Humans and Machines Redefine Construction Careers

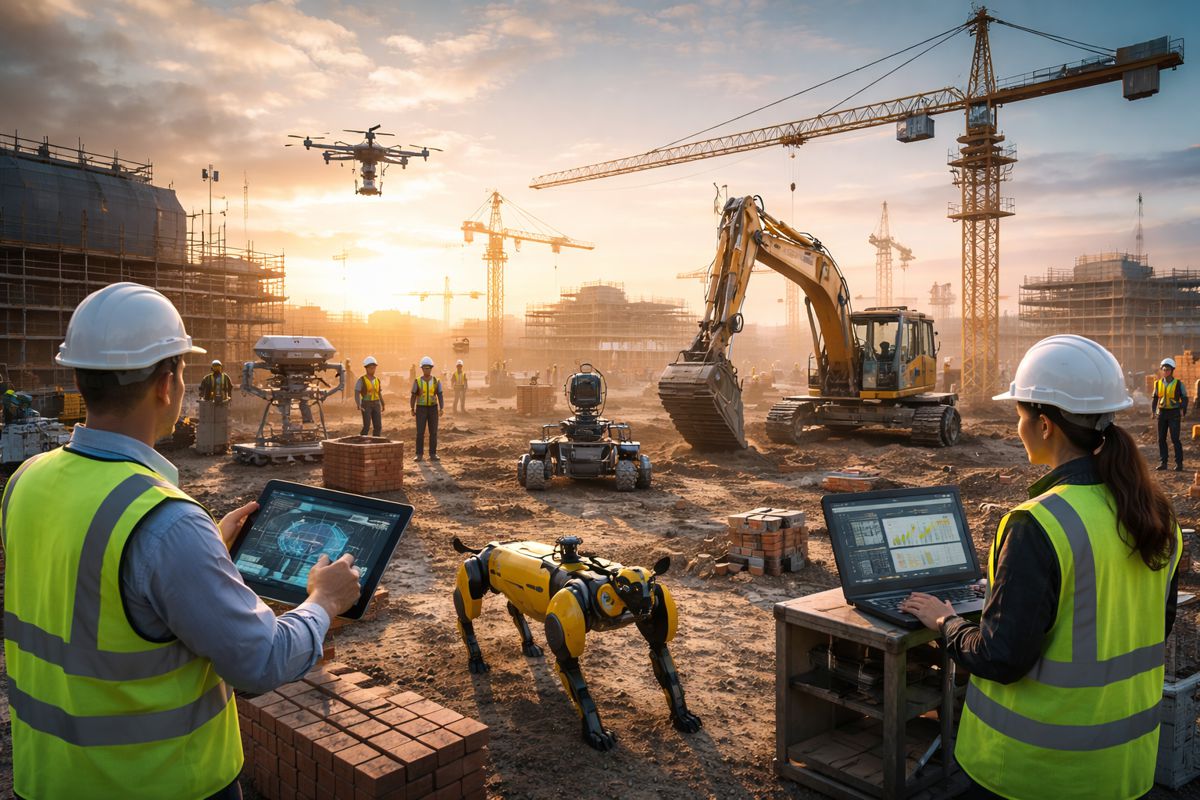

Around the world, construction sites are undergoing a quiet revolution. Machines are taking over the “dull, dirty, and dangerous” tasks, and human workers are stepping into new roles as technical supervisors, quality controllers, and data-driven decision-makers.

Far from rendering people obsolete, the rise of automation, robotics, and AI in construction is empowering the workforce, making jobs safer, workflows more efficient, and opening up entirely new career paths. As one industry innovator observed: “Construction is the most injury-prone industry across all job types. So there’s massive demand, insufficient labour supply, skyrocketing costs, and projects that simply don’t get done.”

In this context, humans and machines working together have become the key to building a smarter, more resilient construction workforce.

Automation Tackles Repetition and Risk

On modern jobsites, automation is increasingly handling repetitive, strenuous, or hazardous tasks that once took a heavy toll on human crews. From bricklaying to heavy lifting, robots and automated systems are being deployed to do the grunt work, and do it with superhuman consistency. A recent global study of construction robotics found promising results: robots could cut repetitive site work by anywhere from 25% to 90% and reduce time spent on dangerous tasks by 72% on average. In practice, this means machines can take on the tireless, injury-prone activities, such as lifting hundreds of bricks or breaking up concrete, while human workers avoid fatigue and life-altering injuries.

The safety benefits are impossible to ignore. Construction has long ranked among the most hazardous industries for workers, with a large share of injuries stemming from muscle strain, falls, and heavy manual labour. Automation offers a way to engineer out some of these risks. For example, demolition robots can be sent to tear down structures or break up slabs of concrete, sparing humans from exposure to falling debris and heavy vibrations.

Bricklaying robots (like the famous SAM100 in the US or Australia’s Hadrian X) methodically spread mortar and set bricks in place, alleviating the back-breaking repetition for masons while a human mason oversees quality and handles the tricky finishing details. Likewise, welding robots are being used in controlled environments, such as pre-fabrication shops or factories, to handle the precision welding of steel components. By letting machines do the tedious and risky parts of these jobs, contractors can significantly cut down on workplace injuries and long-term health issues among their crew (for instance, fewer chronic back problems or musculoskeletal disorders from repetitive motions).

It’s not just about safety, automation also boosts quality and speed. Robots don’t get tired or distracted, so tasks like drilling hundreds of holes or tying rebar can be done with laser-guided accuracy time and again. This level of precision reduces human error and the costly rework that often comes with it. In fact, the same study noted that accuracy improved by an average of 55% when robots were used, and projects saw far less rework.

Fewer mistakes mean construction elements fit as designed, inspections are passed on the first go, and overall project quality goes up. And because machines can work continuously (and often faster than humans for certain tasks), project schedules speed up markedly. Automated systems have delivered installations “as much as 50% faster” in some cases simply by cutting out downtime and maintaining optimal pace. In an industry where delays are common and costly, these efficiency gains can be game-changing.

Robots on the Jobsite

What do these construction robots and automated systems actually look like on site? Increasingly, they come in many forms, each specialized for a piece of the construction puzzle. Drones buzz overhead to survey large sites and inspect hard-to-reach areas, rover-like robots scurry across floors laying out markings, while mechanized arms and exoskeletons assist workers on the ground.

Today’s construction robots tend to be task-specific machines that excel at a narrow job. Here are a few prominent examples making waves in the industry:

Automated Surveyors and Drones

One of the most widely adopted robotic technologies in construction is the autonomous survey drone or layout robot. These devices map out sites in record time. Drones equipped with cameras and LiDAR can produce detailed 3D surveys and topographic maps far faster (and more safely) than a person with a tripod.

Ground-based bots like layout robots crawl across future floors, printing precise layouts for walls and utilities directly onto the slab. Civ Robotics’ CivDot, for instance, can mark thousands of points for solar farm installations, freeing survey crews from days of tedious stakeout work. Instead of carrying heavy equipment under the sun, surveyors now program the robot and oversee its progress. This not only speeds up the job but also eliminates human errors in measurements. It’s telling that drones and automated layout tools have seen a 239% surge in use on construction sites within a single year, making construction the leading sector for commercial drone deployment.

Survey teams, rather than fearing job loss, are evolving into drone pilots and data analysts, interpreting the rich aerial data to guide project decisions.

Robotic Paving and Earthmoving

Heavy civil works are also getting a tech upgrade. In road building, automated paving machines and rollers can be guided by GPS and onboard sensors to lay asphalt with perfect consistency. Some advanced pavers and graders use AI to adjust in real-time, achieving a level finish that reduces material waste.

Meanwhile, start-ups in the Middle East and beyond are debuting block-laying robots that build pavement or block walls faster and with less manual labour. These machines precisely place bricks or pavers in pre-programmed patterns, a job that normally takes a team of laborers bending and lifting all day. By taking over repetitive motions, the robots help avoid the typical injuries and fatigue, one reason contractors “avoid overexertion when laying bricks” as a safety tip.

Human workers still handle site preparation and guiding the robot, but their work is lighter and more focused on supervision.

Robotic Welding and Prefabrication

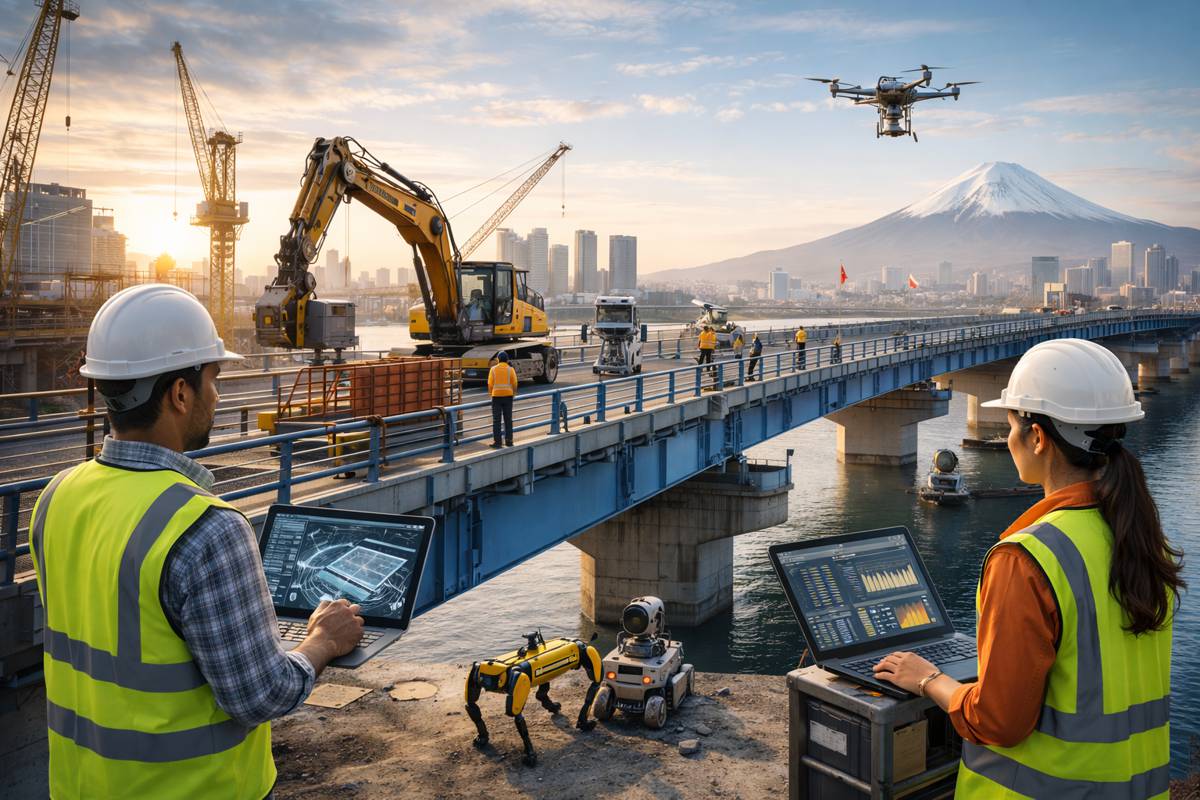

In high-rise construction and industrial projects, welding is a critical skill often in short supply, and poorly executed welds can be dangerous. Robotic welding arms are increasingly used in fabrication shops to weld steel beams, columns, and pipe sections automatically. For example, a bridge builder might use a robotic arm to weld rebar cages or steel girders, ensuring uniform weld quality on every joint.

These systems excel in controlled factory-like environments as part of the growing trend of off-site prefabrication. By the time components arrive on site, much of the labour (and risk) has been handled by machines under expert supervision. This off-site automation is making projects not only faster but also safer, since fewer workers need to perform hot works or heavy assembly at dangerous heights or in harsh weather.

Lifting Bots and Exoskeletons

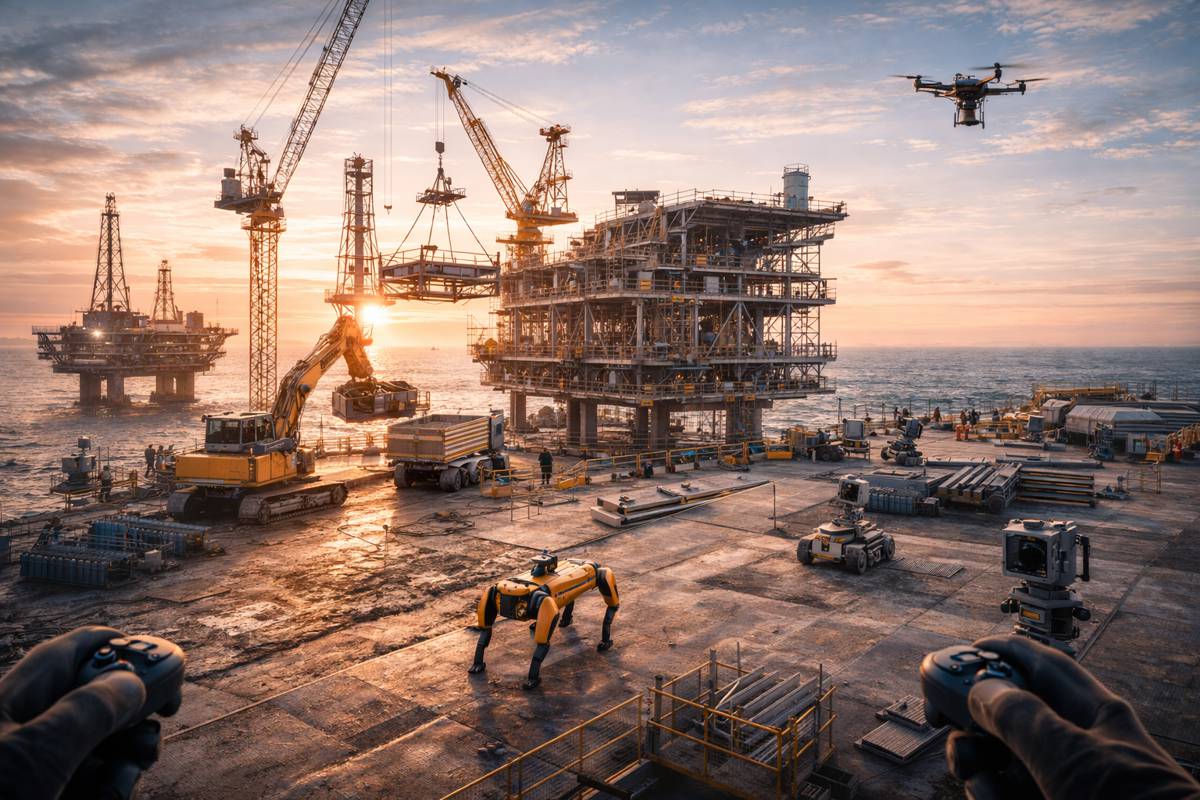

Even the age-old act of lifting and moving materials is being augmented by robotics. Automated guided vehicles (AGVs) and robotic forklifts can ferry heavy loads across large sites or warehouses without a driver, following digital pathways and sensors to avoid collisions. On-site, some firms use small autonomous or remote-controlled crawler robots to carry tools or haul debris out of confined spaces where it might be risky for humans. Additionally, wearable robotics like exoskeleton suits are empowering individual workers.

These mechanical assist devices strap onto a worker’s body and give extra strength or support, allowing, for instance, a technician to hold a heavy power tool overhead for longer or a labourer to lift panels with less strain. In effect, exoskeletons turn a single worker into something of a human-machine hybrid, significantly reducing fatigue and injury while boosting productivity (imagine one person installing what used to require two or three pairs of hands).

Inspection Robots

Robots are also crawling and climbing into places humans shouldn’t. Robotic camera crawlers inspect sewers, pipelines, and inside ductwork for defects. Boston Dynamics’ “Spot” robot dog, famously piloted on projects from Japan to the US, trots around construction sites carrying cameras and laser scanners to capture progress data and sniff out hazards. And drones equipped with thermal cameras fly up to inspect high mast light poles, wind turbines, or the top of tower cranes, tasks that would be perilous or impossible for a human inspector.

By using robots to collect this critical information, engineers can identify structural issues, water leaks, or safety concerns early, without endangering a person. These inspection bots are like tireless sentinels, checking every nook and cranny with a level of detail and consistency that humans would struggle to maintain.

What’s common across all these applications is that robots are taking on specific, labour-intensive tasks rather than entire jobs. The skilled human worker remains very much in the loop, setting up the machines, programming their work, monitoring their performance, and handling exceptions or fine details. This collaboration allows projects to benefit from robotic efficiency and precision while still relying on human judgement and experience where it counts.

As one Texas A&M construction research report put it: “Robots will not replace human workers in construction. Instead, they will automate tedious, repetitive, or risky tasks, giving human workers the ability to take on advanced construction positions.” In other words, the goal is augmentation, not replacement. By design, these technologies are tools to support the workforce, not a wholesale substitute for people on site.

AI “Co-Pilots” for Heavy Equipment Operators

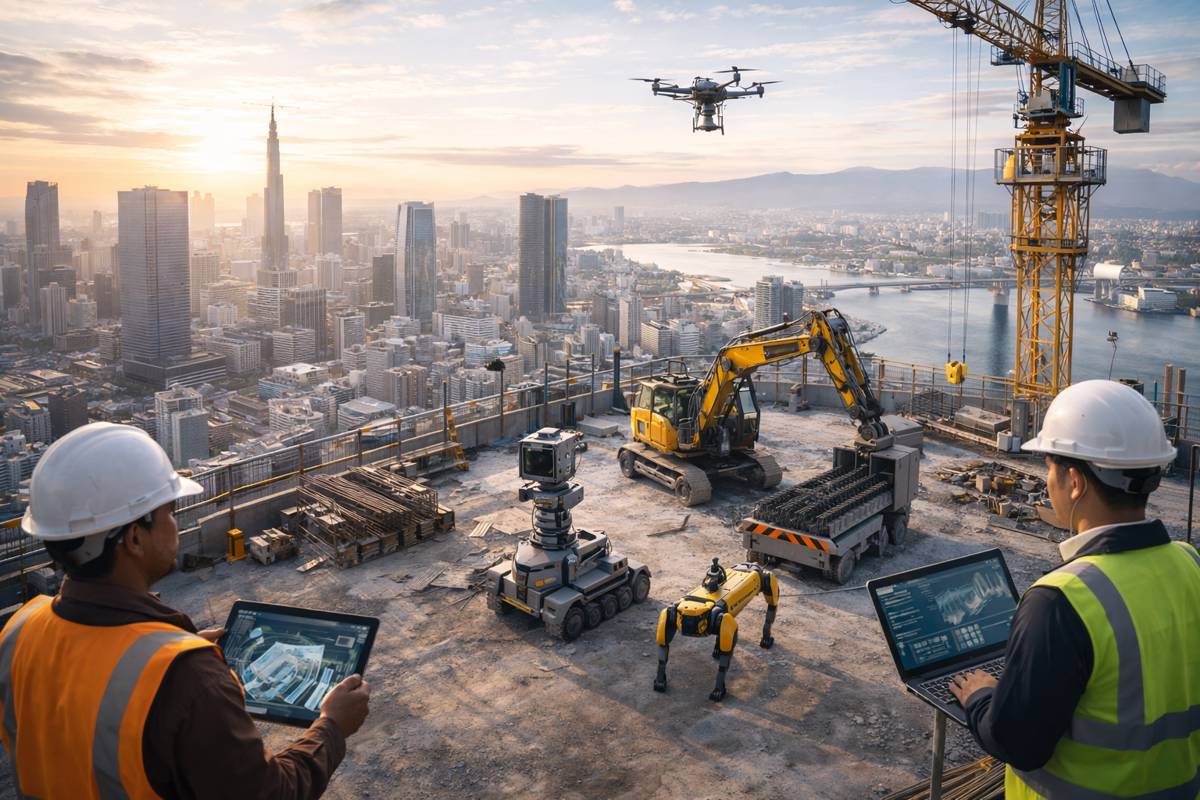

Beyond standalone robots, the industry is also embracing artificial intelligence as a co-pilot for heavy machinery. Think of the modern construction vehicle, bulldozer, excavator, crane, increasingly outfitted with smart sensors, onboard computers, and connectivity. AI-driven systems can assist the human operator in myriad ways: from precision guidance and safety overrides to partial automation of repetitive motions. The result is that even when a person is in the cab, they are often sharing control with intelligent software that helps them work faster and safer.

One example is the advent of smart excavators and bulldozers with GPS and AI guidance. Companies like Caterpillar, Komatsu, and emerging tech firms have developed grade control systems that use satellite positioning and digital design models to automatically adjust the machine’s blade or bucket. An operator might roughly position the dozer, but the AI will fine-tune the blade height to exactly meet the desired grade, ensuring the roadbed or foundation is level to spec. This turns the operator’s role into more of a supervisor, the machine handles the minutiae of the task while the human makes the high-level decisions.

In practice, a single operator can now manage multiple machines in a coordinated dance. In some pilot projects, one operator stationed at a laptop has remotely overseen a fleet of autonomous or semi-autonomous earthmoving machines digging and grading in tandem. The operator plans the work and monitors progress, but each bulldozer or excavator uses AI to carry out the plan and avoid obstacles. This setup tackles labour shortages by multiplying the impact of each operator’s skills, a glimpse of a future where a “equipment conductor” might replace several individual drivers.

AI co-pilots also shine in improving jobsite safety and equipment care. Construction machines are powerful but can be dangerous if something goes wrong. Modern equipment is being fitted with AI-powered camera systems that act as an extra set of eyes and reflexes. For instance, automatic braking or collision avoidance systems can detect a worker who wanders too close to a backing loader and stop the vehicle in time. Some cranes now come with AI stability monitors that warn or intervene if a lift is about to exceed safe parameters. These intelligent assistants help even seasoned operators avoid mistakes that could lead to accidents.

Another emerging application is wearable AI for operators, like smart hardhats or visors that display augmented reality (AR) data. Imagine an excavator operator seeing an overlay of underground utilities in their field of view, or a crane operator getting real-time wind speed and load angle alerts through a heads-up display. AI parses sensor data and feeds useful insights to the human at the controls, almost like a digital foreman whispering advice in their ear. This human-machine teamwork means tricky operations can be executed with greater confidence. As one report on AI in construction noted: “site managers still make the calls, but with AI as a co-pilot.” Even at the planning level, AI-driven software analyses project schedules, budgets, and models to suggest optimal actions, but leaves the final judgement to experienced managers.

Perhaps the most striking example of the co-pilot concept is in semi-autonomous driving and heavy haulage, especially in controlled environments like mines or large earthworks. In Australia and North America, autonomous haul trucks and drill rigs have been operating for years under human supervision from remote operation centres. Construction is now adapting these ideas: for instance, retrofitting excavators with an “autonomy kit” (pioneered by start-ups like Built Robotics) allows them to dig trenches automatically. On a pipeline job, a human might map out the trench path and then let the excavator’s AI dig to the correct depth and slope, intervening only if there’s an unexpected situation. An overseeing operator can handle multiple such excavators at once. Early trials of these systems have shown that they augment operators rather than replacing them, the machines handle the repetitive digging, but the human expert is still crucial for setup, problem-solving, and multi-tasking oversight.

The introduction of AI co-pilots is gradually changing the skill set required of equipment operators. Digital proficiency is becoming as important as muscle memory. Tomorrow’s heavy machine operator might need to be part driver, part IT technician, comfortable with setting up software, interpreting analytics on a tablet, and collaborating with an automated system. Those who embrace these tools are already seeing the benefit: they can achieve more in less time, and with less physical strain, than was possible a decade ago. Meanwhile, the overall risk of incidents goes down, because the AI is constantly monitoring for hazards or deviations that a human might miss after a long shift. It’s a powerful synergy, the seasoned judgement of a human paired with the tireless precision of a computer, making construction operations smarter and safer in real time.

From Manual Labour to Data-Driven Decision Making

As automation and AI handle more of the physical heavy lifting, the role of the human in construction is shifting towards oversight, quality control, and data-driven management. In essence, the nature of construction work is moving “from boots to brains”, leveraging human intelligence in new ways now that machines can handle some of the muscle. Rather than swinging hammers or driving loaders all day, many workers find themselves checking robot-laid work for accuracy, interpreting data streams, and making judgement calls that only experience can guide.

On the front lines, a concrete example is the mason working alongside a bricklaying robot. Where once a mason might have spent a day physically laying hundreds of bricks (and ending the day exhausted), now the robot lays the straight sections of wall. The mason’s day is spent ensuring the robot is loaded with mortar and bricks, then focusing on the intricate portions, like corners, edges, or aesthetic details, that the robot isn’t suited for. They might also be simultaneously planning the next day’s work, coordinating with other trades, or even flying a drone to survey how the new wall integrates with the rest of the structure.

In effect, the mason’s responsibility shifts upward: less manual repetition, more high-level supervision and craftsmanship where needed. Many trades are seeing similar transitions. Rebar installers could soon oversee machines tying steel bars together, intervening only for the trickiest sections. Asphalt paving crews might monitor automated pavers, with workers concentrating on ensuring the mix quality and smooth joints rather than raking asphalt all day.

Quality control is one area where human expertise will always be critical, and it’s being enhanced by digital tools. With drones scanning sites daily and sensors embedded in concrete, a massive amount of data is available about a project’s progress and quality. Human professionals, site managers, surveyors, quality inspectors, are increasingly acting as data analysts and decision-makers who interpret this flood of information. For example, after a drone flyover produces a 3D model of a jobsite, an engineer will compare it to the digital plans, often with software highlighting discrepancies. If a slight deviation in a steel frame is detected by an AI vision system, a human inspector still needs to determine if it’s within tolerance or if it needs correction.

The job is less about manually measuring with a tape and more about understanding what the digital twin is telling you and deciding the right course of action. In this way, data-driven decision making becomes a core skill. Construction professionals are becoming proficient in dashboards and analytics, whether it’s a safety officer reviewing AI-generated safety alerts, or a project manager getting automated schedule risk predictions from their management software.

Site management itself is evolving. Foremen and site supervisors now have tablets loaded with real-time updates on everything from equipment fuel levels to worker attendance and weather forecasts. AI-powered project management platforms can flag when a critical path item is slipping or when two subcontractors’ schedules are about to clash, so the manager can proactively resolve it.

The foreman’s morning routine might include reviewing an AI-curated report that says, for instance: “Section B concrete pour is at risk of delay due to forecast rain; recommend rescheduling to Friday.” The manager then uses their experience to adjust tasks accordingly, coordinating with teams via digital communication tools. This blend of human foresight and computer insight leads to more informed decisions. As one construction executive described, it’s like having a virtual assistant keeping an eye on the myriad moving parts of a project, allowing human managers to focus on leadership and critical problem-solving.

Crucially, this shift towards oversight and data doesn’t eliminate the need for on-site presence or practical know-how. Construction is still a very physical endeavour, materials, weather, and human coordination are involved, and things rarely go exactly as planned. That’s why human adaptability and creativity remain irreplaceable. A robot or AI might flag an issue, but deciding how to fix it (perhaps coming up with a clever on-site workaround) is often up to the seasoned project team.

The difference today is that the team is armed with far better information and tools to execute those decisions. In short, the human role is becoming less about doing and more about thinking, ensuring, and leading. Workers are, in a sense, moving from the front lines to the command centre of construction operations.

Smarter, Safer, More Efficient

The construction industry has long struggled with stagnant productivity and thin margins. Automation and AI offer a path not just to safer work, but to a more productive and profitable sector, benefitting companies, workers, and clients alike. As manual processes become smarter and more efficient, the economic gains are starting to flow. Projects get completed faster and with fewer costly mistakes, meaning contractors can take on more work or deliver higher quality within the same budget. Workers, in turn, can be more productive and potentially earn higher wages in skilled tech-assisted roles. And society benefits from infrastructure and buildings delivered on time and on budget.

One of the headline advantages is productivity improvement. Various studies have suggested that broad adoption of automation and digital technology could boost construction productivity by 30-50% over time. Consider what that means: an industry that has notoriously lagged others (like manufacturing) in efficiency could finally start catching up. With robots handling repetitive tasks around the clock, projects that used to take 18 months might finish in a year. For example, if bricklaying robots and automated mixers accelerate the wall construction phase, the follow-on trades (electricians, plumbers) can start sooner, compressing the schedule.

Faster project delivery means significant cost savings on overhead and earlier revenue generation for owners. It also allows firms to tackle more projects in a season than before, growing their business without necessarily growing their headcount proportionally.

Safety improvements also translate to economic benefits. Construction accidents and injuries cost companies enormous sums each year in medical expenses, lost work time, insurance, and legal costs. By reducing on-site accidents through automation (robots don’t fall off scaffolds or get fatigued, after all), firms can save on these hidden costs. A safer workflow also means less downtime, sites don’t get shut down for investigations, and morale remains higher when workers feel protected.

Some early adopters of AI safety systems have reported up to 25% fewer on-site accidents after introducing real-time monitoring and alerts. Fewer injuries not only avoid expenses but also help address labour shortages by keeping experienced workers on the job and attracting new entrants who see the industry becoming safer.

Another economic angle is optimal resource use and less waste. AI-driven planning tools optimize everything from earthwork (moving the right amount of dirt, not excess) to logistics (ensuring materials arrive just-in-time). Drones and sensors help track inventory and prevent over-ordering. Automated machines can measure and mix materials precisely, so less concrete or asphalt is wasted.

Over a large project, these efficiencies add up to significant cost savings. For example, a prefabrication approach with robotic assistance can reduce material waste to near-zero and cut onsite labour needs dramatically. When a Swedish modular builder employed robotic production lines, they slashed on-site labour by 60% and cut project timelines by nearly a third. Time is money in construction, so every week shaved off the schedule or every rework incident avoided improves the bottom line.

Importantly, workers themselves stand to gain economically from this smarter workflow. As menial tasks are automated, the remaining human roles tend to be higher-skilled and better-paid. For instance, a technician who maintains and programs robotic equipment or a drone operator analysing survey data can command higher wages than a general labourer doing manual lifting. Moreover, by making construction jobs less physically punishing and more technology-driven, the industry can attract a new generation of talent and retain them longer. This helps alleviate chronic labour shortages, which in turn prevents wage inflation from too few workers chasing too many projects. In the long run, a more productive industry can afford to pay its skilled workforce more while still delivering value to clients.

One can also look at the macro-economic uplift of embracing construction technology. Major infrastructure programs and housing initiatives become more feasible when you can do more with less labour. Governments and investors are keen on the promise that a “smarter” construction sector can build the roads, bridges, and cities of tomorrow without being bottlenecked by workforce limitations.

In regions where demographic trends threaten the labour pool, like parts of Europe and East Asia, automation is increasingly seen as essential to sustaining the construction industry’s output. In short, efficiency gains from technology are not about cutting jobs, they are about enabling more work to be completed with the talent we have, and creating capacity to take on new ambitious projects that would otherwise be out of reach.

There is a virtuous cycle at play: safer and more efficient workflows make construction more attractive and sustainable as a career, which helps bring in the next wave of workers, who in turn will leverage technology even further to deliver great projects. The industry, often criticized for its slow productivity growth, could finally shed that label, and everyone from business owners to the craft workers on site stands to benefit when construction becomes synonymous with innovation and high performance rather than manual drudgery.

From Robot Technicians to Digital Managers

A common misconception is that automation will simply eliminate construction jobs. In reality, it’s reshaping the job landscape, not erasing it. As certain manual tasks diminish, entirely new tech-centric roles are emerging in their place, roles that were rarely seen on sites a decade ago.

This shift is analogous to how the advent of computers created IT departments and software developers; in construction, we’re now seeing the rise of specialists who focus on the machines and data that drive modern projects. These are the new job families of the smart construction era, and they’re in growing demand:

Robotics Technicians and Operators

Perhaps the most obvious new role is the person who keeps the robots up and running. Every piece of automated ki, whether it’s a bricklaying robot, a drone fleet, or an autonomous bulldozer, needs skilled technicians to program it, maintain it, and troubleshoot issues. Robot technicians are the mechanics and IT support rolled into one for construction robots. They might calibrate sensors, swap out robot parts, and update software to adjust the robot’s behaviour for different tasks. On large projects, it’s easy to imagine a crew of technicians in the morning not with hammers but with laptops and toolkits, making sure the day’s robotic helpers are all systems go.

The robot operator is a related role: for example, a trained individual might oversee multiple robotic bricklaying units, ensuring they are loaded with materials and aligned correctly, effectively acting as a supervisor for a team of robots. These jobs require a mix of understanding construction fundamentals and being tech-savvy with programming and electronics. They are also good middle-skill jobs that offer career growth, today’s robot operator could become tomorrow’s robotics project manager as the field expands.

Industry forecasts suggest that by the early 2030s roles like “Robotics Specialist” will be common on large sites to achieve the same work with smaller human crews. Companies might employ 2-3 human workers to manage a cluster of robots, rather than a dozen laborers doing the work directly.

Digital Construction Managers / BIM Managers

Construction management itself is becoming a more digital profession. Digital project managers or BIM (Building Information Modeling) managers are specialists who administer the digital twin of the project. They ensure that the design models, schedule, and site data all integrate in a coherent digital workflow. These professionals orchestrate how information flows from the office to the field devices. For instance, a digital site manager might spend their day updating the 3D model as changes occur, then pushing that update out to workers’ tablets and AR glasses so everyone is literally on the same page.

They might also manage collaborations between various software platforms (coordination between design software, project management tools, and on-site sensors). As AI tools become part of project management systems, someone needs to configure those AI “co-pilots” and interpret their output. Thus, project managers with strong tech backgrounds, or IT professionals embedded within construction teams, are increasingly valued. Many firms are creating dedicated Innovation Manager or Construction Technologist positions to champion these new systems.

These roles blend knowledge of construction processes with the ability to leverage data and digital tools to optimize those processes.

AI and Data Analysts in Construction

With the explosion of data on sites (from drones, IoT sensors, wearables, etc.), there’s a growing need for roles that can make sense of all this information. An AI safety analyst, for example, might be tasked with monitoring the feeds from computer vision safety systems, they review the alerts where AI thinks someone wasn’t wearing a helmet or a machine got too close to an edge, and then determine the appropriate response.

They also fine-tune the AI by feeding it more data or adjusting its sensitivity to reduce false alarms. Similarly, firms are hiring data analysts who focus on project performance data, generating insights like “which activities are consistently causing delays” or “predictive maintenance schedules for our equipment based on sensor readings.”

These analysts often use dashboards and AI tools themselves, but their human insight is needed to ask the right questions and communicate findings to decision-makers. Such roles didn’t exist on site before, they might have been done ad-hoc by a project engineer, but now the volume of data merits dedicated personnel. As one industry analysis noted, physical and manual skills will still be essential, but a portion of the workforce is shifting to roles that blend technical know-how with construction experience.

In practice, that might look like a veteran superintendent who learns data analytics and transitions into an operational excellence role, using numbers to drive site improvements across the company.

Specialist Operators (Drones, 3D Printers, etc.)

New technologies also create niche operator roles. We already see drone pilots and UAV specialists becoming part of construction teams, often as consultants or in-house experts who handle all aerial data collection. As 3D printing of construction elements grows, companies will need 3D printing technicians who can set up and monitor printers that fabricate building components or even print houses on site.

These technicians ensure the printer has the right material mix, the nozzle is laying properly, and the machine’s software is correctly interpreting the digital design. There are also sustainability specialists and energy modelers being hired to focus on green building tech (though not purely a result of automation, it’s another new career path intersecting with construction’s modernization). Each of these specialties represents a career path that barely existed a short while ago.

What’s encouraging is that many of these emerging jobs are attractive to a younger, more diverse workforce that might have been hesitant to enter construction before. The image of construction work is being elevated from solely manual toil to a more high-tech, innovative field. This is drawing in talent with backgrounds in robotics, software, and engineering who might otherwise have gone into other industries.

Meanwhile, existing tradespeople are upskilling, taking courses in operating drones, learning coding basics for machinery, or getting certified in BIM software, to transition into these new roles. Lifelong learning is becoming the norm on the construction site of the future.

It’s worth noting that traditional roles are not disappearing overnight. Carpenters, electricians, equipment operators, plumbers, these professions are still indispensable. But their skill sets are broadening. The carpenter of the future might also be a part-time CNC machine operator for cutting timber components, and an electrician might become adept at installing not just wires but also the sensors and networks that connect smart building systems.

The overarching trend is clear: the construction workforce is becoming more specialized, more technical, and more collaborative with machines. And that opens up opportunities for career advancement and higher wages for those willing to ride the wave of change.

Job Fears vs. Reality

Whenever automation is discussed, there’s an underlying fear: will the robots take away all the jobs? In construction, this concern is certainly present, heavy equipment operators wonder if autonomous vehicles will side-line them, laborers worry that robots could replace crews, and young people question if the career has a future. However, the evidence so far points to a more nuanced reality: while some job roles will diminish, new ones will be created, and overall the workforce will evolve rather than vanish. Understanding the fears vs. realities is important for industry leaders and workers alike to navigate this transition.

First, the fear of mass job loss due to automation in construction does not match the current data or the practical challenges of the industry. Construction is fundamentally different from a factory, every project is unique, environments are uncontrolled, and coordination is complex. This inherent variability means it’s extremely hard to automate everything on a construction site.

Many tasks still require human flexibility, problem-solving on the fly, and the ability to deal with the unexpected (like weather changes or design alterations). Robots excel at specific repetitive tasks in structured conditions, but they struggle with the unpredictability of, say, a renovation of a century-old building where nothing is plumb or level. As a strategy report quipped, in construction “every job site is different, there’s no standard procedure a robot can follow for all cases”.

While robots will handle more routine work, skilled tradespeople will continue to be indispensable for a long time, especially for tasks that are one-off or require a creative touch.

In fact, we’re already seeing evidence that technology can coincide with employment growth. For example, the U.S. solar installation sector introduced a lot of automation in recent years (like robotic panel installation and automated surveying), yet solar industry employment actually grew by 5.3% alongside those innovations. Similarly, countries that heavily embrace automation often see shifts in workforce rather than shrinkage.

One study noted that despite increased automation, the overall construction workforce can expand, workers move into higher-skilled positions created by the new technology. It’s also telling that many construction firms are not using tech to cut headcount, but to fill the gap from labour shortages. In markets like North America, there are hundreds of thousands of unfilled construction jobs. Automation is arriving not to displace workers, but because there aren’t enough workers to begin with, and projects still need to get built. This flips the narrative: robots in construction are as much about solving a labour crisis as they are about efficiency.

The reality is some job roles will diminish or disappear, and this needs to be managed. For instance, if a crew of 10 manual surveyors is replaced by 3 surveyors with drones and a data analyst, that is a reduction in traditional surveying jobs. We might see fewer general labourer positions as tasks like hauling materials or basic digging become automated. However, many of those roles are being replaced by the new roles we discussed (robot operators, etc.), often filled by the same people after retraining. A labourer might evolve into a robot tender, a surveyor might retrain as a drone pilot.

The construction workforce of the future will likely be smaller in some of the pure “strong back” categories but larger in tech-enabled categories. Economic history shows that technology tends to create more jobs than it destroys in the long run, though the transition can be challenging. During the shift to mechanization in the 20th century, for example, construction lost many purely manual jobs (like large crews for digging by hand) but gained jobs in operating machinery, manufacturing building components, and designing more complex structures. The net effect was more output and generally more employment.

A key to easing current fears is investment in reskilling and training. Many construction firms and unions are already beginning to offer training programs to upskill workers, teaching a robotic total station layout, running semi-automated equipment, or using BIM software. There is a concerted effort to ensure that today’s workforce can fill tomorrow’s roles. The workers themselves often find that learning to work with technology makes their jobs more engaging and extends their careers (for example, an aging equipment operator can transition to an operations tech role and work longer with less physical strain). Apprenticeship programs are also evolving to include digital literacy alongside traditional craft skills, so new entrants are prepared for a hybrid job environment.

It’s also worth addressing the psychological aspect: change is hard, and there is understandable anxiety about new technology. Transparent communication from management, inclusion of workers in technology trials, and highlighting success stories can help. When crews see, for instance, that a drone isn’t there to replace them but to take the risky task of climbing on a roof for inspection, and that one of their own has become the certified drone pilot, it humanizes the change. Over time, as machines prove to be partners rather than threats, trust builds. Notably, some regions report a shift in sentiment: over 80% of European employees surveyed viewed robotics positively, recognizing that collaborative robots (cobots) can make their work easier and more interesting.

In summary, the fear that automation will devastate construction jobs is unlikely to materialize in the foreseeable future. Instead, the industry is headed toward a blended workforce of humans and machines. People will do what they do best, creative problem solving, adapting to surprises, ensuring quality and safety, and machines will do what they do best, relentless repetition, heavy lifting, precise calculations. The future is about collaboration, not replacement. And as long as the industry invests in its people as much as its technology, the workforce can grow in expertise and even in numbers. The construction careers of tomorrow may look different, but they can be just as fulfilling and far safer than those of yesterday.

A New Era of Construction, Everywhere

The march of construction automation is a global phenomenon, but it’s unfolding at different paces and in different ways around the world. Regional factors, such as labour costs, demographic pressures, government policies, and market scale, influence how quickly and in what form technologies are adopted.

A look at major regions shows a common direction towards human-machine collaboration, with some interesting twists:

China

China stands out as a powerhouse in embracing robotics and AI across industries, including construction. The country accounts for half of the world’s industrial robot installations, and Chinese construction firms are increasingly turning to automation to keep up with breakneck development and an aging workforce. The government’s strategic plans explicitly call for “high-quality workers with technical skills” and “global leadership in robotics”, underscoring national support for automation and reskilling.

On sprawling construction sites for megaprojects, it’s not uncommon to see robotic total stations and drone swarms surveying land, or automated precast factories churning out modules for high-rise apartment blocks. Chinese companies have piloted 3D-printed houses and even used robots for intricate tasks like rebar tying and bricklaying, though often in controlled environments. A major driver is demographics: China’s working-age population is shrinking, so automation is viewed as essential to maintain growth. More than 90% of Chinese companies surveyed identified AI and robotics as key transformative technologies for their business.

In practice, this means heavy investment in tech like prefabrication and off-site automation to produce building components with minimal labour, and rapid adoption of digital project management. However, China’s scale also means human labour is still widely used, the transition is gradual. We see a dual strategy: automate wherever efficient, and upskill millions of workers to operate the new systems. The result is that China is often ahead of the curve in deploying new construction tech at scale (for example, using robot plastering machines on large housing developments), setting a precedent that other countries observe closely.

Middle East (Gulf Region)

The Middle East, especially the Gulf states, have emerged as bold adopters of construction automation for somewhat different reasons. Here, the push comes from ambitious mega-projects and a drive for efficiency. Countries like the UAE and Saudi Arabia are planning and building entire futuristic cities (see: Neom in Saudi Arabia, or various smart city initiatives in the UAE) on tight timelines. Traditional methods simply cannot deliver these at the required speed or with the limited local workforce available.

As a result, Middle Eastern developers are investing heavily in robotics and automation as a necessity. For instance, Saudi Arabia’s Neom has partnered with international firms to develop robotic systems that could reduce on-site construction labour by up to 90% through off-site automation. This means using robotic assembly lines to build modular sections of buildings in factories and then assembling them on site, drastically cutting the manpower needed under the desert sun. Major contractors in the region like ALEC in the UAE have been early movers, ALEC began a dedicated robotics strategy in 2017 and has since trailed over 100 robotic solutions ranging from drilling and painting robots to autonomous site cleaners.

Drones for survey and progress tracking are already standard on large projects in Dubai and Abu Dhabi. The region also isn’t shy about bold goals: ALEC aims for 5% of all site activities to be robotic by 2030, and experts predict perhaps 20% of construction sites in the Gulf will feature some robotic activity in the next five years. Government support is evident too, Dubai, for example, launched a 3D Printing Strategy, mandating that a certain percentage of new buildings incorporate 3D printed components.

While not all experiments have panned out (3D printing entire buildings is still somewhat in the “hype” phase as panellists at a recent UAE tech conference noted), the overall trajectory is clear. In the Middle East, robots are viewed as allies to achieve the extraordinary scale of development planned, and there is less public resistance given the transient expat labour dynamics. Interestingly, rather than displacing local workers (many construction laborers are foreign), automation here is seen as upgrading the industry and providing higher-skilled tech jobs for citizens, aligning with economic diversification goals.

Europe

Europe’s construction sector faces high labour costs, an aging skilled trades base, and strong regulatory pressures, all nudging it towards automation, albeit in a measured way. Many European countries have stringent safety and sustainability standards, which technology can help meet. For instance, robotic and automated systems are being used in Europe to achieve higher precision and reduce waste, supporting the EU’s sustainability goals.

Scandinavian countries and Germany are leaders in prefabrication and digital construction, Sweden’s aforementioned use of robotic modular factories is one example. In Finland and the UK, construction firms have enthusiastically adopted drones, BIM, and AI-based safety monitoring (with one UK contractor seeing a 40% drop in safety incidents after rolling out AI vision and wearables). However, Europe also has a very traditional and fragmented construction industry, many small firms are slower to invest in expensive robots.

The EU and national governments are actively funding research and pilot projects to demonstrate automation benefits. A global survey reported that 81% of construction businesses plan to increase use of robotics in the coming decade to address skill shortages and safety, and European respondents mirror that optimism. The difference is that Europe often emphasizes collaborative robots (cobots) and augmenting workers rather than outright replacement. With strong labour unions in some countries and a cultural pride in craftsmanship, European automation tends to focus on assisting trades, for example, power tools with AI that reduce vibrations or exoskeletons that help older workers continue in the field.

Policy-wise, Europe’s focus on digitalization (mandating BIM for public projects in many countries) is laying the groundwork: once workflows are digitized, introducing robotics and AI becomes easier. So while you may not yet see robots “swarming” European building sites at night (a vision some futurists have), you will find robotic arms in factories building timber panels, drones inspecting historical structures in France, and AI planning software optimizing construction logistics in the Netherlands.

Over the next decade, as skilled workers retire in droves, expect Europe to lean more on automation out of sheer necessity, and to train the next generation of builders to be as much computer operator as craftsperson.

North America

In the United States and Canada, the adoption of construction automation has been picking up speed after a relatively slow start. The North American construction industry is highly dynamic but was traditionally fragmented and cost-sensitive, relying on abundant labour (including migrant labour). Now, severe labour shortages, the US construction sector needed an additional ~546,000 workers in 2023 to meet demand, and a tech boom are spurring change.

Silicon Valley and other tech hubs have trained their sights on construction’s inefficiencies, leading to a wave of construction tech start-ups. Many of the robotics innovations making headlines originate in the US: Built Robotics (autonomous earthmoving machines), Dusty Robotics (layout printing robots), Canvas (drywall finishing robot), SkyMul (rebar-tying drones), and others. These start-ups often partner with established contractors to pilot their technologies on real projects. The result is that in pockets, say, a big infrastructure project in California or a high-rise in Boston, you might already find an autonomous excavator digging trenches or a robot dog scanning as-built progress each evening.

Large US construction firms, like Turner or Bechtel, have whole innovation teams integrating such tools and sharing lessons across job sites.

At the same time, AI and software are transforming construction management in North America. Project management platforms with AI (e.g., Autodesk Construction IQ) were born here and see wide use in flagging safety or quality issues from daily reports. The concept of AI co-pilots resonates strongly, with companies like HCSS launching an AI assistant for construction and numerous builders using predictive algorithms to manage risk. The North American market also highly values safety improvements, expect increasing mandates or incentives for technologies that demonstrably improve safety records, such as automated rigging checks for cranes or smart barriers for work zones.

One distinctive aspect in the U.S. is the role of construction unions and workforce organizations: historically cautious about anything that might reduce jobs, many unions are now engaging with automation by negotiating training and new classifications for robotic equipment operators rather than fighting the tech outright. They recognize that the workforce is aging (the average construction worker in the U.S. is in their 40s) and that younger workers might be more attracted to a tech-infused industry. Thus, there’s a push to include robotics and VR training in apprenticeship halls.

North America also includes Canada, which similarly faces labour shortages and cold weather construction challenges that spur use of off-site prefab and automation. Canadian firms have been exploring robotics for remote or dangerous tasks (like mining or work in the far north) that can be adapted to construction.

In all, North America’s adoption of construction automation is characterized by innovation and pilot projects blossoming into wider adoption. We’re now seeing a shift from experimentation (where in 2024 about 1.5% of U.S. firms were using AI) to early majority use, for instance, a 2024-2025 dip in the percentage of companies experimenting with robotics was noted as moving from pilots to real deployments. Over the next few years, expect to see robotics and AI becoming a competitive differentiator, contractors who leverage them may outbid and outperform those who don’t, accelerating industry-wide uptake.

Around the globe, the message is consistent, automation and AI are redefining how construction work is done. But nowhere is the human element being written out.

Whether it’s Europe’s collaborative approach, China’s mass re-skilling programs, the Middle East’s tech-driven upskilling of its workforce, or America’s entrepreneurial innovation coupled with training, each region is charting a path to integrate machines without losing the value of human expertise. Construction may be entering a high-tech era, but it remains a fundamentally human endeavour, built by and for people, with technology as a powerful tool to do it better.

Building the Future Together

As the dust settles on this new era of construction, one thing is clear: the future of building will be written by humans and machines working in tandem. The narrative is no longer one of competition between labour and automation, but of collaboration. When a drone maps a site in minutes, it’s a human who analyses the map to make design tweaks. When an AI flags a safety hazard, it’s a human safety manager who enforces the solution. When a robot lays bricks, it’s under the watchful eye of a skilled mason ensuring everything is just right. Each complements the other.

For construction professionals, this convergence of hard hats and high tech brings exciting opportunities. The industry is shedding some of its historical dangers and inefficiencies, becoming smarter and more responsive. Careers in construction are expanding beyond the traditional paths, a young person entering the field today might become a robot foreman, an AI-supported project planner, or a sustainability data specialist, roles that barely existed a generation ago. What remains constant is the need for construction expertise: knowing how a building comes together, how to solve on-site dilemmas, how to manage a team, these are human skills that machines can’t replicate.

Technology is there to empower, not overpower. It empowers workers by taking away the drudgery and danger, giving them tools to be more precise and creative. It empowers companies by unlocking productivity and enabling the delivery of complex projects that once seemed impractical. And it empowers the industry as a whole by attracting fresh talent who see construction as a cutting-edge field where they can innovate, not averse to change but rather driving change.

Naturally, the transition isn’t without challenges. Companies will need to invest in training and change management. Workers must embrace lifelong learning. Policymakers and educational institutions have a role in smoothing the path, from updating building codes to accommodate new methods, to expanding vocational curricula to cover robotics and AI. But the momentum is here. Around the world, construction is pivoting from a predominantly manual craft to a tech-augmented profession.

Ultimately, the measure of success will not be how many robots are on a jobsite, but how much better construction becomes for people, safer work conditions, higher quality structures, more sustainable practices, and rewarding careers. The early signs are encouraging: injuries down, output up, and a new generation of constructors who are as comfortable with a tablet as a trowel. As one veteran industry leader aptly summarized the journey: “The construction industry is on the cusp of a digital revolution, with automation and robotics leading the charge in improving project outcomes.”

In this revolution, it is humans plus machines, not one without the other, that will build our roads, cities, and skylines. The construction workforce is not being replaced; it’s being reborn with new skills and possibilities. Technology, empowerment, and the future of work in construction are all interlinked. By embracing that synergy, construction can achieve feats in the coming years that were previously unimaginable, all while uplifting the people who make it happen. The foundation is laid, now it’s time to build the future, together.