Cincoze Pioneer a New Class of Industrial Edge Intelligence

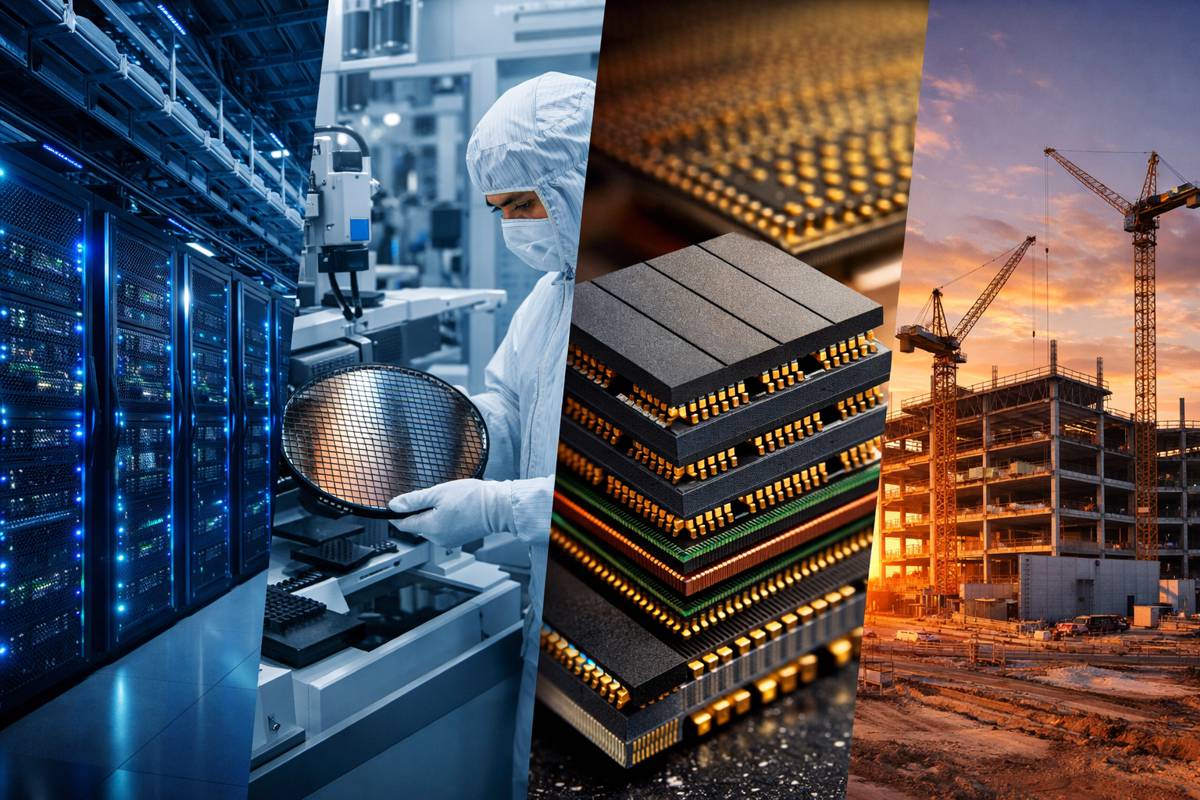

Manufacturing floors are changing shape. What was once dominated by programmable logic controllers and isolated automation cells is now evolving into data-rich environments where machines do more than repeat instructions. They observe, interpret, and respond in real time. At the heart of this shift sits edge computing, increasingly recognised as the real-time brain of modern production lines.

Rugged edge computing brand Cincoze has introduced a new high-performance DIN-Rail computer series designed precisely for this role. The MD-3000 series represents the flagship of its Machine Computing MAGNET product line, engineered to support vision-driven smart manufacturing where latency, reliability, and scalability are non-negotiable. Since its launch, interest from system integrators has accelerated quickly, reflecting the growing demand for computing platforms that can survive industrial environments while delivering desktop-grade performance at the edge.

Rather than acting as a passive controller, the MD-3000 is positioned to analyse images, process sensor data, and issue responses in real time. In practical terms, this allows production equipment to see, judge, and act directly on the factory floor without waiting for cloud-based decision making.

Why Edge Computing Has Become Mission Critical

As manufacturing adopts machine vision, artificial intelligence, and robotics, the limitations of traditional architectures have become obvious. Shipping raw image data to a central server introduces latency, consumes bandwidth, and raises reliability concerns in harsh environments. Edge computing addresses these challenges by placing powerful processing resources as close as possible to the source of data.

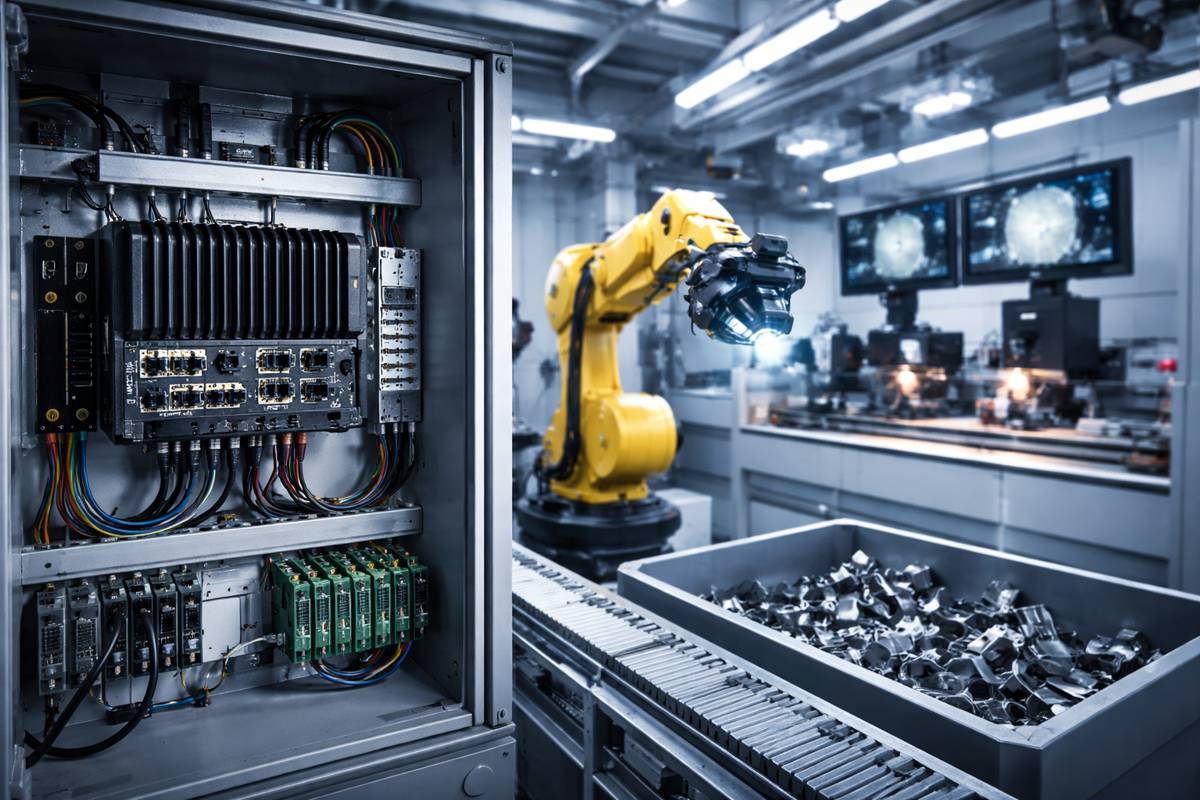

In vision-driven applications, milliseconds matter. Whether a robotic arm is identifying a part in a bin or an inspection system is rejecting a defective component, delays translate directly into inefficiency, waste, or production stoppages. The MD-3000 series is designed around this reality, combining computing density with industrial-grade robustness in a form factor suited for control cabinets and equipment enclosures.

The system’s compact 150 mm chassis height allows it to sit comfortably alongside PLCs, I/O modules, and power supplies, while its DIN-Rail mounting enables rapid deployment and straightforward maintenance.

Performance That Keeps Pace With Vision and AI

At the core of the MD-3000 platform is desktop-grade processing power. The system supports up to 14th Generation Intel Core processors operating in the 35 to 65 watt range, delivering the computational headroom required for advanced image recognition, deep learning inference, and real-time motion control.

This level of performance is particularly relevant for machine vision workloads, where high-resolution cameras, complex algorithms, and tight timing constraints converge. High-speed computing and low-latency response ensure that image recognition remains synchronised with mechanical actions, avoiding the drift and delays that undermine automation accuracy.

Thermal stability plays a decisive role in sustaining this performance. The MD-3000 integrates two patented technologies designed specifically for industrial conditions. The Dynamic Thermal Mechanism optimises heat dissipation under variable workloads, while Smart Over Temperature Protection actively safeguards system integrity when operating conditions push beyond safe thresholds. Together, these features allow the platform to maintain consistent performance without compromising longevity.

Smart Bin Picking Moves From Concept to Reality

Among the most demanding applications in smart manufacturing is automated bin picking. This process, critical to materials handling automation, requires robotic systems to identify, locate, and retrieve parts randomly arranged within containers.

By combining 3D vision with AI algorithms, robotic arms can now detect object geometry, determine optimal grasp points, and calculate motion trajectories in real time. However, the effectiveness of these systems depends heavily on the stability and responsiveness of the underlying computing platform.

The MD-3000 is well suited to this environment. Its processing capabilities enable real-time image recognition and trajectory calculation, ensuring coordinated operation between vision systems and robotic actuators. Installation is simplified by the standard DIN-Rail mount, allowing the system to be installed directly into control cabinets. Operational interfaces and maintenance access are positioned on the front panel, reducing downtime and improving serviceability in confined spaces.

In high-throughput production environments, these practical considerations often determine whether an automation project scales successfully or stalls during deployment.

Appearance Inspection as the Backbone of Quality Control

Automated appearance inspection has become central to quality assurance across multiple manufacturing sectors. High-resolution cameras paired with deep learning algorithms can identify surface defects, foreign objects, misalignments, and labelling errors at speeds far beyond human capability.

Such systems place heavy demands on I/O flexibility and data handling. Production lines vary widely in lighting setups, trigger mechanisms, camera configurations, and storage requirements. A rigid computing platform quickly becomes a bottleneck.

The MD-3000 addresses this challenge through a modular and scalable design. Available in configurations supporting two, four, or six expansion slots, the system accommodates more than a dozen function modules. These include digital and analogue I/O, Power over Ethernet, M.2 expansion, and support for 2.5-inch storage devices. This modularity allows system integrators to tailor configurations precisely to each inspection task without overengineering the solution.

Despite this flexibility, the compact footprint remains comparable to that of a PLC. With a chassis height of just 150 mm, the MD-3000 fits comfortably into space-constrained inspection cabinets, offering a significant advantage where control space is at a premium.

Dimensional and Precision Inspection at Industrial Scale

Dimensional inspection represents the final safeguard before parts move downstream or reach customers. When combined with 2D or 3D vision, laser measurement, or structured light technologies, inspection systems must process vast volumes of geometric data while maintaining strict accuracy thresholds.

Edge computing platforms in this domain must balance performance with reliability. Any interruption can compromise measurement integrity or halt production entirely. The MD-3000’s architecture supports this balance by enabling high-speed data processing at the source while maintaining industrial resilience.

The platform supports expansion with wireless and communication interfaces including WiFi, GSM, and GNSS. This enables inspection data to be transmitted instantly to central systems for analysis, traceability, and long-term process optimisation. Such connectivity is increasingly important as manufacturers adopt digital quality records and predictive analytics.

Built for Harsh Industrial Environments

Reliability under adverse conditions remains a defining requirement for industrial computing. Factory floors expose equipment to vibration, electrical noise, temperature extremes, and fluctuating power conditions.

The MD-3000 series is engineered to withstand these realities. It operates across a wide temperature range from minus 40 degrees Celsius to 65 degrees Celsius and supports wide voltage input from 9 to 48 volts DC. Compliance with industrial electromagnetic compatibility standards, including EN 61000-6-2 and EN 61000-6-4, further underlines its suitability for electrically noisy environments.

These characteristics make the platform a dependable foundation for high-precision measurement systems, robotic cells, and inspection stations where failure is not an option.

The Edge as the Factory’s Real-Time Brain

As smart manufacturing matures, the role of edge computing continues to expand. Systems like the MD-3000 no longer serve as simple controllers but act as intelligent intermediaries between sensors, machines, and enterprise systems.

By enabling equipment to see through machine vision, judge through AI-driven analysis, and act through real-time control, edge platforms are redefining how automation is designed and deployed. For system integrators and manufacturers alike, the focus is shifting from raw connectivity to dependable, scalable intelligence at the edge.

The MD-3000 series reflects this transition. Its combination of computing performance, modular expansion, compact design, and industrial resilience positions it as a practical computing platform for machine vision and smart manufacturing applications where decisions must be made instantly and reliably.