Blackline Safety Advances the Role of PPE in Data-Driven Worksite Safety

Across construction, infrastructure, transport and heavy industry, worker safety has quietly become a digital systems challenge rather than a compliance checklist. As worksites grow larger, more distributed and more automated, safety leaders are expected to manage risk in real time, across multiple locations, often with fragmented data and disconnected devices. That pressure has pushed connected safety technology from the margins into the core of modern operations.

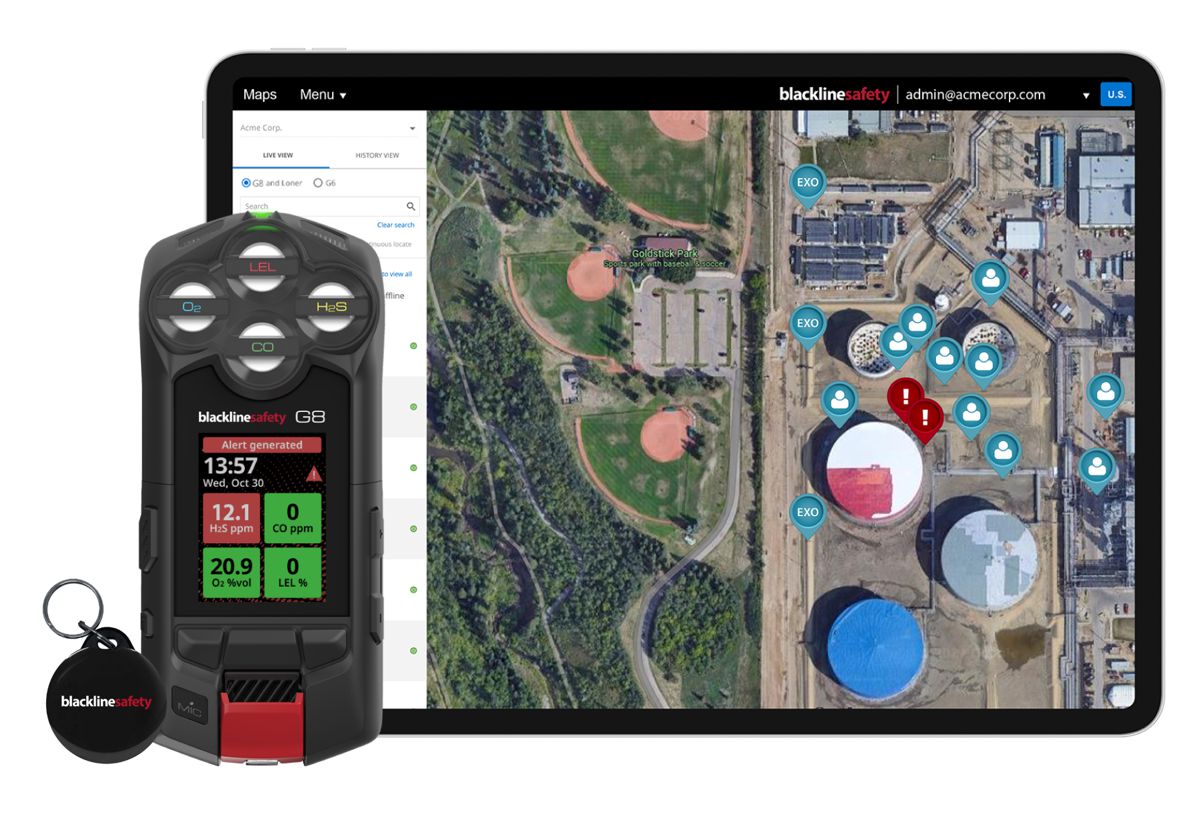

Against that backdrop, Blackline Safety Corp has introduced G8, a new connected wearable designed to consolidate gas detection, lone worker protection and communications into a single cloud-connected platform. Rather than positioning safety as a standalone function, the device reflects a broader industry shift where worker protection, operational continuity and data visibility increasingly intersect.

For infrastructure owners, contractors and industrial operators, the significance lies less in any single feature and more in what consolidation enables. Fewer devices on workers, fewer manual processes for supervisors, and more consistent data flowing into operational decision-making all point towards safety becoming an integrated layer of the digital worksite.

Why Connected Wearables Matter to Modern Infrastructure

Infrastructure projects are no longer confined to predictable, controlled environments. From tunnelling and utilities to renewables, ports and logistics hubs, work increasingly happens in remote, hazardous or high-consequence settings. Traditional safety approaches struggle to scale in these conditions, particularly when visibility is limited and response times are critical.

Connected wearables address this gap by turning individual workers into live data points within a wider operational system. Real-time gas readings, movement data and location information can be shared instantly with safety teams, allowing earlier intervention and more informed decisions. For investors and policymakers, this capability aligns closely with broader trends around digital transformation, resilience and workforce protection in critical national infrastructure.

G8 enters this landscape as an attempt to move beyond incremental upgrades. Instead of adding features to a single-purpose gas detector, Blackline has framed the device as a platform that can evolve alongside increasingly connected worksites.

Building on Proven Foundations Without Standing Still

G8 builds on the established G7 line, which has been widely deployed across industrial environments over recent years. That lineage matters in a sector where reliability, certifications and trust are earned over time rather than through bold claims.

At its core, G8 remains a fully featured connected gas detector with an IP-67 rating and intrinsic safety credentials designed for harsh industrial conditions. Swappable cartridges allow coverage of more than 20 gases, supporting use cases ranging from confined space entry to energy, utilities and chemical processing.

What differentiates G8 is the deliberate expansion beyond gas detection. By consolidating multiple safety and communication tools into one rugged device, Blackline is addressing a persistent operational challenge: workers juggling radios, gas monitors and personal safety alarms, each with its own battery, training requirements and failure points.

From Lone Worker Protection to Situational Awareness

Lone worker protection has become a priority across infrastructure and industrial sectors, particularly as maintenance and inspection tasks are pushed into more isolated locations. G8 incorporates monitoring for falls, lack of movement, health events, physical assaults and scenarios where workers may become trapped or stranded.

Location accuracy plays a critical role in making such alerts actionable. G8’s dual-band GNSS and GPS support, using both L1 and L5 signals, is designed to deliver faster time-to-first-fix and location accuracy within approximately one metre. In complex environments where satellite visibility is compromised, that improvement can make the difference between rapid response and costly delays.

The integration with ZoneAware geofencing through the Blackline Live platform adds another layer of situational awareness. By defining site zones and visualising who is where, safety teams can identify bottlenecks, manage access to hazardous areas and accelerate muster drills during evacuations.

Communication as a Safety Multiplier

Communication failures are a recurring factor in serious incidents across construction and industrial worksites. G8 addresses this through three distinct communication modes that support both emergency response and everyday productivity.

Push-to-Talk functionality provides radio-style communication across sites, regions or even countries, removing reliance on local radio infrastructure. Emergency voice calling connects workers directly with live monitoring agents when alerts are triggered, reinforcing the value of human oversight in critical situations. Text messaging allows for both pre-set and custom messages, supporting mass notifications during evacuations, severe weather or operational disruptions.

Hardware design underpins these capabilities. An internal full-range speaker delivering up to one watt of audio power is intended to ensure alerts remain audible in noisy environments, while an optional remote speaker microphone extends output further for particularly challenging conditions.

Design Choices That Reflect Real-World Use

Usability is often underestimated in safety technology, yet it has a direct impact on adoption and effectiveness. G8 introduces a 64-colour backlit display that is approximately double the size of its predecessor, using a reflective active-matrix TFT LCD with nearly 77,000 pixels. The goal is clear visibility of alerts and status information at a glance without compromising battery life.

Practical features such as NFC TagAssign allow instant device assignment with a single tap, reducing friction at shift changes. A built-in 35-lumen flashlight supports work in low-light or confined spaces, acknowledging the everyday realities of industrial environments rather than focusing solely on headline specifications.

These design decisions may appear incremental individually, but together they point to a device shaped by field use rather than lab assumptions.

Real-Time Data as an Operational Asset

The strategic value of G8 is most evident in its continuous data streaming to Blackline Live. By transmitting live data via the cloud, the platform provides safety leaders with immediate visibility into worker status, gas exposures and site conditions.

For operations teams, this data supports more than incident response. Patterns in alerts, location data and environmental conditions can highlight inefficiencies, inform planning and reduce unplanned downtime. In large infrastructure projects, where delays carry significant financial consequences, the ability to anticipate issues rather than react to them represents a tangible commercial advantage.

This approach aligns with wider industry adoption of data-driven decision-making, where safety metrics increasingly sit alongside productivity and performance indicators.

A Platform Designed for Integration and Growth

One of the more consequential aspects of G8 is its positioning as a future-ready platform rather than a closed device. Traditional gas detectors tend to operate in isolation, generating data that is difficult to integrate with broader digital systems.

G8 is designed to connect with other enterprise platforms already used across infrastructure projects, including human resource management systems, field service management tools and hot-permitting applications. By reducing manual workflows and duplication, such integrations can lower administrative burden while improving data consistency.

Automatic firmware updates further reinforce this platform mindset. Rather than being locked into a fixed feature set, G8 is intended to evolve with new capabilities, expanded integrations and emerging technologies, including AI-driven insights and predictive analytics.

“We’re talking about a platform built to grow with you,” said Phil Benson, VP, Product, Blackline Safety: “As worksites become more connected, automated and data-driven, G8 has the flexibility to meet tomorrow’s needs, not just today’s. It lays the foundation for future capabilities like AI integrations, expanded calling features, and predictive analytics that will continue to raise the bar for connected work for years to come.”

Leadership Perspective on a Changing Safety Landscape

The strategic intent behind G8 is reflected in how Blackline’s leadership frames the device. Rather than focusing on specifications alone, the emphasis is on enabling faster, safer decisions across increasingly complex worksites.

“G8 gives workers access to the tools and information they need to confidently get the job done and get home safe,” said Cody Slater, CEO and Chair, Blackline Safety: “By unifying gas detection, real-time monitoring, and communication in one connected device, we’re delivering more than incremental improvement. We’re giving every worker a direct line to the people, data, systems and support they need to make faster, safer decisions.”

For policymakers and regulators, this perspective aligns with broader objectives around reducing incidents while maintaining productivity. For investors, it underscores how safety technology can support operational resilience and long-term asset performance.

Implications for the Global Construction and Infrastructure Ecosystem

The introduction of G8 reflects a wider evolution in how safety is perceived across the built environment. As infrastructure projects incorporate more automation, digital twins and remote monitoring, worker safety technology must integrate seamlessly rather than operate in parallel.

Connected platforms that unify detection, communication and analytics are likely to become foundational elements of the digital worksite. They support not only compliance and risk reduction but also workforce confidence, operational continuity and data-driven management.

With customers in more than 75 countries and a track record of billions of data points and millions of emergency alerts, Blackline Safety’s latest device arrives with a level of scale and maturity that positions it as more than a niche innovation. It represents a step towards safety infrastructure that is as connected and adaptive as the projects it protects.

Raising the Baseline for Connected Safety

As the construction and infrastructure sectors confront labour shortages, tighter margins and rising expectations around safety and sustainability, technologies that reduce complexity while increasing visibility will carry growing weight. G8 does not claim to solve every challenge, but it signals a clear direction of travel.

By treating safety wearables as evolving platforms rather than static tools, the industry moves closer to a model where protection, productivity and data intelligence reinforce each other. For those responsible for delivering and governing critical infrastructure, that shift may prove as important as any single technological feature.