Shape Memory Alloys Set to Transform Concrete Railway Ties

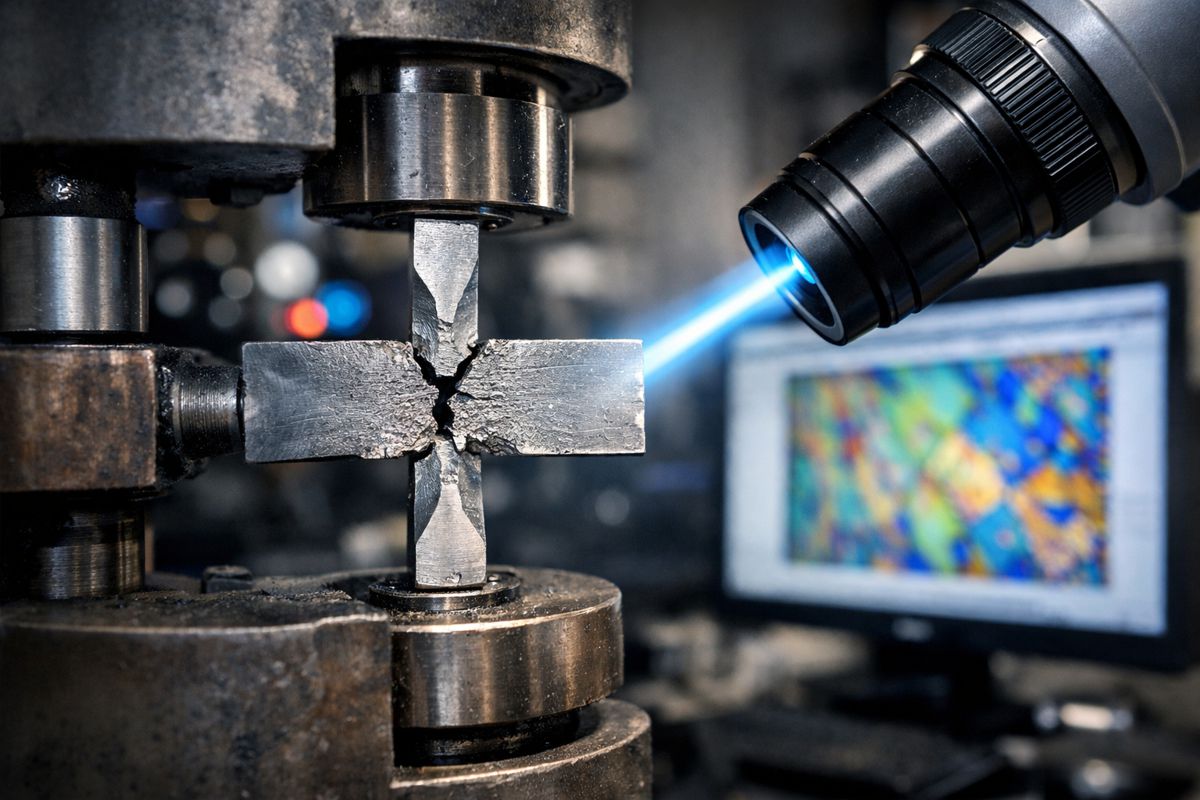

Concrete rail ties are the backbone of modern railway networks, securing rails in place and maintaining precise alignment under immense loads. However, as trains grow faster and heavier, these ties face relentless mechanical punishment. Fatigue, warping and cracking can creep in over time, creating safety concerns that, in worst cases, may contribute to derailments. Traditional prestressing methods help, but uneven pressures and shifting ballast still take their toll.

The study titled “Experimental Testing of Concrete Crossties Prestressed with Shape Memory Alloys” marks an important milestone in railway engineering research.

Researchers at The Grainger College of Engineering at the University of Illinois Urbana-Champaign are pushing the boundary of what rail technology can achieve. With pioneering work led by civil and environmental engineering professor Bassem Andrawes, a new tool has entered the field: shape memory alloys, or SMAs. These remarkable metals have a unique trick. After being bent or distorted, they return to their original form when heated. In essence, they offer a way for concrete rail ties to “self-correct” damage before it becomes dangerous.

“We’re doing something that I think is unprecedented in rail transportation engineering” said Andrawes. “We’re working with a commercial supplier of concrete rail ties to implement and test our designs. For our publication, we went beyond laboratory experiments and demonstrated compliance with rail industry standards. We’re very excited to continue our industrial partnership and develop a practical, working design.”

The Problem with Traditional Concrete Ties

Modern railways rely heavily on prestressed concrete ties. They contain pre-tensioned steel rods designed to counter heavy rolling loads. Over time though, variable stresses across the length of the tie and settling ballast can cause distortions and cracks. Once damage starts, maintenance becomes urgent and costly.

Prestressing cannot adapt to localised stress differences or shifting load patterns. The system is static, while rail environments are anything but. A dynamic solution is needed, one that responds to change in real time.

Enter Shape Memory Alloys

SMAs have long been an engineering fascination. Their ability to “remember” original shapes at a molecular level makes them ideal for self-healing structures. Twist them, bend them, stretch them, and they still snap back when heated.

Andrawes and his team saw an opportunity to harness this memory effect inside rail ties. Rather than rely solely on steel rods, SMA rods could be embedded within concrete ties and activated when deformation occurs. When heat is applied, the alloy contracts, gently pulling the concrete back to its designed geometry.

As Andrawes put it: “SMAs are examples of what we call ‘smart materials.’ You can deform them, twist them into wild new shapes, but they retain memory of their original state in the molecular structure. When you apply heat, they know to return to that state”.

The Key to Practical Deployment

To make the concept commercially viable, the SMA reinforcement has to be activated without embedding electrical hardware inside ties. Working with graduate student Ernesto Pérez-Claros, the research team selected induction heating. A time-varying electromagnetic field delivers the heat needed to activate the SMA, all without wires buried inside concrete.

This approach opens the door to real-world use, where maintenance teams can apply heat externally or automated systems could respond to deformation signals.

Putting Theory on the Tracks

Unlike many early-stage academic innovations, this research never stayed confined to the lab. In partnership with Rocla Concrete Tie, Inc., the team cast SMA-reinforced rail ties using real-world manufacturing processes. These ties then underwent rigorous testing in three phases:

- Casting commercial concrete ties with SMA reinforcement

- Laboratory tests measuring SMA length effects on performance

- Full simulated rail traffic loads

Not only did the prototypes meet industry requirements, they surpassed them. They exceeded standards set by the American Railway Engineering and Maintenance-of-Way Association (AREMA).

Andrawes reflected: “It was important to us that we actually make something that goes out of the lab and into practice… This is something that railroads can use, and we intend to guide it to the point where it can be adopted.”

Towards Full-Scale Rail Deployment

Next, the technology will enter advanced testing at the Federal Railroad Administration’s Transportation Technology Center in Pueblo, Colorado. Success there would mark a critical milestone toward industry rollout. With support from the U.S. Department of Transportation and the Transportation Research Board, commercialisation efforts are already underway.

Demand for smarter infrastructure is rising across North America and beyond. As national rail networks prepare for modernisation and expansion, innovations that raise safety while reducing maintenance cost hold compelling value.

Smart Materials in Global Infrastructure

Shape memory alloys are not isolated to rail. They are gaining traction across construction, seismic protection and aerospace engineering. Researchers worldwide are investigating SMA use in:

- Earthquake-resistant bridge bearings

- Adaptive building reinforcement systems

- Automotive actuators

- Spacecraft deployable structures

Infrastructure developers are particularly keen. From self-healing asphalt to intelligent concrete capable of sensing stress, next-generation materials are poised to transform global construction.

Why Intelligent Rail Infrastructure Matters

Rail remains the backbone of sustainable freight and passenger transport. As demand increases and networks age, maintenance demands rise sharply. Derailments linked to infrastructure wear not only cost millions but also pose life-threatening risks. Self-correcting rail ties could drastically cut risk while boosting service reliability.

Smarter materials align perfectly with national rail safety legislation and decarbonisation strategies. Lower maintenance needs mean fewer site interventions, reduced materials waste and extended infrastructure lifespan.

The rail sector stands at the cusp of a paradigm shift. By combining advanced metallurgy, adaptable design and scalable manufacturing partnerships, SMA-reinforced rail ties could become a defining innovation for future networks.

On Track for a Smarter Future

With real-world testing underway and industry collaboration already active, this breakthrough is more than a lab achievement. It represents a potential leap in how rail systems are engineered. Safer tracks, lower maintenance, and smart self-adjusting infrastructure hold huge promise for rail operators, passengers and freight carriers alike.

In an era calling for resilient, intelligent, and efficient transport systems, shape memory alloy-reinforced rail ties may well set a new benchmark for innovation in infrastructure engineering.