Advancing Metal 3D Printing Through Real-Time Microstructural Insight

Additive manufacturing has steadily shifted from a niche capability to a core technology driving modern production. Its ability to build complex metal components layer by layer offers unmatched design freedom and a route to more resilient, flexible and sustainable supply chains. Yet one stubborn hurdle has remained for engineers and manufacturers alike: ensuring that every printed part delivers the same quality, reliability and performance.

That challenge is now several steps closer to being solved. Researchers at the U.S. Department of Energy’s Argonne National Laboratory, Oak Ridge National Laboratory and collaborating universities have achieved a breakthrough in understanding how metal microstructures evolve during the 3D printing process. For the first time, scientists have been able to watch the internal structure of metals form in real time as each layer is deposited, melted and solidified.

This milestone was made possible by the Advanced Photon Source, a DOE Office of Science user facility operated by Argonne. Its powerful X-ray capabilities enabled researchers to capture the earliest moments of solidification with unprecedented clarity, revealing how dislocations originate and how they evolve in the final printed component.

Understanding the Complexities of Layer-by-Layer Manufacturing

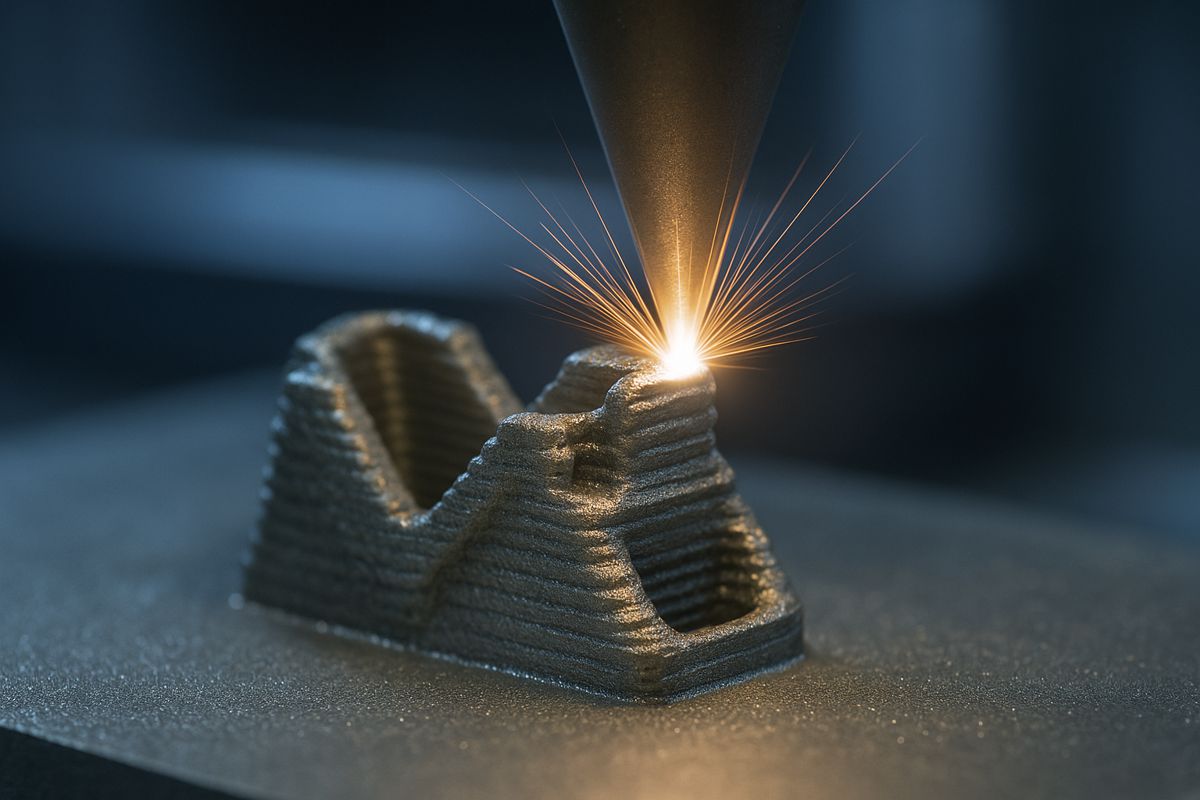

Additive manufacturing of metals has revolutionised production for industries such as aerospace, defence and healthcare. Instead of carving material away, manufacturers create components by depositing ultra-thin layers and fusing them with a laser or electron beam. The approach makes it possible to produce shapes that traditional machining could never achieve.

In the technique examined by the team, a high-intensity laser melts a thin metal wire. Once liquefied, the metal is deposited precisely onto the layer beneath, where it cools and solidifies almost instantly. This rapid sequence repeats until the full component takes shape. The challenge lies in controlling the microstructure that forms within each layer, because these microscopic features ultimately determine the strength, ductility and longevity of the finished part.

Traditionally, scientists have had to analyse the internal structure of 3D-printed parts only after the entire component was produced. That meant crucial details about how solidification progressed were missing, limiting the ability to optimise the printing process.

Capturing Metal Transformation in Real Time

The research team turned to the APS to bridge that knowledge gap. Using its high-brilliance X-ray beam, they conducted in situ monitoring of the printing of 316L stainless steel, one of the most widely used alloys in structural applications. The X-ray diffraction system enabled them to measure, with extraordinary precision, how dislocations formed and spread throughout the metal as it transitioned from liquid to solid.

The findings were striking. Dislocations appeared much earlier in the process than previously believed. Rather than forming as a result of thermal stresses that develop during cooling, they emerged right at the moment the liquid metal began to solidify. This early-stage formation was linked to a specific reaction in which two solid phases developed simultaneously from the molten pool, creating a remarkably high density of dislocations.

These insights challenge long-standing assumptions in the field. They reveal that microstructural behaviour is governed not only by post-solidification stresses but also by complex transformations that occur during the initial moments of crystallisation.

Engineering Better, Stronger and More Reliable Components

With this knowledge, engineers can begin tailoring printing parameters to guide dislocation formation in beneficial ways. Dislocations are not always detrimental. Under controlled conditions, they can enhance the strength and fatigue resistance of an alloy. The key is knowing when and how they form.

By precisely adjusting variables such as laser power, layer thickness or deposition speed, manufacturers could optimise microstructural features at a microscopic scale. This would lead to parts with predictable and high-performance characteristics, reducing variability and boosting trust in additive manufacturing for mission-critical applications.

This breakthrough also opens doors for the development of new alloys designed specifically for 3D printing. Small shifts in chemical composition, or the addition of elements such as aluminium, chromium or nickel, can alter how dislocations develop and how stress is distributed across the lattice structure. With a clearer understanding of these interactions, materials scientists can engineer alloys that are more stable, more resilient and better suited to the unique demands of additive manufacturing.

Unlocking Innovation Through Deeper Scientific Insight

Real-time X-ray observations offer a transformative view of additive manufacturing processes. By uncovering the intricacies of microstructure evolution, researchers have created a foundation for greater consistency and higher quality across the additive manufacturing ecosystem.

The implications reach beyond laboratory research. As industry seeks to close supply chain gaps, reduce waste and accelerate production timelines, metal 3D printing is emerging as a powerful tool for reshoring and modernising manufacturing capacity. These new insights can help accelerate that progress, giving engineers the detailed knowledge needed to build stronger, more reliable and more sustainable components.

With further development, this research could fuel a new generation of advanced alloys, smarter printing techniques and more dependable production systems. It marks a significant step toward unlocking the full potential of additive manufacturing.

Moving the Field Forward

The next phase of research will likely expand into more complex alloys and alternative printing techniques. Researchers are also exploring how artificial intelligence and machine learning can use real-time data to adapt printing parameters on the fly, making additive manufacturing more intelligent and self-correcting.

As scientific understanding deepens, the technology will become even more valuable to sectors that rely on precision-engineered metals. From hypersonic flight systems to medical implants and clean energy infrastructure, the ability to fine-tune microstructures could reshape design possibilities.

Additive manufacturing is no longer simply about building parts layer by layer. It is becoming a scientific discipline rooted in metallurgy, physics and data-driven engineering. With breakthroughs like this one, the industry is edging closer to producing metal components that consistently meet the highest standards of safety and performance.