Scalable Ceramic Additive Manufacturing for Extreme Environments

Ceramic engineering has inched forward for decades, yet one stubborn hurdle has repeatedly held back its wider industrial adoption: producing large, leak‑tight components at scale. That barrier has now been decisively lowered through a technical collaboration between the U.S. Department of Energy’s Oak Ridge National Laboratory and chemical technology specialist Dimensional Energy.

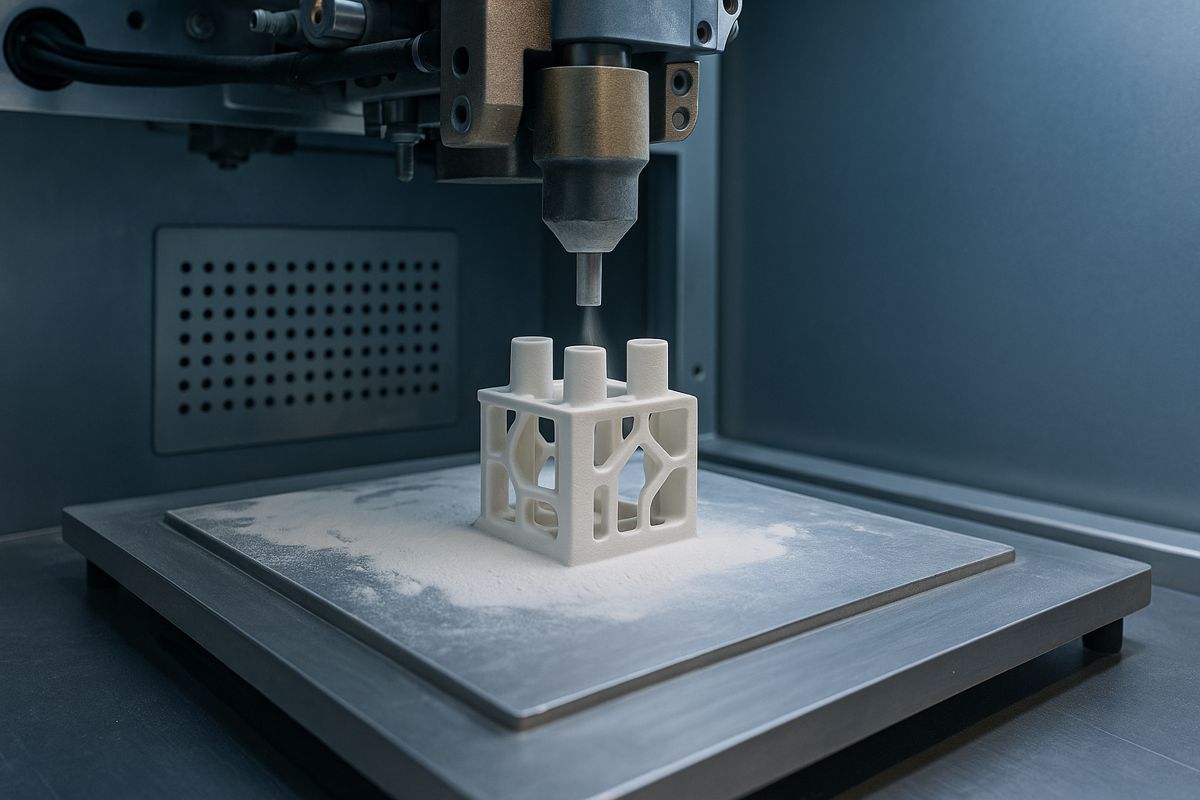

By merging binder jet additive manufacturing with a refined post‑processing method, the team has demonstrated a viable pathway to build intricate ceramic assemblies capable of meeting the demanding requirements of chemical reactors, aerospace systems and other extreme‑environment applications.

Advancing Ceramics for Extreme Environments

Ceramic components are prized in sectors where high temperatures, aggressive chemicals and sustained mechanical loads are routine. Energy developers, chemical processors and aerospace engineers all rely on ceramics for their durability and stability. Their Achilles’ heel has traditionally been fabrication. Complex shapes are labour‑intensive to produce and assembling large structures without leaks has often proved unworkable.

Standard ceramic 3D printing has added welcome flexibility, yet limitations in build size, structural integrity and reliable sealing remain. Industrial reactors, for example, require monolithic or perfectly sealed assemblies to maintain gas‑tight performance. Without dependable joints, even the most advanced ceramic parts fall short of operational requirements.

ORNL researcher Trevor Aguirre underscored the challenge and opportunity: “Ceramic 3D printing allows fabrication of intricate and high-performance components that are difficult to achieve with traditional manufacturing methods”. He added that the breakthrough now offers a validated framework to create next‑generation reactor components.

Integrating Binder Jet Additive Manufacturing

The Oak Ridge-Dimensional Energy collaboration focused on enhancing binder jet additive manufacturing, or BJAM. In BJAM, layers of ceramic powder are selectively fused with a binder, building a component layer by layer. The method is fast, flexible and comparatively affordable, lending itself well to prototyping and production.

However, BJAM alone can struggle with producing large, monolithic pieces due to printer size limits and the risk of defects during sintering. To overcome this, the research team developed a robust joining technique that enables smaller printed ceramic segments to be bonded into larger, leak‑tight assemblies without compromising mechanical or chemical performance.

This approach is especially significant for applications such as:

- Pharmaceutical and chemical reactors requiring large, sealed internal channels.

- High‑temperature heat exchangers.

- Aerospace components exposed to thermal and structural extremes.

- Emerging energy systems, including solar‑to‑fuel reactors.

The capability to join pieces without sacrificing gas‑tightness marks a notable improvement over conventional ceramic manufacturing and earlier additive methods.

Demonstrating Gas‑Tight Performance

ORNL and Dimensional Energy conducted a detailed case study to confirm the reliability of the new method. The team evaluated multiple design architectures and fabrication sequences to establish the optimal geometry and surface conditions for achieving leak‑tight joints.

The research was bolstered by advanced post‑processing techniques designed to improve bonding at the microstructural level. These refinements addressed porosity, surface roughness and chemical compatibility between printed segments. The resulting components demonstrated strong seals, mechanical robustness and reliable performance under reactor‑like conditions.

Dimensional Energy Chief Science Officer Bradley Brennan emphasised the significance: “Dimensional Energy believes that ceramics have the potential to fill niche applications as components of a chemical refinery, with many properties vastly superior to metal alloys”. He acknowledged, however, that manufacturing complex ceramic parts and sealing them has been extremely difficult. Brennan credited Dr Bhargavi Mummareddy, calling her an expert who not only met but exceeded the project’s goals.

Industrial Implications and Wider Applications

The breakthrough could unlock a new generation of industrial ceramic technology. The ability to manufacture complex, large‑format ceramic structures at lower cost expands their relevance across several demanding sectors. Industries seeking energy‑efficient, corrosion‑resistant and high‑temperature components stand to benefit.

In chemical and pharmaceutical production, leak‑tight ceramic reactors can withstand harsh solvents and extreme temperatures while maintaining product purity. In aerospace, lightweight ceramic structures are increasingly used in propulsion systems, thermal protection layers and advanced sensors.

The affordability of BJAM, especially compared with traditional ceramic fabrication — strengthens the business case. Reduced material waste, lower energy requirements during manufacturing and the capacity to print geometries that conventional methods struggle with all improve cost‑to‑performance ratios.

Recognition and Research Momentum

The work has attracted significant industry recognition. The collaborative team received SME’s 2025 Dick Aubin Distinguished Paper Award, a leading honour for contributions to additive manufacturing. Related work has also been published in Ceramics International, marking the research as one of the most comprehensive efforts to date on scalable ceramic BJAM joining technologies.

The scientists and engineers contributing to the project include Trevor Aguirre, Dylan Richardson, Corson Cramer, Amy Elliott and Kashif Nawaz from ORNL, collaborating with Bhargavi Mummareddy, Franklin Milton and Bradley Brennan from Dimensional Energy.

The research was funded by the DOE’s Advanced Research Projects Agency–Energy and the Office of Energy Efficiency and Renewable Energy. It was carried out at the Manufacturing Demonstration Facility, a national hub dedicated to advanced materials development and industrial transformation.

Building Momentum for Next‑Generation Ceramic Manufacturing

The leak‑tight ceramic joint produced through BJAM represents a pivotal step toward scalable ceramic reactors and high‑performance assemblies. With industrial sectors racing to improve efficiency, durability and sustainability, advanced ceramics are well positioned to play an increasingly strategic role.

This research demonstrates that manufacturing challenges, long seen as obstacles, are now being addressed with scientific rigour and practical engineering solutions.