Smart Technology Revolutionising the Foundations of Construction

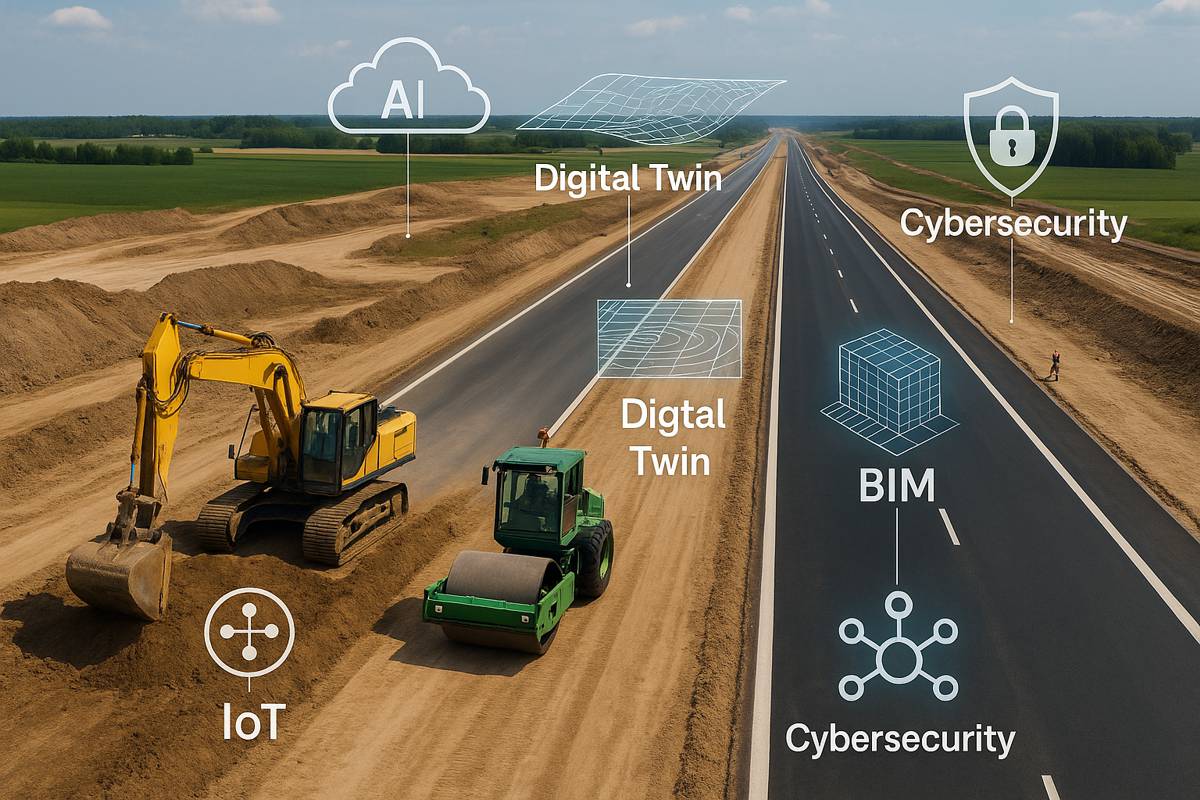

The construction industry is undergoing a profound digital transformation, blending traditional brick‑and‑mortar practices with cutting‑edge technology. From the earliest blueprints to the final brick laid on site, data and connectivity are driving a shift to “smart construction”. Sensors, artificial intelligence (AI), robotics and advanced modelling tools are enabling planners, engineers and site crews to work more efficiently and safely than ever. As one industry analyst noted, infrastructure is now “blending time‑honoured asphalt with cutting‑edge algorithms”. Modern highways and building projects alike are using real‑time data and virtual models to solve problems that steel and concrete alone cannot.

At the same time, these innovations are reshaping the very nature of project delivery. Gone are the days when construction relied solely on paper drawings and intuition. Today, “digital innovation goes hand in hand with progress”, ushering in an era of data‑driven decision‑making. Investors, policymakers and construction leaders are all taking note: smart tech is no longer a futuristic novelty, but a practical necessity for faster, safer and greener projects.

In fact, AI‑driven tools on site are already being hailed as potential life‑savers. Industry data shows roughly 20% of all workplace fatalities occur in construction, so every sensor and algorithm that can prevent an accident immediately pays off in human and financial terms. As our analysis below shows, AI, IoT, BIM, robotics and other technologies are revolutionising planning, design and on‑site efficiency, and cybersecurity is critical to protect this digital ecosystem.

Digital Twins and BIM

Effective digital construction starts long before the first digger hits the ground. Engineers and planners are increasingly relying on Building Information Modelling (BIM) and digital twins to create living, data‑rich blueprints of projects. Unlike traditional CAD drawings, BIM is “more than just a digital blueprint, it’s a shared digital environment where multiple stakeholders… collaborate and communicate throughout a project’s lifecycle”. This multidimensional modelling connects geometry, schedule (4D), cost (5D) and sustainability data (6D) into a single cohesive model. All parties, architects, engineers, contractors and clients, work from the same up‑to‑date information, reducing errors and rework.

Digital twins take BIM a step further by providing a live replica of physical assets. A twin is essentially a dynamic digital counterpart of a road, bridge or building that updates in real time as data pours in from sensors and project management systems. This unified model becomes “the foundation of smarter decision‑making,” enabling teams to simulate scenarios and optimise designs throughout a project’s life. For example, agencies can integrate environmental data, traffic forecasts or material performance metrics into the digital twin from day one. The result is a single context that brings together “environmental, structural, and operational data” for a holistic view. In other words, engineers can virtually drive on a future highway, test different designs or catch conflicts before a single beam is ordered.

Real‑world projects are already showing the payoff. In London, planners used advanced digital modelling for the Elizabeth Line to “determine how best to design this new line,” according to Bentley Systems Bibhuti Aryal. The simulation reduced vehicle traffic, cutting congestion and emissions, and delivering a faster, greener transit line. In Singapore, city‑wide digital twins allow urban planners to monitor development and infrastructure needs in real time. Even tendering and contracts are going digital: tender documents now include 3D models with embedded quantities and defect histories, so contractors bid on projects knowing exactly what they will build. As Aryal points out, integrating BIM and twin data means bids can’t hide “unknowns,” leading to more accurate estimates and fewer disputes.

Innovative organisations are making BIM central to their strategies. Bentley Systems, for example, has evolved its BIM tools (OpenRoads Designer, SYNCHRO) into open platforms that integrate AI and IoT. Their software pushes the project model to “consume data from other systems” and share information across disciplines. This ensures that if you’re designing, building or operating infrastructure, you contribute back to the same digital model. In practice, BIM and digital twins are streamlining everything from site feasibility to facility management, creating a 360‑degree view of the project at every stage. The takeaway for construction professionals is clear: robust, data‑driven models now underpin smarter planning, helping projects stay on track while optimising sustainability and cost.

AI and Data Analytics

Artificial intelligence is weaving through both the office and the work site, turning vast data sets into insight and automation. On the design side, AI algorithms crunch imagery, geospatial data and historical records to suggest optimal routes, structural forms or material mixes. For example, AI‑powered simulation tools can test countless “what‑if” scenarios, traffic flows, weather impacts or material fatigue, much faster than human calculations. Indeed, modern BIM platforms explicitly integrate AI and IoT, creating a “dynamic process” where machine learning informs every decision. While specific applications vary, the result is a leap in accuracy: engineers can catch design flaws earlier, forecast project outcomes more reliably, and continually refine plans as new data arrives.

Perhaps most visible on the construction site is AI’s impact on safety and efficiency. AI‑powered vision systems are becoming the 24/7 sentinels of modern worksites. High‑resolution cameras and machine learning algorithms continuously scan the job environment, instantly spotting hazards or compliance issues. For instance, one AI camera system can now detect if a worker is missing a hard hat or high‑vis vest and alert supervisors immediately. Early trials even show promising results: one automated PPE‑detection system reportedly “cut workplace accidents by up to 50%” by flagging gear violations in real time. In effect, AI systems are reactive supervisors that never blink.

Beyond PPE, AI identifies risks that human eyes might miss. Sophisticated image analytics can flag “unguarded edges, missing barriers or unstable scaffolds” automatically. Over time, these systems learn patterns, for example, correlating minor slips or speed violations with future mishaps. Every near‑miss or alert is logged to the cloud, turning each incident into data for safety improvements. As Leica Geosystems’ Neil Williams explains, these AI assistants “enhance safety in the present with instant alerts and shape future strategies through comprehensive reports.” Every alert becomes a lesson in accident prevention.

AI is also extending its reach to site equipment. Modern heavy machinery comes equipped with 360° cameras and edge‑AI processors to protect operators and crews. Leica’s new Xsight360 system, for example, uses intelligent vision to detect people or obstacles in a machine’s path and instantly trigger audible and visual warnings. This buys critical seconds for an operator to react, reducing collisions caused by human distraction. Just as importantly, the system logs “near‑miss” data to a central dashboard. Safety managers can then analyse trends, such as repeated speed violations or high‑risk work zones, and proactively redesign the site or training programs to eliminate the root causes.

VR (virtual reality) and AR (augmented reality) are further examples of AI‑enhanced training. Safety training that once relied on manuals and slideshows is being replaced by immersive simulations. With VR headsets, workers can virtually operate cranes, respond to a sudden load swing or even navigate a trench collapse, all without real‑world danger. Interactive training like this greatly improves skill retention, because it lets workers “learn from mistakes in a risk‑free setting”. As a result, AI and data analytics are not just smoothing out design; they are literally helping contractors get ahead of accidents and inefficiencies on every site.

Robotics and Automation

Robots and automated machinery are tackling repetitive, dangerous tasks on site, helping to solve labour shortages and boost productivity. In fact, the construction robotics market is booming, valued at just $168.2 million in 2022, it’s expected to nearly quadruple by 2032. Firms around the world face a “perfect storm” of challenges: rising material costs and a lack of skilled workers (67% of companies report shortages) are driving new tech adoption. Robots offer a clear payoff. They slash labour costs, improve precision and allow projects to stay on schedule. Since labour can account for up to 30% of a project’s expenses, the efficiency gains are major.

Key advantages of construction robots include:

- Addressing labour gaps: As one report shows, most firms (81%) are anxious about surging costs and worker scarcity. Autonomous machines bridge that gap, ensuring deadlines are met.

- Boosting safety: Robots take on hazardous tasks like working at heights or in unstable environments, reducing injury risk. Equipped with AI, they can also monitor their own operation for faults and even shut down before malfunctions cause harm.

- Reducing waste: Automation’s precision lowers material waste. For example, 3D concrete printers build structures layer by layer, using exactly the right amount of material each time, which shrinks carbon footprints.

These benefits are seen in action on sites today. Autonomous earthmoving equipment, such as self‑driving bulldozers and excavators, are being field‑tested on large projects. Companies like Caterpillar and Komatsu now offer heavy machinery that follows pre‑programmed routes, adjusts to terrain changes in real time and requires minimal human intervention. Demolition robots are another success story: remote‑controlled walkers (by firms like Brokk) safely tear down concrete and brick structures from a distance, eliminating the need to send workers into unstable wreckage. Even material handling is automated, with fleet operators experimenting with driverless haul trucks and drones that transport supplies or map progress.

On the innovation horizon, humanoid robots are beginning to appear on sites. While still emerging, prototype bots from companies like Boston Dynamics or robotics start-ups are starting to perform tasks like bricklaying or welding, hinting at a future where robots may shoulder routine labours while humans focus on oversight and problem solving. In short, automation is steadily becoming the second crew on every job, helping projects stay on budget and moving faster.

The Internet of Construction Things

Beneath the buzz of AI and robotics is the vital network of IoT sensors and connectivity that makes smart construction possible. Today’s worksite is bristling with technology: embedded road sensors, CCTV cameras, GPS trackers and environmental monitors all gather data around the clock. These devices form an “Internet of Construction Things” that lets managers see what’s happening on site in real time. For example, inductive loop sensors and radar detectors in road surfaces can count vehicles and measure speed; cameras watch for traffic or worker movement; weather stations report wind and moisture levels, all feeding into control systems. This networked mesh of data is communicated via 5G and other wireless links (often called V2X for vehicle‑to‑everything) so that information flows instantly between the field and the project team.

Connected vehicle technology is also part of the mix. Modern machinery and even delivery trucks are linked into the site’s IoT platform. Drivers’ tablets may receive alerts from the project’s digital twin: for example, signalling when a lane will soon need to close or rerouting a delivery around a congestion point. Overhead, drones roam the site autonomously, capturing high‑resolution aerial imagery and 3D scans. In fact, highway authorities now use drone surveys and LiDAR to replace some manual inspections. These reality‑capture tools feed detailed models back into the BIM and twin so that as‑built conditions are continuously updated. In short, sites have become smart grids of data, they monitor their own wear and performance and let planners know when and where to act.

Of course, all these devices need robust communication. Projects rely on a mix of wired fibre, cellular (4G/5G) and low‑power wide‑area networks (LPWAN) to link sensors and machinery. High‑bandwidth links, sometimes using private 5G networks, are especially important for live video feeds and high‑speed control of robots or autonomous equipment. In many cases, work zones use portable cell sites and edge‑computing hubs so that latency is minimized, a camera monitoring a crane’s lift, for instance, cannot wait seconds for a command.

The payoff of IoT connectivity is massive. Sensor networks help crews find issues before they turn into breakdowns. For example, smart roadways now “talk” by reporting their own wear and tear. Pavement strain gauges, embedded GPS tags in bridge joints, or moisture sensors in concrete can alert teams to anomalies that the human eye would miss. Asset managers can see all this data on real‑time dashboards, automatically triggering maintenance orders. In the longer term, connectivity also enables analytics and machine learning: the more data flows in, the smarter the system gets at predicting needs (see next section). In short, IoT is the nervous system of the smart jobsite, it senses, communicates and even learns.

Predictive Maintenance and Data Analytics

The ultimate goal of smart construction is not only to build faster, but to keep infrastructure working longer and with fewer disruptions. That is where data‑driven maintenance comes in. Traditional maintenance was almost entirely reactive: crews patched potholes after they appeared, repaved sections on a fixed schedule or relied on ad‑hoc inspections. That often meant crises were caught too late, tiny cracks could grow into big failures, causing expensive repairs or safety hazards.

Now, thanks to connected sensors and data analysis, many projects are moving to proactive upkeep. Today’s highways and buildings continuously monitor their health. Algorithms analyse strain gauges, traffic flow data and weather patterns to predict where failures will occur. International forums note that governments are actively shifting to “maintenance policies that provide better value for money,” using digital tools to stay ahead of problems. The result is a big shift: instead of waiting for disaster, agencies aim to catch issues in the incipient stage.

Consider a pavement monitoring system that counts the tiny strains of vehicles over time. If a particular section shows abnormal bending, the system flags it to engineers before potholes form. Sensors on a bridge might notice a bolt loosening, triggering a drone inspection and quick tightening rather than risking a crack. Data analytics also helps optimise maintenance budgets: by predicting needs, agencies can replace sections before catastrophic failure, avoiding emergency road closures and premium repair costs. Engineers can also compare similar sites: if one tunnel’s humidity sensors indicate corrosion early, crews can pre‑treat the next tunnel in line.

Key benefits of this data-driven approach include:

- Early problem detection: Continuous monitoring catches subtle signs of deterioration (a small crack or drainage issue) long before it grows into a big problem.

- Cost efficiency: Fixing minor defects (like sealing a crack) is far cheaper than rebuilding a collapsed section. Data helps planners target interventions where they’ll do the most good.

- Less downtime: Because repairs are scheduled based on need (not emergencies), major structures spend more time in use. Planned maintenance can be performed at off‑peak times, so motorists and building occupants face fewer surprises.

- Improved safety: By solving hazards in advance, proactive upkeep prevents accidents. Clearing debris, reinforcing barriers or resurfacing rough spots before they degrade protects both workers and the public.

- Extended asset life: Regular, timely servicing (from re‑painting road markings to replacing worn bearings) simply keeps infrastructure in better shape longer, just as servicing a car extends its mileage.

These improvements translate to real‑world savings. For example, one highway authority reports that data‑driven interventions reduced its emergency repairs by over 30%, cutting maintenance costs while keeping roads more reliable. In cities, this means fewer surprise closures and better traffic flow; for remote highways, it can avoid costly helicopter inspections by using roadside sensors instead.

More broadly, predictive maintenance supports sustainability: well‑maintained assets need less energy to operate (smoother roads reduce vehicle emissions) and use fewer new materials over time.

Cybersecurity in Construction

As construction becomes smarter and more connected, cybersecurity moves from a back‑office concern to mission‑critical strategy. Every new sensor, robot or digital twin added to a project also adds to the digital attack surface. If these systems are not properly secured, the data they collect or the controls they provide can be hijacked or corrupted. In fact, public infrastructure is already under attack. Security analyses reveal that many traffic signals, cameras and roadside signs were never designed with security in mind. Early tests showed how “traffic light controllers were communicating over an unencrypted radio link… using default factory-set usernames and passwords.” Researchers easily took control of 100 intersections in one U.S. city, demonstrating how weakly secured IoT devices can be “terrifyingly easy” to hack.

Today, transportation agencies say they regularly find smart‑road IoT devices exposed on the public internet or still using default passwords. The U.S. Department of Homeland Security warns that as we pack more networked tech into highways and buildings, systems become “open to a vastly larger number of potential cyber threats.” Even mundane devices have been targeted: pranksters have hacked roadside message boards (using default credentials or physical access) to broadcast jokes or false alerts. While silly in itself, such tampering shows how poorly secured units can be hijacked, undermining trust and potentially distracting drivers.

More dangerous scenarios are possible. Imagine an attacker who spoofs weather sensors and feeds a false ice‑detection report into a road’s control system, causing automatic slowdown signs to activate for no reason. Or malware planted on a site’s network that quietly reroutes critical data from the digital twin, leading to flawed construction decisions. Researchers have modelled how an attacker jamming just 14% of traffic lights or hacking a small fraction of connected cars could gridlock a city, a cyber‑induced jam far worse than any power outage fail‑safe. In the worst case, coordinated attacks could flash red lights city‑wide, trap emergency vehicles, and create cascading chaos far beyond what any storm would cause.

Real incidents underline the point. In 2018, the Colorado Department of Transportation was hit by ransomware. Thanks to robust network design, the attackers encrypted office computers but “did not affect the critical systems used to manage road traffic and alerts.” Local IT teams isolated infected machines and restored data from backups, so signals and toll systems kept running. Yet the attack still caused days of disruption and massive clean-up costs. More recently, transport authorities in Europe faced waves of DDoS (denial‑of‑service) attacks that knocked out public travel websites and electronic toll payments. Those incidents show geopolitically‑motivated hackers are testing infrastructure as a target, and that even simple floods of traffic can cripple digital road networks.

“As construction sites evolve into data‑driven ecosystems, our digital attack surface is expanding dramatically,” notes Avery Dean, a cybersecurity consultant at BASALT Cyber. “Every sensor and digital twin is a potential entry point for attackers. We must bake security in from the ground up.” Dean stresses that modern construction data, whether design models in the cloud or IoT feeds from a worksite, must be protected. “Secure digital twins and end‑to‑end encryption are no longer optional extras,” he says. “Encrypted data exchange and rigorous network segmentation ensure that the model you’re building on hasn’t been silently compromised.”

Industry leaders are taking note. Procurement requirements now demand that highway electronics and site equipment meet specific cybersecurity standards. Networks are being segmented so that even if a camera or crane is breached, it can’t touch the project’s central control systems. Best practices include using strong passwords, regular firmware updates, and encrypted communications on all links (even low‑band IoT channels). For instance, highway management centres often mirror their operational networks and continually test incident drills, so they can respond to breaches quickly. As Dean puts it, “We must move from reactive security (patching after the fact) to a proactive stance: continuous monitoring, threat hunting, and secure‑by‑design devices.”

In short, cybersecurity underpins everything in smart construction. Without it, data-driven tools become liabilities. Every project team must now consider the question: if our digital twin were attacked, could we detect it? Can we trust the safety alarms or the AI analytics? The cost of ignoring these questions is too high. When done right, however, secure systems make “smart” construction robust: projects benefit from real-time insights while ensuring that their innovations don’t become digital Achilles’ heels.

A Smarter, Safer Future

Smart construction is no longer science fiction. By combining BIM, AI, robotics, IoT and secure data practices, the industry is fundamentally rewriting how projects are delivered. Builders can now predict problems, save costs, and safeguard crews like never before. Of course, technology alone isn’t enough, it must be paired with the right skills, standards and regulations. But one thing is clear: the companies and governments that seize this digital wave will set new benchmarks for productivity and sustainability.

More important, tech is making construction safer, greener and more efficient. The digital future of construction is bright, because it means fewer shocks for budgets, fewer accidents on site, and infrastructure that serves communities better. The roads, bridges and buildings of tomorrow will be born not just from concrete and steel, but from data and code. And as one UK infrastructure chief observed, we’re at the beginning of “a digital revolution in roads”, a revolution that promises smarter journeys and a more resilient built environment.