Siemens Brings the Industrial Metaverse to Life with Digital Twin Composer

Industrial digitalisation has reached a point where disconnected models, static simulations and siloed data are no longer enough. Manufacturers, infrastructure owners and operators are facing a perfect storm of rising complexity, tighter margins, supply chain volatility and growing sustainability expectations. Against that backdrop, Siemens has introduced Digital Twin Composer, a new software solution designed to build industrial metaverse environments at scale and make virtual decision making practical, fast and reliable.

Announced at CES 2026, Digital Twin Composer brings together industrial AI, high fidelity simulation and real time physical data in a single managed environment. The goal is not visual spectacle, but operational clarity. By allowing organisations to experience products, processes and facilities virtually before physical work begins, Siemens is positioning Digital Twin Composer as a core tool for reducing risk, accelerating delivery and improving capital efficiency across the industrial lifecycle.

Connecting Virtual Models with the Physical World

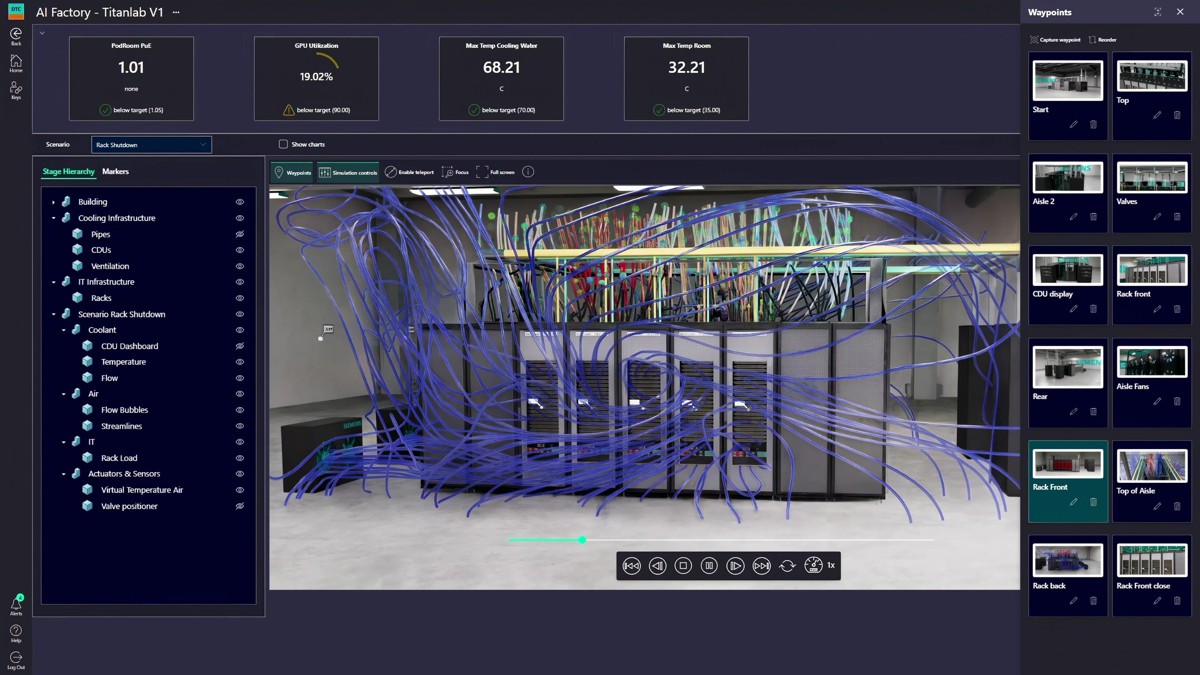

At its core, Digital Twin Composer enables industrial companies to combine 2D and 3D digital twin data from Siemens comprehensive digital twin portfolio with live physical information. These data streams are brought together in a secure, managed and photorealistic visual scene built using NVIDIA Omniverse libraries. The result is a living, high fidelity representation of an asset, process or facility that evolves alongside its real world counterpart.

Unlike traditional digital models that often become outdated soon after creation, Digital Twin Composer is designed to persist throughout the lifecycle of a product, production line or site. It continuously connects virtual design intent with operational reality, ensuring that engineering, simulation and operations teams are always working from the same contextualised source of truth.

Visualising Decisions Before They Become Reality

Digital Twin Composer provides contextualised, real time insights that allow organisations to visualise, interact with and iterate on designs long before physical construction or modification begins. Whether modelling a new smartphone production line, a tanker under construction in a shipyard, an autonomous electric vehicle programme or a next generation AI factory, users can explore options and consequences in a realistic virtual environment.

This capability changes the tempo of industrial decision making. Design alternatives that once took weeks to validate can now be tested in minutes. Automation strategies can be validated before hardware exists. Operational changes can be stress tested under real world constraints without disrupting live production. In effect, Digital Twin Composer shifts risk discovery from the physical world into the virtual one, where mistakes are cheaper and lessons arrive faster.

PepsiCo Sets an Early Benchmark

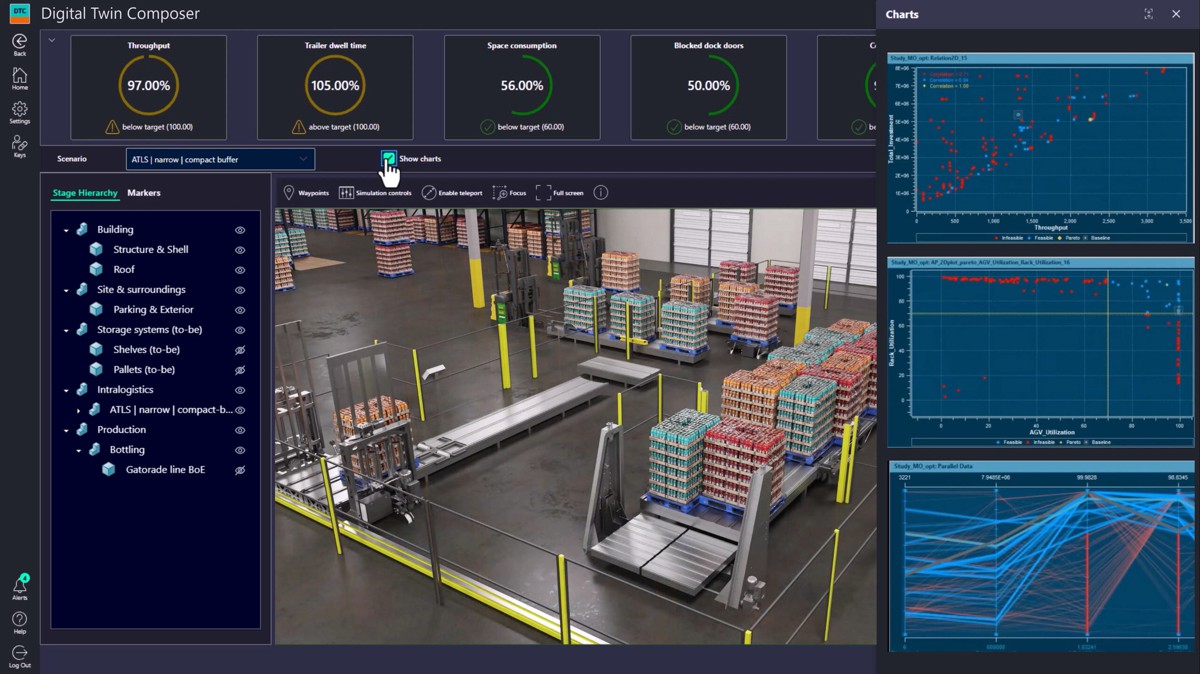

The early access deployment at PepsiCo offers a clear illustration of what this approach delivers in practice. PepsiCo and Siemens have been digitally transforming selected manufacturing and warehouse facilities in the United States by converting them into high fidelity 3D digital twins. These virtual environments simulate plant operations and the end to end supply chain, establishing a robust performance baseline.

Within weeks, cross functional teams were able to optimise and validate new configurations aimed at increasing capacity and throughput. The initiative gave PepsiCo a unified, real time view of operations while maintaining flexibility to integrate AI driven capabilities over time. What once required lengthy physical trials was instead resolved through rapid virtual experimentation.

Physics Level Accuracy Delivers Measurable Gains

By leveraging Digital Twin Composer alongside NVIDIA Omniverse and computer vision, PepsiCo can recreate every machine, conveyor, pallet route and operator path with physics level accuracy. This level of realism allows AI agents to simulate, test and refine system changes under conditions that closely mirror reality.

The results have been tangible. The approach has identified up to 90 percent of potential issues before any physical modifications were made. Initial deployments have already delivered a 20 percent increase in throughput. Design cycles have accelerated, design validation has approached full certainty, and capital expenditure has been reduced by 10 to 15 percent by uncovering hidden capacity and validating investments virtually rather than through trial and error on the shop floor.

Breaking Down Longstanding Silos

One of the most persistent challenges in industrial environments is organisational fragmentation. Design, engineering and production teams often work independently, relying on different tools and disconnected data systems. These silos slow decision making and increase the risk of costly misalignment.

Digital Twin Composer addresses this problem by unifying design, simulation and operations into a single living model. Engineers can test products, processes and facilities together. Automation can be validated long before equipment is installed. Once the physical asset exists, it can be operated and optimised using the same digital twin that guided its creation.

Delivering the Industrial Metaverse Vision

Joe Bohman, executive vice president of PLM Products at Siemens Digital Industries Software, framed the announcement as a decisive step towards a long stated ambition: “The new Digital Twin Composer delivers on our vision for the industrial metaverse. It helps manufacturers to overcome the unprecedented challenges of mastering complexity, accelerating production, reducing costs and increasing profitability.”

He added: “Siemens and NVIDIA are partnering to help manufacturers bring the most complex products, processes and factories online faster, boost resiliency and sustainability, and continuously optimise performance.” The emphasis on resilience and sustainability reflects a broader industry shift towards systems that can adapt quickly while consuming fewer resources.

NVIDIA Brings Physically Accurate Simulation

From NVIDIA perspective, Digital Twin Composer strengthens the digital thread across the industrial lifecycle. Rev Lebaredian, vice president of Omniverse and Simulation Technology at NVIDIA, explained: “In an era where every physical object and process will have a digital twin, Siemens Digital Twin Composer establishes a digital thread that connects the silos of design, engineering and operations across the Siemens Xcelerator ecosystem.”

He continued: “By integrating NVIDIA Omniverse libraries into Digital Twin Composer, enterprises can take advantage of physically accurate simulation across their workflows to validate their entire lifecycle from product design to factory logistics in the virtual world before committing a single atom to the real one.” This ability to validate decisions without physical consequences sits at the heart of the industrial metaverse concept.

Part of the Siemens Xcelerator Ecosystem

Digital Twin Composer forms part of Siemens Xcelerator, an established portfolio of industrial software used globally to design, simulate and prepare products, processes and factories at scale. Within this ecosystem, Digital Twin Composer acts as the connective layer that links high performance, photorealistic 3D digital twins with real world data sources.

These sources include manufacturing execution systems, quality management systems, programmable logic controller code and industrial internet of things data drawn from an open ecosystem of engineering tools. Additional intelligence can be unlocked through integration with Siemens data science and AI software, including RapidMiner and other AI solutions, enabling real time insights and confident decision making within the virtual environment.

Early Access Today and Broader Impact Ahead

Launched at CES 2026, Digital Twin Composer is currently available in early access with selected customers. While initial use cases are emerging in manufacturing and logistics, the underlying approach has implications far beyond the factory floor. Infrastructure projects, energy facilities, mobility systems and large scale construction programmes all stand to benefit from the ability to simulate complexity at scale before physical commitments are made.

As industrial organisations grapple with cost pressure, skills shortages and sustainability targets, the ability to test, validate and optimise in a virtual environment is moving from advantage to necessity. Digital Twin Composer suggests that the industrial metaverse is no longer an abstract concept, but a practical toolset capable of delivering measurable value today.