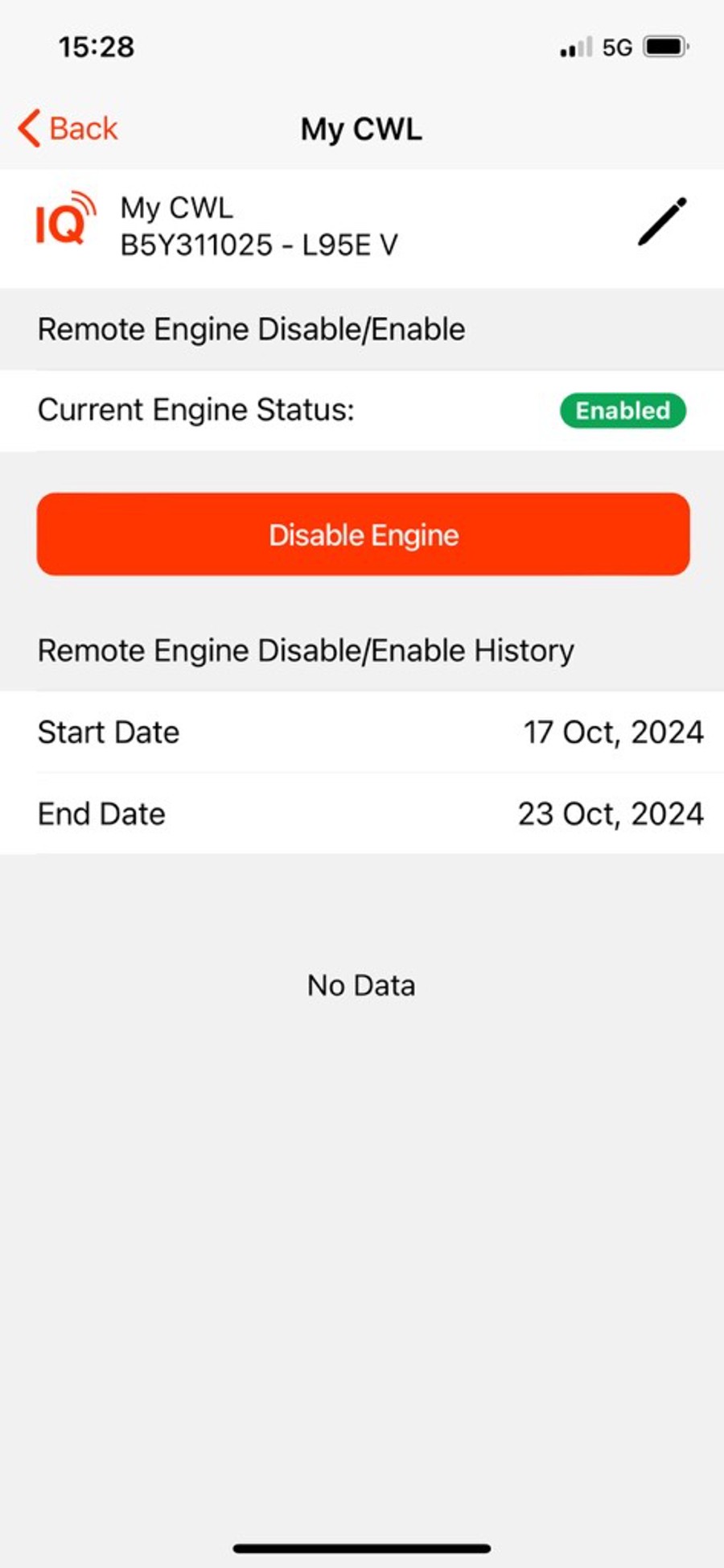

The Standard Package, available free for the first two years, offers essential capabilities such as maintenance tracking and machine grouping. For customers needing deeper insights, the Premium Package adds advanced utilisation reporting, fault code history, configurable notifications, and geofencing. The standout feature, however, is the Remote Engine Disable/Enable function, giving operators the power to remotely shut down or reactivate their machines, including skid-steer and compact track loaders, mini-excavators, compact wheel loaders, and telehandlers.

By integrating these capabilities, Bobcat’s Machine IQ gives users near real-time visibility into machine health and activity. It’s not just about knowing where equipment is, it’s about understanding how it’s performing and when it needs attention.

Strengthening Security and Reducing Risk

For contractors and rental companies, machine theft is an all-too-common headache. Machine IQ has emerged as a critical line of defence. With its geofencing and curfew alerts, customers can receive immediate notifications if equipment moves outside of authorised zones or hours.

In Belgium, for example, the platform played a pivotal role in recovering an E27z mini-excavator belonging to HA Terrassement. When the equipment disappeared from the company’s premises Bobcat’s dealer Vangaever NV was able to pinpoint its location using the Machine IQ system. Hans Vervloet, Aftermarket Manager at Vangaever NV, shared: “By accessing the machine’s most recent GPS data, we were able to provide the customer with exact coordinates, allowing the recovery of a valuable asset worth tens of thousands of euros in a matter of hours.”

In the UK, Grays Machinery Ltd has seen similar success. Director Sandy Gray noted how one client uses Machine IQ to protect a Bobcat S450 working remotely for extended periods: “The geofencing tools and live fault code alerts mean our customers can manage their assets confidently, even when machines are left on isolated sites.” The system not only strengthens security but also enables predictive maintenance, reducing costly surprises and extending equipment life.

New Remote Engine Control for Telehandlers

Building on user feedback and growing market demand, Bobcat has expanded the Machine IQ’s Remote Engine Disable/Enable function to include telehandlers. Accessible via the Machine IQ mobile app or Owner Portal, the feature lets users disable a machine’s engine remotely in case of theft or misuse, or re-enable it once recovered. This level of digital control is fast becoming a standard expectation in modern fleet management.

For fleet managers across construction, agriculture, and logistics sectors, such features deliver unmatched peace of mind. As theft prevention becomes increasingly important amid rising equipment costs, Machine IQ’s ability to disable stolen machines remotely represents a significant deterrent and recovery advantage.

Enhancing Maintenance and Uptime

Machine IQ’s ability to monitor and report faults in near real-time is transforming how dealers and operators approach maintenance. Rather than waiting for breakdowns, the platform enables proactive servicing that keeps machines running efficiently.

Kristina Bozhilova, Sales and Service Administration at Megatron EAD in Bulgaria, explained how Machine IQ is helping Rashev & Co manage its fleet: “The visibility we now have into fuel consumption, fault codes, and service schedules helps us act faster and more strategically. We can identify and fix problems before they escalate, ensuring minimal downtime.”

With detailed diagnostics and maintenance tracking, dealers can provide targeted support and prevent small issues from snowballing into costly repairs. This kind of foresight directly impacts a contractor’s bottom line, helping crews work more efficiently and ensuring that machines remain assets, not liabilities.

Data-Driven Decision Making

Machine IQ’s data analytics capabilities are proving invaluable in a sector that thrives on performance metrics. By analysing trends in fuel use, idling time, and operational hours, managers can identify inefficiencies and fine-tune their operations.

Fleet operators can benchmark machine performance across projects, plan servicing around actual use rather than arbitrary schedules, and even assess operator behaviour. This growing emphasis on data-led decisions is changing how construction firms budget, bid, and maintain competitiveness in an increasingly digital marketplace.

Furthermore, integration with other Bobcat digital tools is laying the groundwork for a connected ecosystem where machines, dealers, and customers share insights seamlessly. These integrations will help Bobcat’s network respond faster to maintenance needs, reduce admin overhead, and improve machine uptime across fleets.

Continued Innovation and Future Outlook

Bobcat’s Machine IQ milestone is just the beginning. The company’s investment in digital innovation continues to expand, with plans to enhance the platform’s analytics, diagnostics, and user interface. For European customers, this means a more connected, efficient, and secure equipment ecosystem.

Plechaty added: “While my colleagues and I are delighted to have achieved this exciting milestone, we’re only just getting started. Machine IQ is a cornerstone of Bobcat’s innovation-first approach, and we will continue to invest heavily in connected capabilities, integrations and dealer support that empower our customers to accomplish more.”

Bobcat’s telematics journey mirrors the broader shift in construction toward digitalisation. By blending reliability with cutting-edge connectivity, the company is giving its customers tools to anticipate challenges and make smarter, faster decisions.

Building a Connected Future

Since 1958, Bobcat has built its reputation on empowering people to do more with less. From its pioneering skid-steer loaders to today’s advanced telematics and automation solutions, the company continues to push the boundaries of what’s possible in compact machinery.

Machine IQ epitomises this philosophy. It’s not just a telematics system, it’s a digital bridge between man and machine, redefining worksite efficiency for a new generation of builders and innovators.