Biology Meets Mining and AI to Unlock Critical Minerals

Rare earth elements and critical minerals have moved from niche scientific interest to strategic necessity. Materials such as cobalt now sit at the heart of modern energy systems, from electric vehicle batteries and grid scale storage to advanced alloys used in aerospace and defence manufacturing. Demand has surged at a pace few predicted, while supply remains constrained by geology, geopolitics, and the environmental cost of conventional extraction.

Against this backdrop, attention is shifting toward unconventional sources. Mine tailings, industrial wastewater, and other low concentration streams were once dismissed as uneconomic. Today, they are increasingly seen as untapped reservoirs of value. Recovering useful materials from these streams would not only ease supply pressure but also reduce waste and environmental impact. That is precisely where a new research effort from Ames National Laboratory enters the picture.

Rethinking How Metals Are Captured

Scientists at Ames Lab have secured funding to pursue a radically different approach to critical mineral recovery, one rooted in biology rather than brute force chemistry. Instead of relying on energy intensive separation processes, the team is looking to nature for inspiration. Living systems have been binding, transporting, and storing metals efficiently for billions of years. The challenge lies in adapting those systems for industrial use.

At the centre of the project is an ambitious plan to combine synthetic biology, machine learning, automated laboratory platforms, and molecular modelling into a single discovery pipeline. The goal is to design biological systems capable of selectively capturing metals like cobalt from dilute and complex mixtures such as mine tailings and wastewater streams.

Learning From Nature’s Playbook

According to project lead Peng Xu, nature already provides a blueprint for efficient metal capture: “Nature already has ways of capturing metals efficiently. Our approach takes this biological process to the next level by using specialized cellular components that act as intracellular metal depositories in certain bacteria.”

Certain microorganisms naturally accumulate metals as part of their metabolic processes. These metals may serve as enzyme cofactors or structural components, safely stored inside the cell. By identifying and adapting the molecular machinery behind these processes, the Ames Lab team aims to redirect that natural efficiency toward industrial mineral recovery.

The focus on intracellular metal depositories is particularly significant. Rather than binding metals on the outside of a cell, which can limit capacity and selectivity, internal storage allows for higher accumulation and greater control. This opens the door to systems that are both efficient and highly specific.

Cobalt in the Spotlight

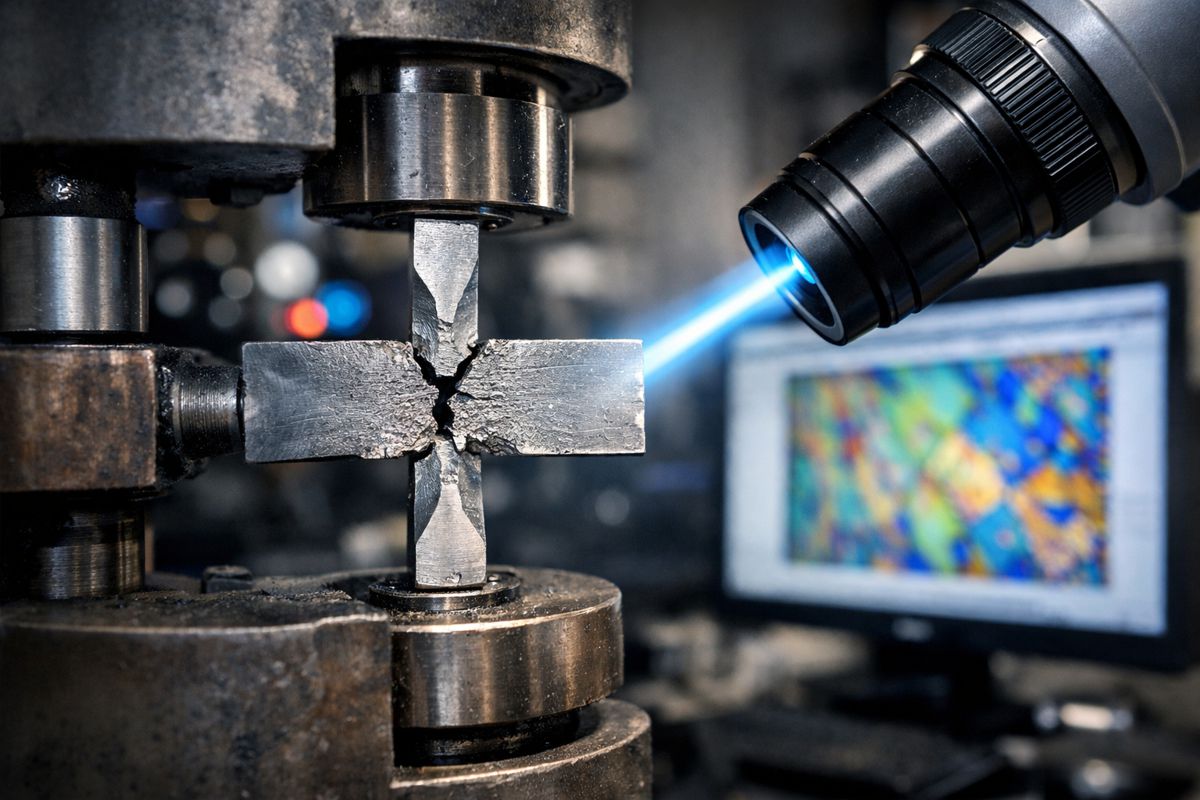

While the underlying platform could eventually target a wide range of critical materials, cobalt has been prioritised as an early proof point. The choice is hardly accidental. Cobalt plays a crucial role in lithium ion batteries, improving energy density and thermal stability. It is also used in superalloys that must perform reliably under extreme temperatures and stresses.

Global cobalt supply chains are under growing scrutiny due to concentration of production and ethical concerns around mining practices. Developing alternative recovery pathways from secondary sources could help diversify supply while reducing environmental and social risks.

To tackle this challenge, the team is adapting natural biological systems to bind and store cobalt with precision. This is where automation and artificial intelligence become essential.

Accelerating Discovery With AI and Automation

Traditional laboratory experimentation can be slow and labour intensive, particularly when exploring vast molecular design spaces. The Ames Lab team is sidestepping this limitation by deploying an automated laboratory platform tightly integrated with AI driven design tools.

Artificial intelligence will be used to identify and design large numbers of peptides, short chains of amino acids capable of binding specific metals. These candidates can then be rapidly synthesised and tested using automated systems, allowing the researchers to quickly identify those with the strongest and most selective affinity for cobalt and other target minerals.

This approach dramatically shortens development cycles. Instead of testing a handful of options, the team can evaluate hundreds or thousands, refining designs with each iteration. The result is a discovery process that is faster, more precise, and far more adaptable than conventional methods.

Where Disciplines Converge

The project’s success depends on genuine collaboration across scientific boundaries. Chemistry, biology, physics, and data science are not operating in isolation but as parts of a tightly integrated whole. Xu emphasised the importance of this interdisciplinary approach: “This is truly a project that requires theory, AI, and experiments, across chemistry and biology, working together. It’s highly interdisciplinary effort, seeing it come together is really exciting.”

Such integration is not always easy, but it plays to the strengths of Ames Lab. The laboratory has a long history of bringing together diverse expertise to tackle complex materials challenges, supported by advanced facilities and a collaborative research culture.

From Lab Bench to Scalable Systems

Early stage research often falters when promising ideas prove difficult to scale. The Ames Lab team is addressing this risk from the outset. Once a working biological capture system is established, automation and AI will again be used to optimise performance and explore pathways toward larger scale application.

The long term vision is a modular platform that can be tailored to different materials and feedstocks. Such a system could be deployed at mine sites to treat tailings, integrated into wastewater treatment facilities, or adapted for industrial recycling streams. Flexibility is a key advantage, particularly in a world where material demand and availability are constantly shifting.

Importantly, the researchers believe their approach could be significantly less costly than traditional recovery methods. Lower energy requirements, reduced chemical use, and the ability to operate on low concentration sources all contribute to improved economics.

A Team Effort Backed by Federal Support

In addition to Xu, the project brings together co principal investigators Ratul Chowdhury, Marit Nilsen Hamilton, Larry Halverson, and Long Qi. Each contributes specialised expertise, reinforcing the interdisciplinary foundation of the work.

The research is supported by the U.S. Department of Energy through its Office of Science, Office of Biological and Environmental Research, and Biological Systems Science Division, under the 2025 Lab Critical Materials and Minerals Pilot Program, which reflects the strategic importance of developing resilient and sustainable supply chains for critical materials.

A Broader Mission With Global Implications

Beyond this specific project, Ames Laboratory’s work reflects a broader mission. As a U.S. Department of Energy Office of Science National Laboratory, it focuses on creating innovative materials, technologies, and energy solutions to address global challenges.

The Office of Science remains the single largest supporter of basic research in the physical sciences in the United States. Its investment in projects like this one signals a recognition that future materials security will depend as much on biology and data science as on geology and mining equipment.

Building a More Resilient Minerals Future

Recovering critical minerals from unconventional sources is no longer a speculative idea. It is becoming an essential strategy for balancing economic growth, environmental responsibility, and energy security. By blending biological insight with AI driven design and automation, the Ames Lab team is charting a course toward recovery methods that are smarter, cleaner, and more adaptable.

If successful, this work could reshape how industries think about waste, turning liabilities into assets and helping ensure a more resilient supply of materials that underpin modern life.