AI Driven Pole Intelligence Is Reshaping Grid Resilience

Across the United States and much of the developed world, the electricity distribution network rests on a vast but often overlooked asset base. Between 180 and 200 million utility poles support overhead power lines in the United States alone, forming the backbone of the distribution grid. Many of these structures were installed decades ago, long before today’s climate pressures, electrification demands and regulatory requirements emerged. As wildfires intensify and extreme weather events become more frequent, utilities face mounting expectations to modernise and harden their networks.

In parallel, regulators and policymakers have introduced stricter compliance requirements focused on wildfire mitigation, resilience and public safety. Accurate asset data has become the starting point for almost every grid modernisation strategy, yet the industry still relies heavily on manual and labour intensive workflows to gather this information. The gap between the pace of data collection and the urgency of grid upgrades has become impossible to ignore.

This backdrop helps explain why new digital approaches to asset modelling are gaining traction. Looq AI’s launch of qPole arrives at a moment when utilities are actively seeking faster, safer and more reliable ways to understand their infrastructure. By combining geophysical reasoning with automated modelling, the technology aims to transform how distribution networks are assessed, maintained and strengthened.

Why Pole Data Has Become Mission Critical

Electricity distribution poles may look simple, yet they are complex engineering assets. Each pole supports multiple attachments, including crossarms, transformers, communication equipment and lines operating at different voltages. Their structural integrity depends on geometry, materials, load conditions and environmental exposure. A single inaccurate measurement can lead to costly design errors or unnecessary replacements.

Traditionally, utilities conduct Pole Load Analysis to determine whether poles can safely carry existing and future loads. This work underpins grid expansion, storm hardening and wildfire mitigation programmes. However, the process remains slow and inconsistent because it relies on thousands of field crews collecting data manually. Crews must often work in challenging terrain and hazardous environments, which introduces safety risks and limits productivity.

The scale of the challenge is immense. With hundreds of millions of poles requiring inspection and analysis, even small efficiency gains can translate into millions of hours saved. That reality has encouraged utilities to explore digital workflows that reduce field time while improving accuracy and consistency.

Understanding Geophysical Reasoning in Infrastructure

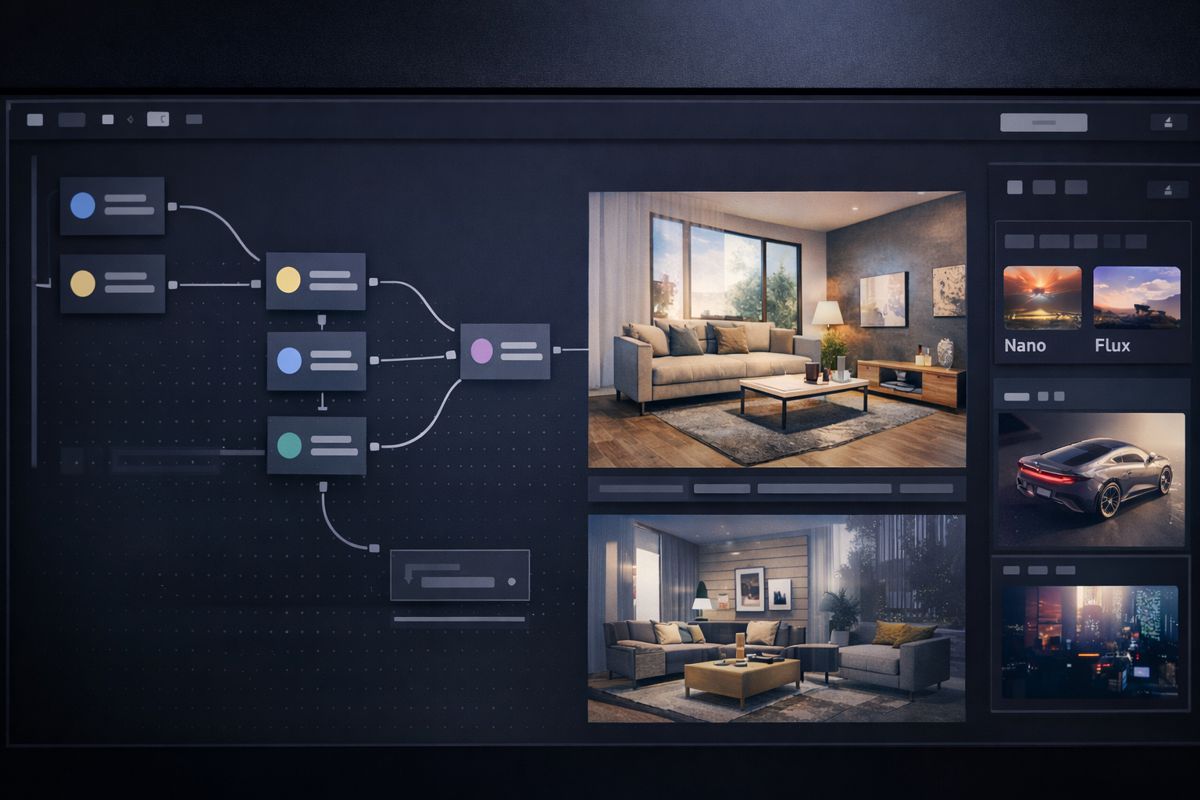

Looq AI describes its approach as geophysical reasoning, a method that enables AI models to interpret physical objects in both two and three dimensions while understanding their real world context. Rather than simply measuring distances or identifying components, the system learns to interpret infrastructure in a way similar to experienced engineers.

The concept reflects broader trends in the construction and infrastructure sectors. Digital twins, computer vision and AI driven modelling are increasingly used to analyse assets such as bridges, roads and buildings. Applying these techniques to utility poles represents a logical next step, particularly as utilities pursue data driven asset management strategies.

Dominique Meyer, CEO of Looq AI, explained the ambition behind the technology: “We have trained the computer to look at a set of images and understand the pole’s DNA—its height, diameter, material.”

This capability extends beyond simple measurement. The system identifies key components and generates engineering ready representations that can be integrated directly into design and analysis workflows.

From Manual Surveys to Automated Modelling

Capturing pole data has historically been a time consuming and potentially dangerous task. Field crews often rely on hot sticks, manual measurements and image based capture methods. Each pole typically requires around 15 minutes of fieldwork, and crews must contend with harsh weather, remote terrain and wildlife hazards.

Looq AI’s workflow aims to compress this process dramatically. Using automated capture techniques, the company claims fieldwork can be reduced to approximately two minutes per pole. The shift not only improves productivity but also enhances safety by reducing the time crews spend in hazardous environments.

Meyer highlighted the engineering implications of this approach: “Looq’s AI uses this human-like understanding to create a blueprint of a CAD model for each pole.”

By generating a digital blueprint automatically, the system provides engineers with the data needed to evaluate asset health and identify potential failure risks. This capability has significant implications for utilities seeking to prioritise maintenance and reduce outage risks.

Transforming the Back Office Workflow

Field capture is only one part of the traditional pole modelling process. Once data is collected, engineers must manually validate and process it before running analysis tools such as SPIDAcalc, O-Calc or PLS-CADD. This back office work typically adds another 15 minutes per pole, doubling the total time required.

The qPole workflow reduces this stage to approximately five minutes per pole through automated detection and modelling. By streamlining both field and office processes, the total time per pole falls from around 30 minutes to roughly seven minutes.

The productivity gains are substantial. Meyer noted the broader industry impact: “This average saving of 23 minutes per pole represents unlocking an estimated 19 million work hours saved annually in the U.S. alone.”

For utilities facing labour shortages, the ability to reallocate millions of hours toward higher value work could prove transformative. Instead of spending time on manual data entry, engineers and crews can focus on grid hardening and reliability improvements.

Addressing Labour Shortages and Skills Gaps

Workforce challenges are becoming a defining issue for the utility sector. Many experienced engineers and field technicians are approaching retirement, while demand for electrification continues to grow. Recruiting and training new staff takes time, and the pace of infrastructure upgrades leaves little room for delays.

Automation offers a way to bridge this gap. By reducing manual tasks and improving workflow efficiency, AI driven tools can help utilities maintain momentum without significantly increasing headcount. This approach aligns with broader digital transformation trends across infrastructure sectors, where technology is used to augment human expertise rather than replace it.

The potential benefits extend beyond productivity. Faster data collection enables utilities to respond more quickly to emerging risks, whether from severe weather, ageing assets or growing electricity demand. In an industry where reliability is paramount, speed and accuracy are closely linked.

Improving Accuracy and Reducing Unnecessary Costs

Precision is essential in pole modelling. Overestimating loads or misjudging structural integrity can lead to unnecessary replacements, increasing costs for utilities and ratepayers. Underestimating risks, on the other hand, can compromise safety and reliability.

Looq AI reports that its field measurements achieve sub centimetre accuracy. This level of precision supports more informed engineering decisions and reduces the likelihood of overbuilt projects. Accurate data helps utilities identify which poles genuinely require replacement and which can remain in service.

The financial implications are significant. Avoiding unnecessary replacements can save millions of dollars while reducing disruption to communities. At the same time, accurate modelling ensures that genuine risks are addressed promptly, improving public safety and network resilience.

Industry Response and Early Adoption

Early industry feedback suggests strong interest in automated pole modelling. Erik Kolb, PE, senior engineer at The Engineering Partners, Inc., commented on the technology’s potential: “EPI is excited to see the next evolution in distribution fielding with Looq AI.”

Kolb emphasised the importance of integrating new tools into existing workflows: “Our industry is primed for this exact kind of technology. We look forward to integrating our fielding practices with qPole, which will allow EPI to very quickly update its existing pole information.”

Such partnerships highlight how utilities and engineering firms are exploring new approaches to modernising infrastructure.

Audra C. Drazga, president and founder of Summit Path Advisory, also noted the broader implications: “Solutions like this have the potential to significantly improve how utilities approach asset modeling, safety, and grid reliability.”

Industry observers increasingly view automated modelling as a key enabler of grid resilience.

A Broader Shift Toward Digital Infrastructure

The launch of qPole reflects a wider transformation across infrastructure sectors. Governments and utilities worldwide are investing heavily in grid modernisation to support renewable energy integration, electrification of transport and climate resilience. Digital technologies are central to these efforts.

From satellite imagery and drones to AI driven analytics and digital twins, the infrastructure industry is embracing data driven decision making. These tools enable asset owners to monitor performance, predict failures and optimise maintenance strategies. In this context, automated pole modelling fits naturally within the evolving digital ecosystem.

The transition will not happen overnight. Utilities must integrate new technologies with legacy systems and established workflows. However, the potential benefits in efficiency, safety and reliability make digital transformation increasingly difficult to ignore.

Strengthening the Foundation of Grid Resilience

Utility poles may not attract headlines, yet they play a critical role in the reliability of electricity networks. As climate risks intensify and electrification accelerates, understanding these assets has become a strategic priority.

By combining geophysical reasoning with automated modelling, qPole offers a glimpse of how AI could reshape infrastructure management. Faster workflows, improved accuracy and enhanced safety align with the needs of utilities facing growing pressure to modernise.

For the global infrastructure community, the message is clear. Data driven asset management is moving from aspiration to reality, and technologies that accelerate this transition are likely to play an increasingly important role in the years ahead.