Live Retrofit in London Sets a New Benchmark for Sustainable HVAC Upgrades

London’s commercial real estate sector is undergoing a quiet revolution, and at its core sits a challenge shared across the capital: how to decarbonise complex, occupied buildings without grinding daily operations to a halt. As heat pumps replace fossil-fuelled chillers and retrofits take precedence over new-builds, the industry is learning that innovation in pipework and installation techniques matters just as much as high-efficiency plant.

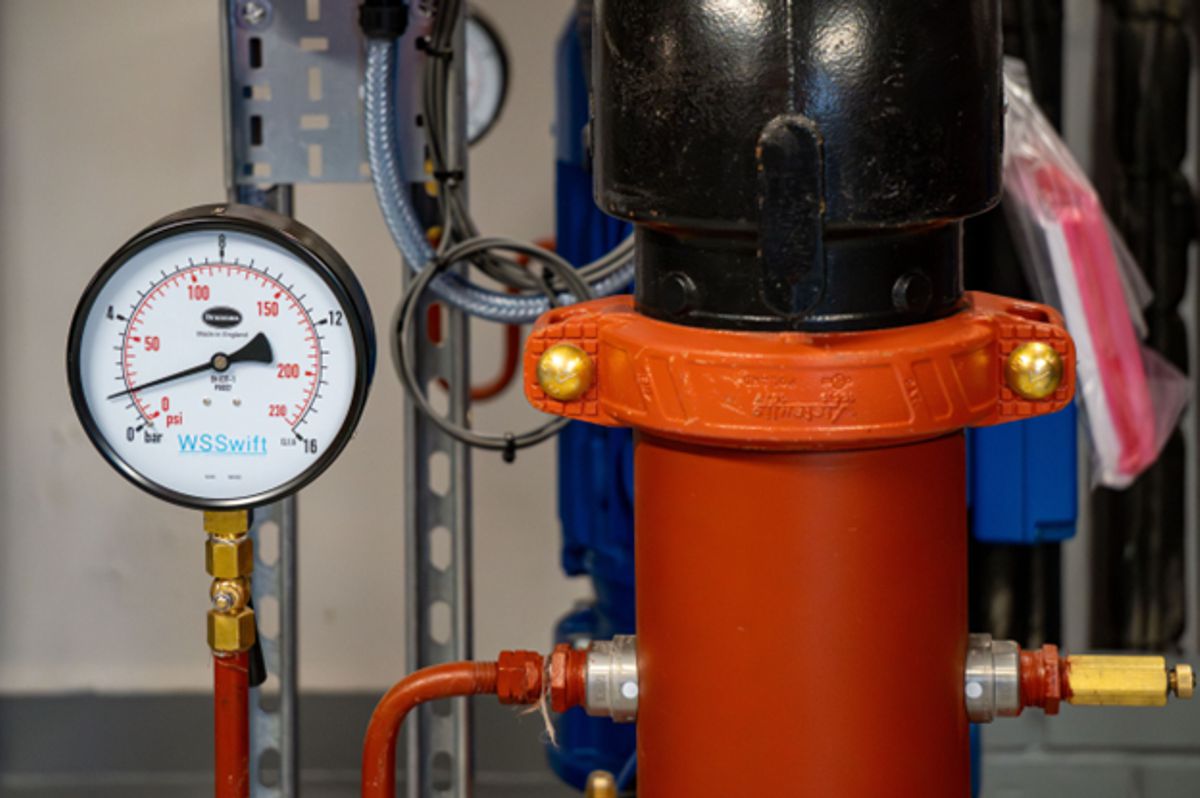

At 1 Stephen Street in Fitzrovia, that principle was put to the test. Mechanical, electrical and HVAC specialist WS Swift partnered with Victaulic to deliver a live HVAC upgrade in a fully occupied landmark building, replacing ageing chillers with advanced air-source heat pumps while ensuring business as usual for tenants throughout the summer of 2024. The result offers a blueprint for London’s next wave of energy-efficient building retrofits.

A city racing toward net zero

Decarbonising London’s built environment remains one of the capital’s biggest hurdles. According to the Greater London Authority (GLA), buildings account for 78% of the city’s greenhouse gas emissions. With London targeting net zero by 2030 and the wider UK aiming for 2050, attention has shifted sharply from new builds to retrofitting and electrification.

The GLA’s Accelerated Green Pathway projects 2.2 million heat pumps to be installed across London buildings by 2030. Meanwhile, the Carbon Trust estimates that improving existing building stock could cut emissions by up to 85% over the next decade.

Against this backdrop, live-occupied decarbonisation projects like 1 Stephen Street are becoming the new norm and a proving ground for contractors and suppliers.

Delivering a live retrofit without disruption

For WS Swift, the challenge wasn’t simply installing new heat pump, it was doing so without disturbing the daily life of one of Central London’s busiest multi-tenant buildings. Flame-free mechanical joining emerged as the critical enabler.

“The partnership with Victaulic allowed us to deliver an efficient solution tailored to the needs of the building and its tenants. The simplicity of the installation process, compared to flame-based pipe joining, helped us to stay on schedule and reduce the carbon footprint of the project” said Chris Rodwell, Mechanical Project Manager at WS Swift.

Welding was initially considered during planning; however, lengthy on-site hot works requirements, labour intensity, and safety constraints made it impractical for a live, fully occupied site. Instead, WS Swift leaned on Victaulic’s mechanical pipe joining system, a grooved connection method secured by couplings and bolts, eliminating the need for hot works, cutting installation time, and allowing flexible reconfiguration.

Victaulic supported the process through 3D modelling and VDC expertise. “During planning, we took our original drawings to Victaulic’s Virtual Design and Construction department. They converted our welded model into detailed 3D drawings which helped to visualise and optimise the piping design and mitigate any potential system clashes prior to installation” said Daniel Swift, Managing Director at WS Swift.

Flame-free installation also eliminated fire risks, a major advantage given the building remained in use throughout the upgrade.

Keeping tenants cool while heat pumps took over

A live HVAC retrofit in summer demands precision. The team couldn’t simply switch systems off; instead, temporary cooling systems ran in parallel, powered and connected using the same Victaulic technology.

“Multiple systems were running back-to-back to keep the building cool. As we shut down old chillers, we provided temporary cooling systems, all using Victaulic products as they are so adaptable, allowing the temporary system to be quickly disassembled and reconfigured at a new location, all using the same materials” Swift explained.

The approach allowed WS Swift to build elements of the plant room off-site and relocate them without interruption, a rare feat in live retrofit work.

Safety, sustainability and speed in one solution

Every element of the upgrade was designed to:

- Reduce on-site carbon and eliminate emissions from hot works

- Avoid disruption to tenants and operations

- Maintain cooling capacity throughout install

- Enable fast, modular installation

- Support maintenance and future changes

Victaulic’s grooved systems provided visual installation verification and required only basic tooling, enabling faster progress without specialist welders.

“Using Victaulic solutions means there is a big saving on time because their products are so much quicker to install. Minor alterations are very quick and easy to execute too” Rodwell added.

Victaulic also contributed to circular-economy goals through component reusability. Couplings can be removed and reused, easing future system upgrades and simplifying end-of-life recycling.

The wider retrofit picture

Victaulic has seen growing demand across the UK retrofit market, particularly in commercial and public sector buildings. Rising decarbonisation targets, asset life extension, and the push for all-electric HVAC systems are driving adoption.

“Decarbonising existing buildings in London is a critical step to meet net zero goals. We’re proud to support projects like 1 Stephen Street with innovative solutions that make retrofitting faster, safer, and more adaptable, while also reducing on-site emissions” said Ed Hamlyn, Technical Sales Engineer at Victaulic.

WS Swift echoed this shift in priorities. “Sustainability is at the heart of what we do. On this Stephen Street project, Victaulic solutions meant we were able to minimise emissions, reuse components, and support a circular economy, all while delivering a cutting-edge HVAC system” Swift said. “Decarbonising an existing building is far more complex than starting from scratch. This project shows how combining new technology with thoughtful planning can transform older spaces into sustainable, energy-efficient environments with little to no impact on building operation.”

According to the UK Green Building Council, deep retrofit investment could exceed £350 billion by 2050, with commercial offices among the highest-priority assets. London’s role as a global business hub makes scalable retrofit models essential.

Technology that supports operational continuity

Live retrofit success increasingly depends on:

- Modular installation systems

- Digital design and clash detection

- Safety-first installation planning

- Temporary system flexibility

- Circular material use

Victaulic’s installation-ready couplings and VDC support align closely with these needs, empowering contractors to deliver phased replacements without shutting down core building services.

The system’s ability to adapt mid-project is particularly valuable in older buildings with hidden constraints or evolving design requirements.

A reliable partnership for the future

With London’s push toward low-carbon building systems accelerating, WS Swift expects retrofit innovation to be business as usual rather than an exception.

“It’s easy to summarise, really. The key benefits for us partnering with Victaulic are the reconfigurability of its system, the fact products can be reused, the fact that there’s no welding, and no emissions on site, and that the products can be recycled at end of life bring great advantages to any decarbonisation jobs. This project is a testament to the power of innovative partnerships in shaping a greener future” Swift concluded.

Victaulic, founded in 1919, continues to reinvent piping installation and system design through mechanical joining solutions, innovation in modular construction, and digital engineering capabilities. With 5,500 employees, 55 facilities and customers in more than 140 countries, the business supports some of the world’s most complex industrial, infrastructure and commercial projects.

Building a more efficient future for London’s landmarks

The retrofit of 1 Stephen Street demonstrates how collaborative engineering, modern installation systems and a focus on operational continuity can help London upgrade its building stock without compromising daily life.

With millions of heat pumps, electrified energy systems and smart retrofits needed in the years ahead, lessons from this project are likely to echo across the capital. By proving that decarbonisation can be achieved in real-time, without disruption, Victaulic and WS Swift have set a new performance benchmark for sustainable upgrades in Britain’s urban centres.