Herrenknecht celebrates Alpine Breakthrough

The Brenner Base Tunnel continues to carve its way through the rugged Alpine spine of Europe, quietly reshaping how the continent will move people and goods for generations. Eight tunnel boring machines manufactured by Herrenknecht have already excavated around 83.4 kilometres of tunnel between Austria and Italy, marking one of the most ambitious engineering feats on the continent.

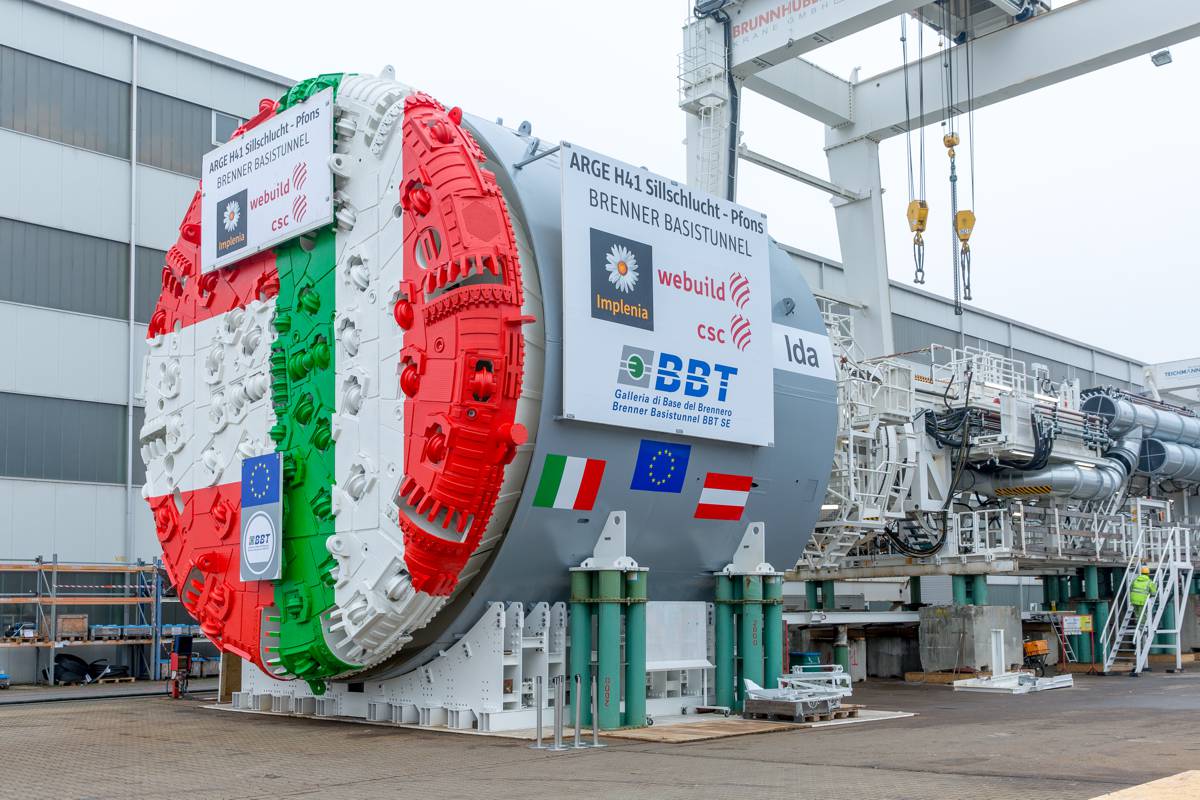

On 11 November 2025, deep within the H41 Sill Gorge‑Pfons construction section south of Innsbruck, the project team gathered to celebrate a major moment. Two Single Shield TBMs, affectionately named Lilia and Ida, finally broke through the final wall of rock, completing their long underground drives.

The ceremony underscored a year of extraordinary progress, bringing the Brenner Base Tunnel ever closer to becoming the world’s longest underground railway connection. With each breakthrough, the project not only advances Europe’s future high-performance rail network but also demonstrates the ingenuity of the teams steering these colossal machines through unforgiving geology.

Milestones Beneath the Alps

By late 2025, the Brenner Base Tunnel had logged several major achievements. TBMs Lilia and Ida, each weighing over 2,400 tonnes and stretching approximately 160 metres, completed their drives in the eastern and western main tubes of the H41 Sill Gorge‑Pfons lot. Their progress since May and June 2023 has been striking, with more than 8 kilometres excavated and lined with precision-engineered precast concrete segments.

Lilia became the sixth Herrenknecht TBM to finish its mission at Brenner, reaching its target in early October. Ida followed in August, advancing through equally challenging terrain. Two additional Double Shield TBMs, with diameters of 10.33 metres, continue to push southward in the H53 Pfonsâ€‑Brenner section. Once all machines complete their assignments, Herrenknecht’s combined contribution will total close to 90 kilometres of main and exploratory tunnels.

The project’s leaders highlighted this momentum during the event. BBT’s CEOs Umberto Lebruto and Martin Gradnitzer shared: “2025 was an extraordinary year for the Brenner Base Tunnel in terms of construction progress. Not only the two TBMs in this construction lot, Ida and Lilia, but also the TBM Flavia in the Mauls construction lot have successfully completed their tunnelling work.”

Power and Precision Driving the Project

Despite their gentle names, Lilia and Ida are formidable machines. Their 10.25 metre cutterheads deliver 4,550 kW of drive power, equivalent to around 6,050 hp. The torque produced—22.16 kNm—gives these TBMs the muscle required to grind through the toughest Alpine rock. Their design as Single Shield machines allows them to bore and install lining segments efficiently in variable geological formations.

From the outset, their drives demanded meticulous planning, robust logistics, and a high degree of coordination among the project partners Implenia, Webuild and CSC, operating jointly as ARGE H41 Silschlucht‑Pfons. The combined expertise of these teams ensured smooth operations despite challenging rock conditions, groundwater pressures, and tight schedules.

Dr. Ing. E.h. Martin Herrenknecht, founder and CEO of Herrenknecht AG, praised the collaborative achievements: “The long machine drives at the Brenner are a tough challenge. Thanks to the bravura with which our customers are leading the way here, we are jointly writing a top reference in the history books of tunnel construction.”

The sentiment was echoed by Bernhard Wienhold, who leads the responsible project management at Herrenknecht AG: “Every day, true specialists are at work—both on the part of our service teams and the construction companies. I am always impressed by the expertise and commitment I see on the machines in the tunnel.”

Engineering at an Unprecedented Scale

The Brenner Base Tunnel is one of the most complex underground construction programmes ever attempted in Europe. Designed as a flat, low‑gradient rail link between Innsbruck and Fortezza, it will span 64 kilometres, making it the longest railway tunnel in the world once complete. The H41 and H53 sections represent critical links that must integrate seamlessly with the broader tunnel system.

What sets Brenner apart is not only its length but also its geological diversity. TBMs encounter flysch, schists, gneiss, and highly fractured rock that can change over short distances. Maintaining progress demands constant adaptation, real‑time data, continuous maintenance, and a supply chain capable of feeding thousands of concrete segments into the tunnel.

Driving through the Alps has historically been a battle against steep gradients and limited capacity. Modern base tunnels like Brenner resolve these constraints by running nearly flat, dramatically improving energy efficiency for freight and passenger services. The engineering gains translate directly into operational, economic and environmental benefits.

Equipment, Expertise and a Holistic Support Package

Herrenknecht’s involvement extends far beyond supplying TBMs. The company also provides a full technical ecosystem required for complex tunnelling operations. This includes segment production systems designed by Herrenknecht Formwork, allowing each concrete ring to be manufactured with exacting precision.

Advanced navigation and ring sequencing systems from VMT GmbH ensure that alignment remains accurate to tight tolerances. Meanwhile, multi‑kilometre conveyor systems from H+E GmbH keep muck removal efficient, supporting uninterrupted progress. The integration of these systems allows construction teams to maintain safety, accuracy and productivity throughout each drive.

For a mega‑project stretching across borders and geological zones, consistent technical support is critical. Herrenknecht’s service engineers remain embedded with the construction teams, providing rapid troubleshooting, performance monitoring and specialist insights.

Strengthening Europe’s Cross‑Alpine Network

The Brenner Base Tunnel forms part of the Scandinavianâ’€€‑Mediterranean Corridor, one of the EU’s most important TEN‑T freight routes. Its aim is to remove bottlenecks and create a smoother, greener logistics chain from northern Europe to the Mediterranean.

Previous rail lines over the Alps struggled with steep gradients and limited capacity, impairing journey times and restricting freight volumes. The Gotthard Base Tunnel, inaugurated in 2016, set a new benchmark for long base‑level crossings, easing rail transport between Uri and Ticino in Switzerland. Excavated primarily using Gripper TBMs built by Herrenknecht in Schwanau, it stretches 57 kilometres.

Following Brenner, the next major Alpine tunnelling endeavour will be the Mont Cenis Base Tunnel between Lyon and Turin. TELT, the bi‑national project owner, has already ordered six Herrenknecht TBMs and extensive associated equipment to drive more than 70 kilometres of new infrastructure. Together, these mega‑projects represent a generational shift in European mobility.

Shaping the Future of European Transport

As Europe pushes toward more sustainable and efficient mobility corridors, the Brenner Base Tunnel stands as a defining piece of the puzzle. Each breakthrough confirms both the value of the engineering effort and the long‑term benefits it will bring to cross‑border connectivity.

The momentum achieved through 2025 reflects years of planning, investment and technical mastery. With more breakthroughs ahead and the final commissioning approaching, the Brenner project continues to set new standards in underground construction.

Once complete, the tunnel will not only relieve pressure on Alpine road networks but also anchor a next‑generation rail system designed for speed, reliability and environmental performance.