How Xwatch Became a Global Force in Machine Safety

In a remarkably short time, Xwatch Safety Solutions has evolved from a small British start-up to a global leader in construction and rail safety technology.

Founded in late 2018, the company’s meteoric rise is a testament to its innovation, engineering excellence, and unwavering commitment to operator safety. Now proudly operating under the Hexagon banner, Xwatch stands as a beacon of British ingenuity in a competitive global landscape.

Making Safety Simple

When Xwatch first entered the market, the team shared over 140 years of combined experience in safety, engineering, and machine control. Their vision was clear: design intuitive, reliable systems that make safety effortless for operators and accessible across every job site. As Sales Director Dan Leaney explained: “Right from the start, we knew the industry needed something different, something built around the operator. We set out to make safety systems that were simple to fit, easy to use, and that genuinely made people’s working lives safer.”

The launch of the XW Series in 2019 marked a pivotal moment. These systems, offering height, slew, and rated-capacity indication (RCI), quickly became known for fast installation, proportional control, and ease of setup. Powered by CANbus technology and PLC architecture, the hydraulic soft-stop function reduced wear on both operator and machine. In a sector where reliability and simplicity can mean the difference between uptime and downtime, Xwatch struck the perfect balance.

Building Trust and Expanding Globally

By 2021, Xwatch had overtaken long-established UK competitors and begun exporting to Europe, North America, and Australasia. Designed and built entirely in the UK, each system carries a five-year warranty, a statement of confidence that resonated with customers. Today, the company’s safety systems are standard across fleets from industry giants including Flannery Plant Hire, Lynch Plant Hire, Plantforce, Explore Plant, M O’Brien, and Synergy Hire. OEM partners such as Hitachi Construction Machinery UK and Molson Group also fit Xwatch systems as standard.

Leaney attributes much of this success to listening: “We’ve achieved this by working closely with our customers. Our systems are developed from real site feedback, from operators, plant managers, and contractors. That’s where our R&D team excels, because they listen first and then engineer a solution that actually works in the field.”

The Team Behind the Technology

At the heart of Xwatch’s success is its close-knit team, headquartered in Wimborne, Dorset. Sales and Operations Manager, Jemma Dycer Hopkins, plays a vital role coordinating engineers, managing dealer relations, and overseeing rollout schedules. Collaboration defines the culture: software, hardware, and product specialists work seamlessly to meet the company’s rigorous standards.

Leaney credits this teamwork for the firm’s agility: “It’s very much a team effort. Everyone plays a key role, from design to installation to customer support. That mix of practical experience and technical skill is what keeps us ahead.” He adds: “We’ve built a culture where engineering and operations work hand in hand. That’s one of the reasons we can move from concept to delivery so quickly.”

A Catalyst for Innovation

In 2024, Xwatch became part of Hexagon, a global leader in digital reality solutions. The partnership has already accelerated research and development, enabling Xwatch to expand its footprint across construction, rail, and digital integration.

Among the most exciting outcomes is the introduction of EVC (Electronic Valve Control) technology, an evolution of Xwatch’s pioneering EHOC (Electric over Hydraulic Control). While EHOC set a new benchmark for seamless control between electronic and hydraulic systems, EVC takes things to the next level. It’s the first system capable of providing full safety control for machines with electronic hydraulics.

Launched at PlantWorx 2025 on the new Mk2 platform, EVC offers complete height, slew, and RCI management for electrohydraulic machines such as the JCB Hydradig and Caterpillar 320 and 323. The PL d-rated Mk2 also delivers faster installation, integrated telematics, and OEM display capability, a leap forward in managing digitally controlled machinery.

Dedicated Systems for Rail Safety

Xwatch’s innovation extends beyond traditional construction. The company recently introduced the XW5R, a rail-specific adaptation of its acclaimed XW5 system. Designed for road-rail vehicles and track-side operations, the XW5R complies with RIS-1530-PLT Issue 7 and EN 15746 standards, supporting Any Line Open (ALO) and Overhead Line Equipment (OLE) working.

Compact and easy to install, it combines height, slew, and RCI functions with configurable lifting modes for varying rail conditions. For contractors operating in challenging environments, the XW5R offers the confidence of compliant, reliable, and user-friendly safety control.

Connecting Data, People, and Safety

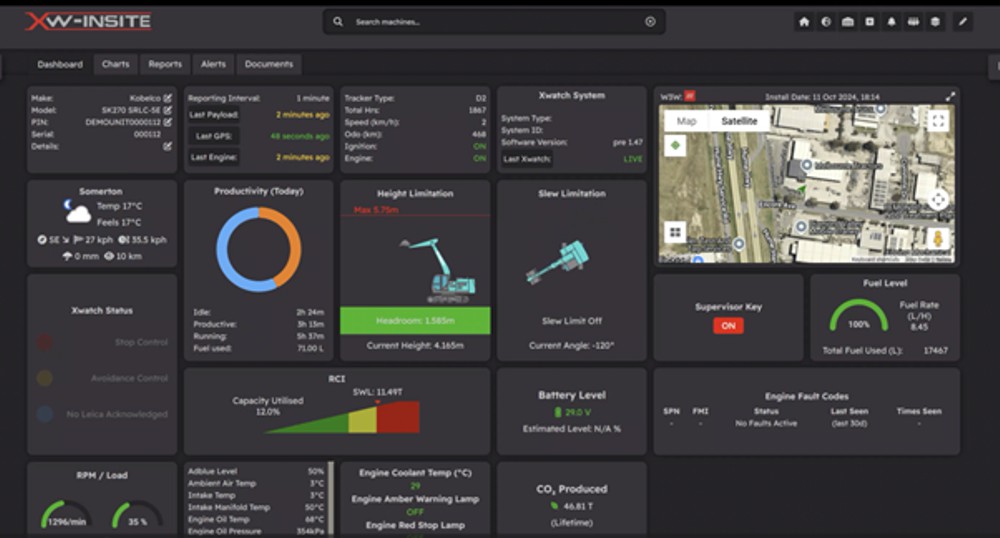

To complement its hardware, Xwatch developed XW-Insite, an advanced telematics and safety platform built in partnership with PVS Data. This cloud-based dashboard merges live machine data with Xwatch safety analytics, giving fleet operators real-time visibility across mixed-brand fleets.

Currently deployed by Hitachi Construction Machinery UK and integrated with the CTFleet Link® platform, XW-Insite delivers unparalleled insight into machine performance and operator behaviour. As Leaney explains: “Telematics has become integral to how we think about safety. It’s not just about what happens in the cab, it’s about understanding how machines are being used across a site or a fleet, so we can prevent issues before they happen.”

Collaboration with Leica Geosystems

Further innovation comes through collaboration with Leica Geosystems, also part of Hexagon. Together, the two firms developed the 3D Avoidance Zone solution, a world-first integration of Leica’s MC1 machine control and Xwatch’s safety systems. The system automatically halts or adjusts machine movement when approaching restricted zones, preventing potential collisions and improving safety in confined worksites.

At PlantWorx 2025, this breakthrough, along with the Mk2 platform, earned Xwatch the prestigious Safety Innovation Award, a fitting recognition of its engineering leadership.

Safety, Simplified and Smart

Seven years on, Xwatch remains anchored by the same philosophy that started it all: keep safety simple and effective. As Leaney reflects: “Seven years on, we’re still driven by the same purpose. To build safety systems that people actually want to use. It’s been a real team effort from day one – and we’re only just getting started.”

From its Wimborne base, the company continues to design and manufacture in the UK, leveraging British engineering talent while embracing global technology trends. The future looks bright, with Hexagon’s support, Xwatch is set to redefine the intersection of digital intelligence and machine safety.

A Safer Future Built on Innovation

As construction and rail industries evolve, so too does the demand for smarter, more connected safety solutions. Xwatch stands at the forefront of that transformation, blending innovation with practicality, and technology with trust.

The company’s commitment to operator-first design and seamless integration ensures one thing above all: that every machine, every operator, and every site remains safer, every single day.