A Kinetics-Based Model Reshaping 3D Printing in Construction

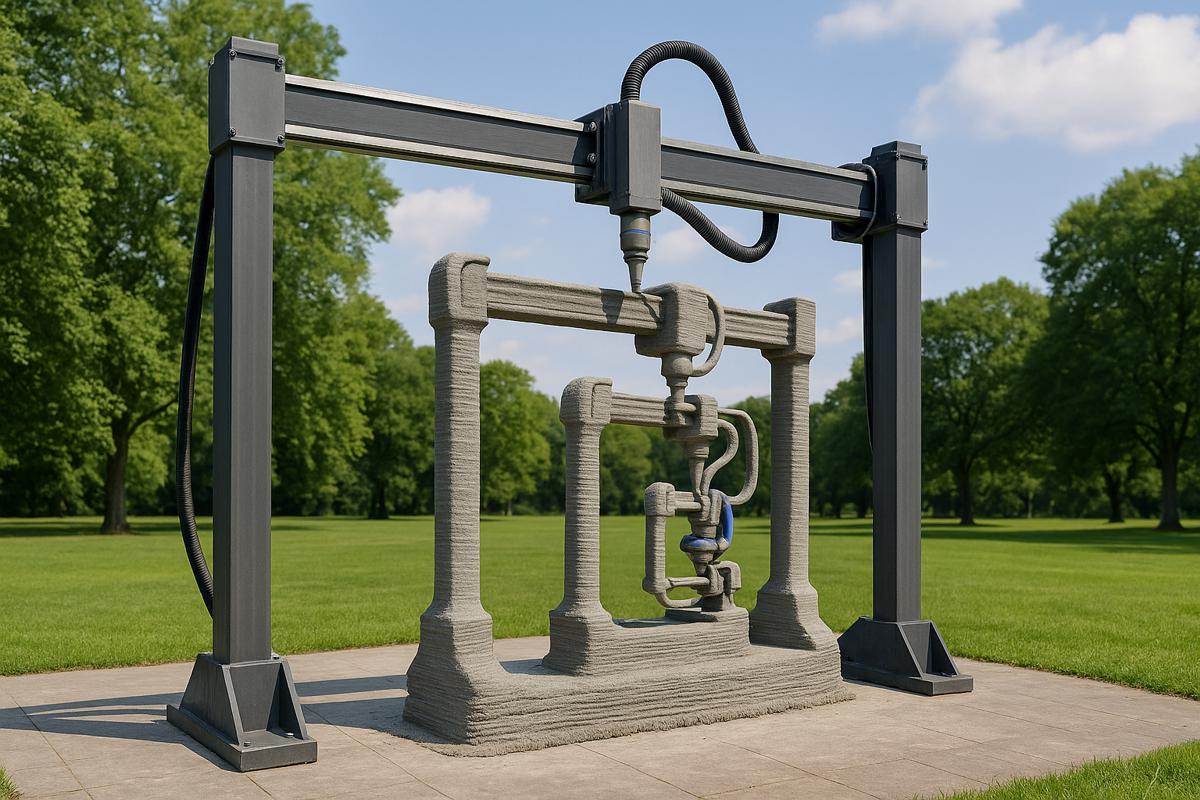

Three-dimensional concrete printing (3DCP) has quickly become one of the most promising innovations in modern construction. It offers the potential for faster, more sustainable, and highly precise building processes with minimal labour and waste. Yet, despite its rapid rise, the technology still faces a fundamental challenge: understanding and predicting how concrete behaves during printing.

At the heart of the problem lies the concept of thixotropy, the reversible transformation of concrete’s viscosity under stress. In simpler terms, when the concrete is extruded through a printer nozzle, it needs to flow smoothly, yet once deposited, it must quickly regain stiffness to hold its shape. This delicate balance is key to ensuring the buildability and structural integrity of printed layers. However, conventional models struggle to capture the full picture of how flocculation, deflocculation, and chemical hydration interact in this process.

Groundbreaking Research from India and Hong Kong

Recognising this challenge, a joint team from India’s CSIR-Structural Engineering Research Centre (SERC) and City University of Hong Kong has developed a new theoretical model that may redefine how engineers predict and control the behaviour of printable concrete. Their research, titled “Structural build-up model for three-dimensional concrete printing based on kinetics theory”, was published in the Frontiers of Structural and Civil Engineering Journal.

Authored by Prabhat Ranjan Prem, P. S. Ambily, Shankar Kumar, Greeshma Giridhar, and Dengwu Jiao, the study presents a structural kinetics-based model that provides a time-independent constitutive relationship for 3DCP materials, something long sought after in the industry.

A Kinetics Theory Approach to Concrete Behaviour

The model takes an in-depth look at how the internal structure of concrete evolves over time, particularly during resting, pumping, and deposition phases. Using a structural kinetics framework, the researchers incorporated three critical mechanisms:

- Flocculation: The process where cement particles clump together, forming an internal network.

- Deflocculation: The breakdown of these networks under shear stress during extrusion.

- Chemical Hydration: The irreversible reaction between water and cement that strengthens the material.

By integrating these factors, the model can accurately predict both static and dynamic yield stress, two vital parameters that determine how the concrete transitions between solid and liquid states. This enables engineers to simulate how the material behaves throughout the entire printing cycle.

Bridging the Gap Between Theory and Practice

Previous approaches to modelling 3D printable concrete often oversimplified the physical processes involved. Many failed to address how reversible structural changes interact with irreversible hydration effects, resulting in incomplete predictions. The new kinetics-based model closes this gap, offering a far more realistic representation of material behaviour.

The team’s experiments demonstrated that the model aligns closely with laboratory results, validating its predictive accuracy. It successfully mirrors the changes in yield stress over time and across different conditions, including variations in fibre dosage, shear rate, and rest duration. Such precision opens the door to fine-tuning mix proportions and printing parameters for specific applications, from architectural components to large-scale infrastructure elements.

Implications for the Construction Industry

The potential impact of this research extends well beyond academic circles. As 3D concrete printing gains traction worldwide, engineers and contractors are increasingly seeking ways to optimise performance, reduce costs, and enhance safety. This model provides a scientific foundation for doing exactly that.

“This model provides a reliable theoretical basis for optimising the mix proportion and printing parameters of three-dimensional printable concrete, and promotes the further development of this technology in engineering practice.”

With the ability to simulate real-world conditions, construction firms can minimise trial-and-error in mix design, streamline production workflows, and ensure consistent quality in printed structures. This represents a significant step toward making 3DCP a mainstream solution in both residential and industrial projects.

Beyond the Lab: Real-World Applications

One of the most exciting aspects of 3D concrete printing is its versatility. From affordable housing projects to futuristic architectural forms, the technology enables rapid prototyping and on-site construction that traditional methods simply cannot match. However, achieving consistent results requires deep insight into material science.

The kinetics model developed by the CSIR-SERC and City University team could be applied to various 3D printing systems, including those using ultra-high-performance concrete (UHPC) and fibre-reinforced composites. It can also help researchers develop printable mortars optimised for sustainability, using recycled aggregates, supplementary cementitious materials, or low-carbon binders.

Moreover, this model could inform the design of automated feedback systems in robotic printers. By continuously monitoring and adjusting material flow based on predicted yield stress behaviour, machines could adapt in real time to maintain layer stability and surface quality.

A Step Closer to Fully Digital Construction

The broader vision for 3D concrete printing lies within the digital construction ecosystem, where building information modelling (BIM), automation, and artificial intelligence work in harmony. Predictive models like this one bridge the gap between digital design and material reality, allowing seamless integration between software and hardware.

As the construction industry shifts towards smart factories and on-site automation, having accurate, adaptable models of material behaviour becomes essential. This research moves the sector closer to that reality, offering a scientific basis for more predictable, scalable, and sustainable 3D printing operations.

Building Smarter, Not Harder

The collaboration between India and Hong Kong highlights the global nature of construction innovation. Their kinetics-based model is a vital contribution to the evolving science of digital fabrication. As research continues, future iterations may incorporate data-driven enhancements, combining kinetics theory with machine learning to predict and control behaviour even more precisely.

The promise of 3D concrete printing is immense: shorter construction times, minimal waste, lower costs, and unprecedented design freedom. Yet, it’s models like this one that will transform the promise into practice, enabling engineers to print smarter, stronger, and more sustainable structures.