Floating Construction and the Future of UK Offshore Wind

Floating offshore wind is moving from ambition to delivery, and the question facing the UK is no longer whether the sector will grow, but how quickly the supply chain can scale to meet it. A £1 million award to Sperra Seaworks Limited, supported by Bardex Energy UK Limited, through The Crown Estate’s Supply Chain Accelerator programme signals a growing focus on practical, nearshore solutions that could unlock capacity, reduce risk, and keep more value anchored in British ports.

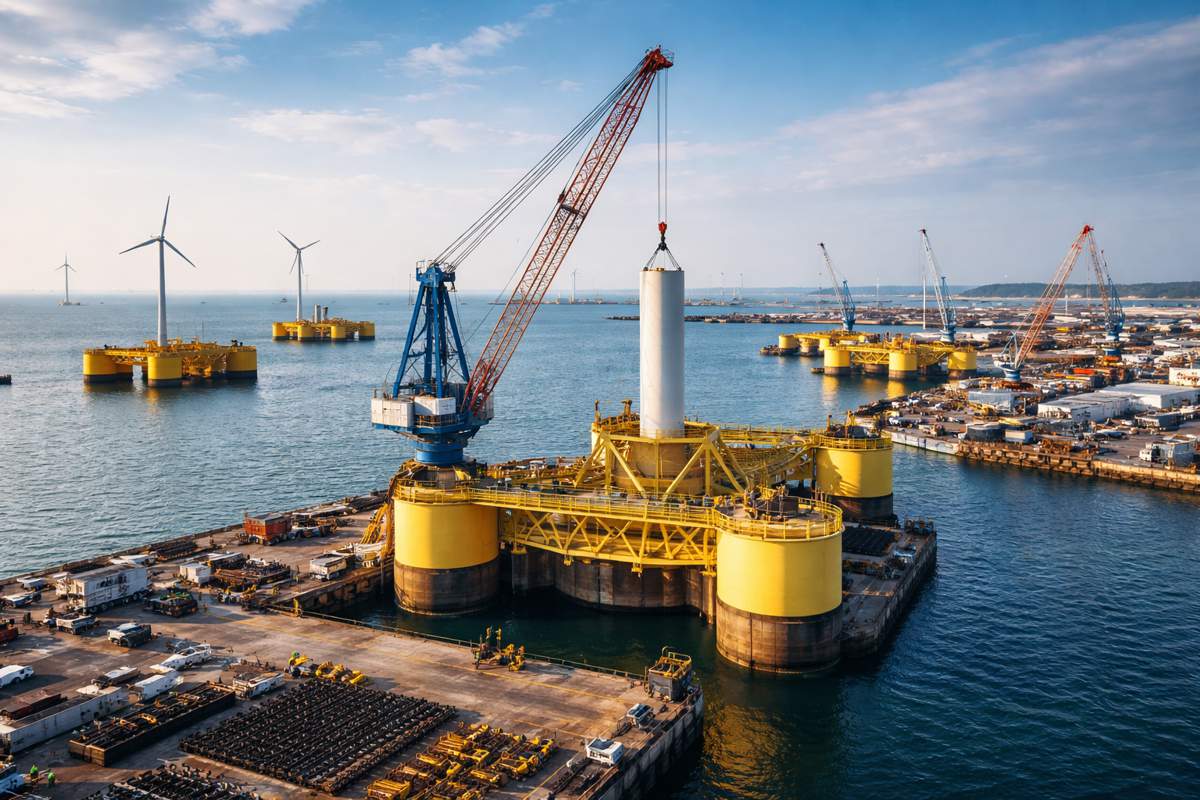

At the heart of the work sits the Floating Construction Station, a deployable offshore manufacturing and assembly concept designed to support floating wind foundations at scale. With additional industry match funding and links to earlier research supported by the National Offshore Wind R&D Consortium, the project arrives at a critical moment for the UK’s floating wind ambitions, particularly in the Celtic Sea.

Why Floating Wind Needs New Infrastructure Thinking

Floating offshore wind has long promised access to deeper waters and stronger, more consistent wind resources. Yet despite rapid progress in turbine design and mooring technology, construction logistics remain a stubborn bottleneck. Traditional port infrastructure was never designed to assemble, integrate, and launch floating foundations measured in tens of thousands of tonnes.

Across Europe, developers and policymakers are confronting the same reality. Large areas of quay space, deep water access, heavy lift capability, and rapid turnaround are essential, yet scarce. Without new approaches, competition for suitable ports risks slowing deployment timelines and pushing costs upward.

The Floating Construction Station concept tackles this challenge directly by shifting a significant portion of fabrication, integration, and launch activity onto a floating platform. In doing so, it opens the door to nearshore manufacturing models that can be deployed where they are needed, rather than forcing projects to conform to fixed port limitations.

A Strategic Boost From The Crown Estate’s Supply Chain Accelerator

The funding award comes through The Crown Estate’s Supply Chain Accelerator programme, an initiative designed to strengthen domestic capability for large scale offshore wind. Rather than supporting isolated technologies, the programme targets solutions that address systemic gaps across the construction and delivery chain.

For floating wind, that gap increasingly sits between foundation fabrication and offshore installation. By supporting early engineering and feasibility work on the Floating Construction Station, the programme is backing an approach that could be replicated across multiple UK ports, adapting to local conditions while maintaining standardised processes.

Jason Cotrell of Sperra Seaworks Limited underlined the importance of this stage of development: “Floating wind in the Celtic Sea represents one of the UK’s most significant industrial opportunities. Support from The Crown Estate’s SCA programme and NOWRDC allows us to complete the engineering and feasibility studies needed to evaluate this concept and bring it to an investment ready stage.”

Engineering The Floating Construction Station

The Floating Construction Station is envisioned as a multi purpose floating platform capable of supporting manufacturing, assembly, launch, and retrieval of floating wind foundations. Unlike fixed infrastructure, it can be deployed at different ports and adjusted to suit local bathymetry, access constraints, and regulatory environments.

A central feature of the concept is its integration with Bardex’s OmniLift chain jack shiplift system. OmniLift is not an experimental technology. It is already operational in heavy marine and industrial settings worldwide, where precise load control and reliability under extreme conditions are non negotiable.

Ian Finch, Director of Business Development EMEA at Bardex Energy UK Limited, highlighted the practical nature of the approach: “The Floating Construction Station, integrated with our OmniLift system, provides a practical pathway to simplify how floating wind foundations are handled and deployed. Our technology is proven today in demanding environments, and we are excited to support its evaluation for the UK’s floating wind sector.”

By combining a floating platform with established heavy lift and transfer systems, the project aims to reduce technical risk while accelerating readiness for commercial deployment.

Building On Previous Research And Collaboration

The work funded through the Supply Chain Accelerator does not stand alone. It builds on an ongoing Sperra project supported by the National Offshore Wind R&D Consortium, ensuring continuity between early research and applied engineering.

This layered approach reflects a broader shift in offshore wind innovation. Rather than pursuing isolated pilot projects, industry and government are increasingly focused on pipelines that move concepts from feasibility to deployment with minimal loss of momentum.

Through preliminary engineering studies, site assessments, and early consenting strategies, the Floating Construction Station project is intended to emerge from this phase with a clear pathway to construction of a first full scale unit in the UK.

Port Talbot And The Celtic Sea Opportunity

Although the Floating Construction Station is designed to be adaptable, early assessments have identified Port Talbot as a promising candidate location. The port’s deep water access, industrial waterfront, and proximity to the Celtic Sea place it firmly within the conversation around floating wind deployment.

Port Talbot’s involvement in the Celtic Freeport initiative and its assessment under the UK Government’s Floating Offshore Wind Manufacturing Investment Scheme further strengthen its strategic position. These programmes are aimed at ensuring ports can host large scale manufacturing while delivering economic regeneration and long term employment.

Andy Reay, Head of Offshore Wind at Associated British Ports, emphasised the importance of early evaluation: “Port Talbot has an important role to play in enabling floating wind in the Celtic Sea. We welcome early stage technical work that helps evaluate feasibility, regulatory pathways, and the potential contribution of new infrastructure concepts such as the Floating Construction Station.”

While Port Talbot is one option among several, the assessment process will help define where floating construction models offer the greatest return on investment and operational benefit.

Supporting The Celtic Sea Leasing Programme

The Crown Estate’s plans to lease up to 4.5 GW of floating offshore wind capacity in the Celtic Sea represent one of the most significant expansions of floating wind anywhere in Europe. Delivering that scale will require more than turbines and seabed leases. It demands integrated construction ecosystems.

Nearshore assembly enabled by Floating Construction Stations could play a vital role in meeting aggressive deployment timelines. By reducing tow out distances, minimising offshore installation complexity, and improving weather resilience during assembly, the model aligns closely with developer priorities.

Just as importantly, it supports domestic industrial participation. Keeping high value construction activity within UK waters strengthens local supply chains and helps ensure the economic benefits of floating wind remain close to home.

A Broader Industrial And Economic Case

Beyond individual projects, the Floating Construction Station concept speaks to a wider industrial strategy. Floating wind has the potential to reshape coastal economies, but only if infrastructure investment keeps pace with ambition.

Deployable nearshore construction platforms offer flexibility that fixed assets cannot. They can be redeployed between regions, support different foundation designs, and evolve alongside technology advances. That adaptability is particularly valuable in a sector still undergoing rapid innovation.

From an investor perspective, standardised floating construction assets could also reduce capital risk. Rather than bespoke port upgrades for each project, shared infrastructure models allow costs to be spread across multiple developments and users.

Positioning The UK For The Next Phase Of Floating Wind

Sperra Seaworks Limited, as the UK subsidiary of Sperra, brings a focus on marine infrastructure tailored to offshore renewable deployment. Bardex Energy UK Limited, drawing on the global experience of Bardex Corporation, contributes field proven heavy lift, mooring, and motion control systems already trusted in extreme marine environments.

Together, their collaboration reflects the type of cross sector partnership needed to move floating wind from demonstration to delivery. With support from The Crown Estate and alignment with national programmes such as FLOWMIS, the Floating Construction Station project is positioning itself as a practical response to one of the sector’s most pressing challenges.

As feasibility work progresses, the outcomes will be closely watched by developers, ports, and policymakers alike. If successful, Floating Construction Stations could become a cornerstone of how the UK builds floating wind at scale, not just in the Celtic Sea, but wherever deep water resources meet industrial ambition.